Setup

312062W 29

12.Ground system

a.

Reactor:

is grounded through power

cord. See page 25.

b.

Spray gun:

connect whip hose ground

wire to FTS, page 27. Do not discon-

nect wire or spray without whip hose.

c.

Fluid supply containers:

follow your

local code.

d.

Object being sprayed:

follow your local

code.

e.

Solvent pails used when flushing:

follow

your local code. Use only metal pails,

which are conductive, placed on a

grounded surface. Do not place pail on

a nonconductive surface, such as paper

or cardboard, which interrupts ground-

ing continuity

f.

To maintain grounding continuity when

flushing or relieving pressure,

hold a

metal part of spray gun firmly to the side

of a grounded

metal

pail, then trigger

gun.

13.Check hydraulic fluid level

Hydraulic reservoir is filled at the factory.

Check fluid level before operating the first

time, and weekly thereafter. See Mainte-

nance, page 44.

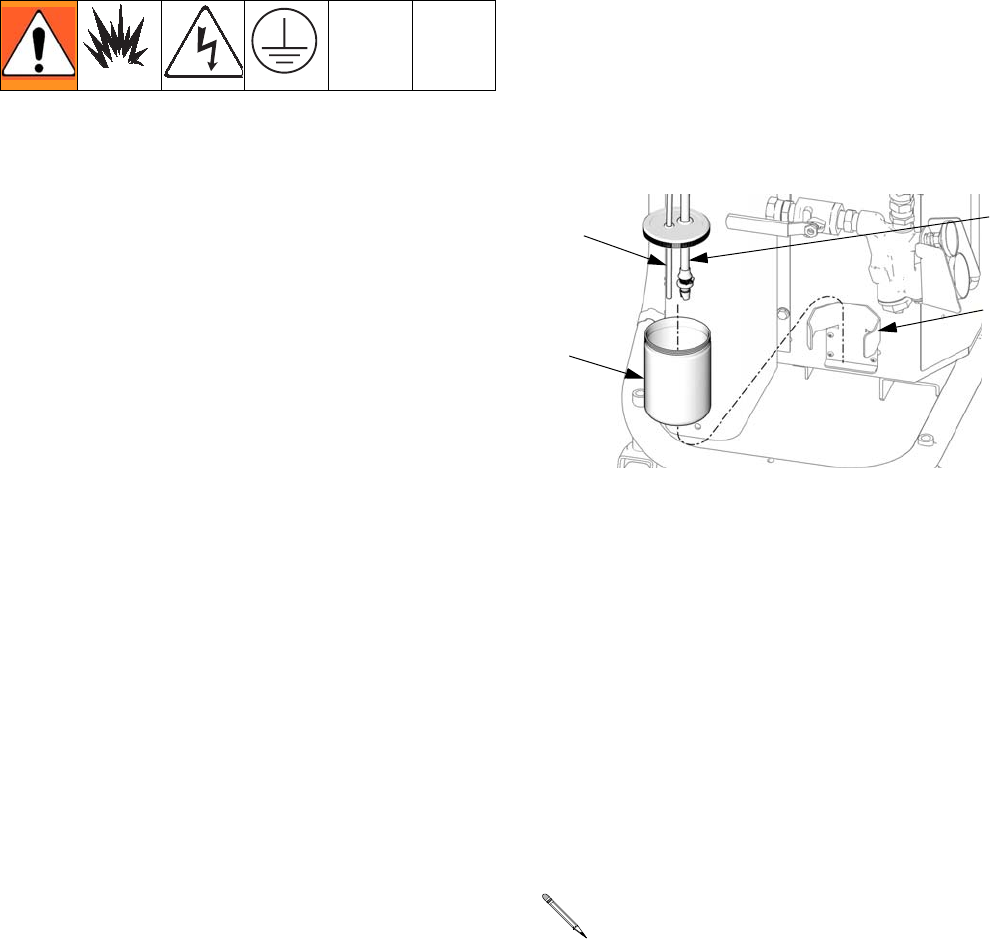

14.Lubrication system setup

Component A (ISO) Pump: Fill ISO lube

reservoir (LR) with Graco Throat Seal Liq-

uid (TSL), Part 206995 (supplied).

a. Lift the lubricant reservoir (LR) out of

the bracket (RB) and remove the con-

tainer from the cap.

b. Fill with fresh lubricant. Thread the res-

ervoir onto the cap assembly and place

it in the bracket (RB).

c. Push the larger diameter supply tube

(ST) approximately 1/3 of the way into

the reservoir.

d. Push the smaller diameter return tube

(RT) into the reservoir until it reaches

the bottom.

e. The lubrication system is ready for

operation. No priming is required.

Important: The return tube (RT) must

reach the bottom of the reservoir, to

ensure that isocyanate crystals will set-

tle to the bottom and not be siphoned

into the supply tube (ST) and returned

to the pump.

LR

RT

ST

RB

ti9911a