308018 33

Service

Air Trigger Valve Repair

1. Prepare the gun for service as instructed on page

24.

2. Using a 14 mm socket wrench, remove the fluid

adjustment assembly (45), o-ring (23) and spring

(44). See Fig. 21.

CAUTION

Clean all parts in non-conductive solvent compatible

with the fluid being used, such as xylol or mineral

spirits. Use of conductive solvents can cause the gun

to malfunction.

3. Loosen the air valve packing nut (40) one full turn.

Remove the air valve shaft (39) with a pliers.

CAUTION

When removing the air valve shaft (39) be careful not

to damage the seat area.

4. Check the o-rings (41, 23) for damage and replace

if necessary. Apply petroleum jelly to the o-rings.

CAUTION

Do not over-lubricate parts. Excessive lubricant on

the o-ring (41) and air valve shaft (39) can be pushed

into the gun air passage and blemish the finish on

the workpiece.

5. Unscrew the packing nut (40) to check the u-cup

(42). Do not remove the u-cup unless it is dam-

aged.

6. Install the air valve shaft (39), with the o-ring (41),

and spring (44), into the back of the gun handle

(7). If the u-cup (42) was removed, install the air

valve shaft (39) before installing the u-cup. Install

the u-cup with its lips facing into the gun handle.

7. Install the fluid adjustment assembly (45), with the

o-ring (23). Tighten the adjustment knob (45c) with

the 14 mm socket wrench. Tighten the air valve

packing nut (40) until it bottoms.

Atomizing Air Valve Removal and

Replacement

1. Prepare the gun for service as instructed on page

24.

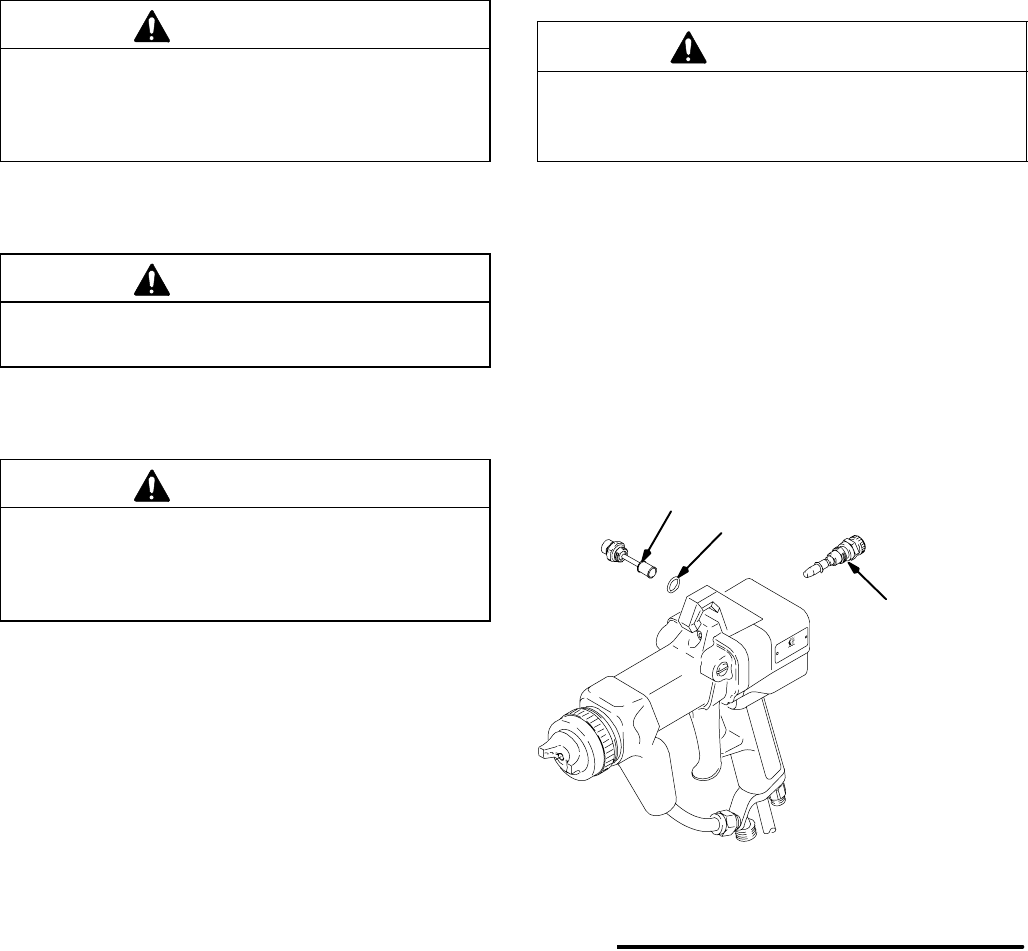

2. Remove the fan air valve (43). See Fig. 22.

CAUTION

To avoid damaging the atomizing air valve (31), the

fan air valve (43) must be removed before removing

the atomizing air valve.

3. Remove the atomizing air valve (31) from the gun

handle. Inspect the o-ring (19) and replace if

necessary.

4. Install a new atomizing air valve (31).

5. Apply PTFE paste to the fan air valve (43) housing

threads and install the valve in the handle. Torque

the housing to 10 to 12 in-lb (1.1 to 1.4 NSm).

06630

Fig. 22

43

Apply PTFE paste to the valve housing threads (43d); Torque to

10–12 in-lb (1.1–1.4 NSm)

31

19