Maintenance

44 312062W

Maintenance

• Inspect hydraulic and fluid lines for leaks

daily.

• Clean up all hydraulic leaks; identify and

repair cause of leak.

• Inspect fluid inlet strainer screens daily,

see below.

• Grease circulation valves weekly with

Fusion grease (117773).

• Inspect ISO lubricant level and condition

daily, see page 46. Refill or replace as

needed.

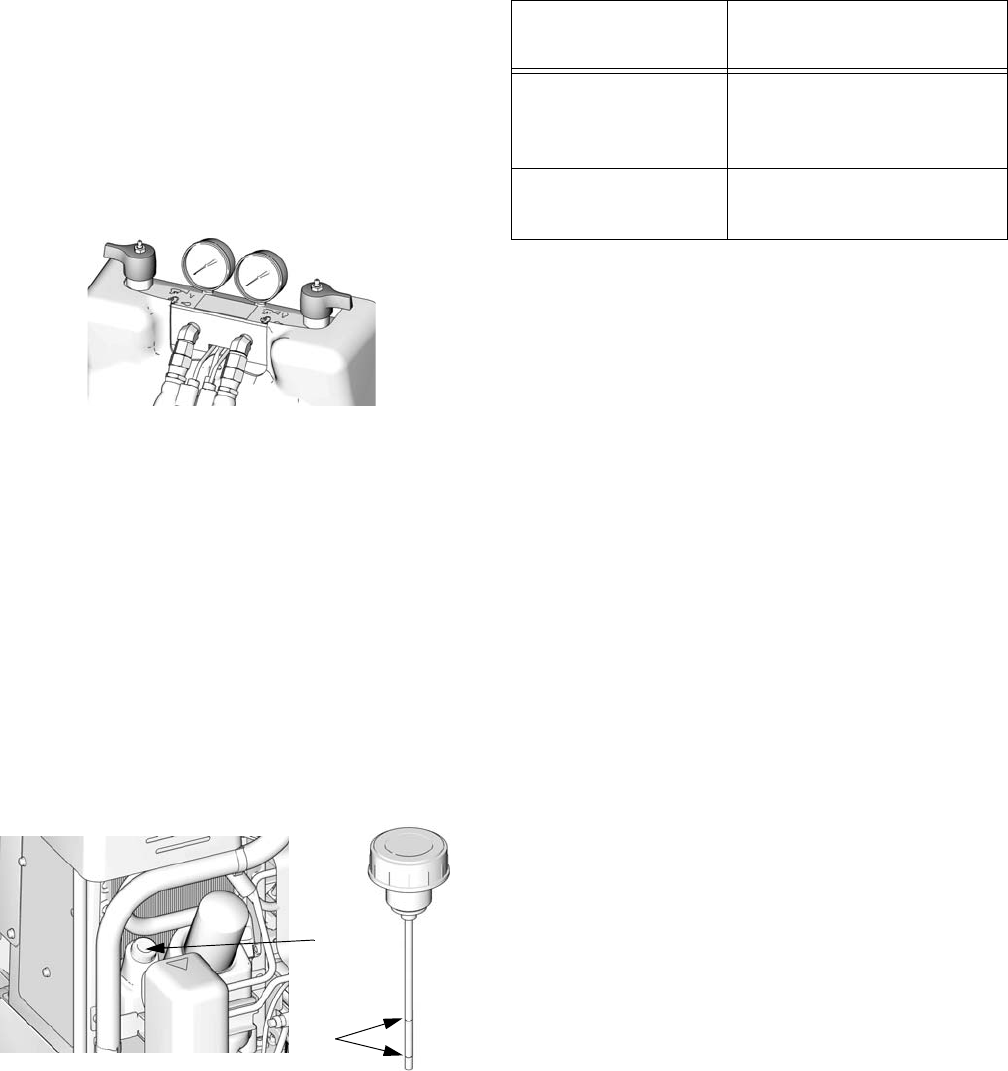

• Check hydraulic fluid level weekly. Check

hydraulic fluid level on dipstick (DS). Fluid

level must be between indent marks (IM)

on dipstick. Refill as required with approved

hydraulic fluid; see Technical Data on

page 49 and the Approved Anti-Wear

(AW) Hydraulic Oils table in the Reactor

Repair-Parts manual 312063. If fluid is dark

in color, change fluid and filter.

• Change break-in oil in a new unit after first

250 hours of operation or within 3 months,

whichever comes first. See Table 4 for rec-

ommended frequency of oil changes

Table 4: Frequency of Oil Changes

• Keep component A from exposure to mois-

ture in atmosphere, to prevent crystalliza-

tion.

• Clean gun mix chamber ports regularly.

See gun manual.

• Clean gun check valve screens regularly.

See gun manual.

• Use compressed air to prevent dust buildup

on control boards, fan, motor (under

shield), and hydraulic oil coolers.

• Keep vent holes on bottom of electrical

cabinet open.

ti9879a

S

DS

ti10003a

ti7861a

IM

Ambient

Temperature

Recommended

Frequency

0 to 90°F

(-17 to 32°C)

1000 hours or 12

months, whichever

comes first

90°F and above

(32°C and above)

500 hours or 6 months,

whichever comes first