G0456 Variable Speed Wood Lathe

-21-

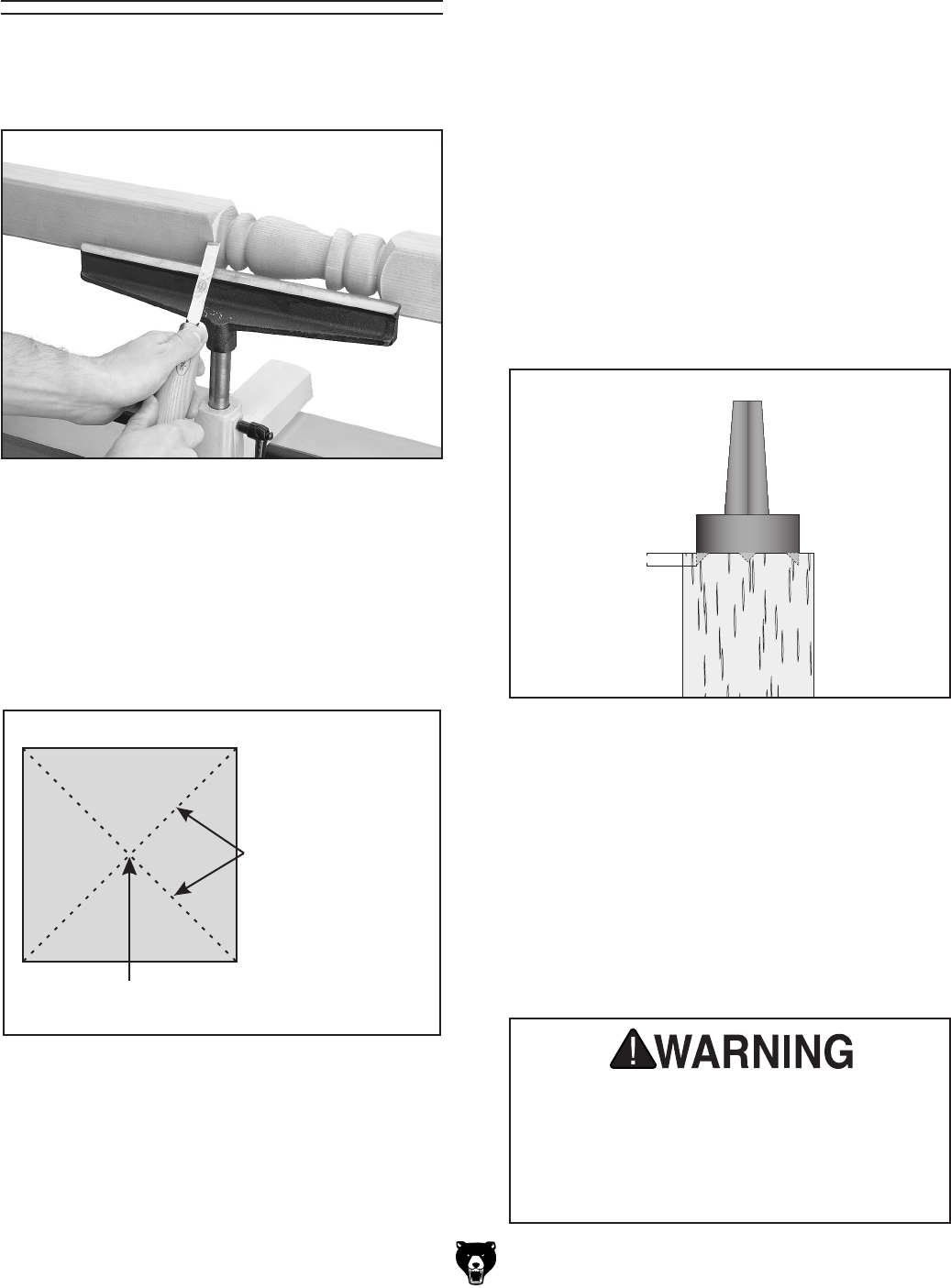

Spindle turning (Figure 22) is the operation per-

formed when a workpiece is mounted between

the headstock and the tailstock.

Spindle Turning

Figure 23. Workpiece marked diagonally from

corner-to-corner to determine the center.

Figure 22. Typical spindle turning operation.

To set up a spindle turning operation:

1. Mark both ends of your workpiece by draw-

ing diagonal lines from corner to corner. The

intersection point of these lines will show you

the center of your workpiece. See

Figure 23

for details.

Figure 24. Spur center properly embedded.

2. Using a wood mallet, tap the point of the spur

center into the center of the workpiece, so it

leaves a center mark, then remove the spur

center.

3. Using a

1

⁄4" drill bit, drill a

1

⁄4" deep hole at the

center mark. (Additionally, if the end of your

workpiece is square, cut

1

⁄8" deep saw kerfs

across the corners to help embed the spur

center.)

4. Cut the corners off your workpiece if it is over

2" x 2" to make turning safer and easier.

5. Drive the spur center into the center of the

workpiece with a wood mallet to embed it at

least

1

⁄4", as shown in Figure 24.

6. With the workpiece still attached, insert the

spur center into the headstock spindle.

7. With the live center installed in the tailstock,

slide the tailstock toward the workpiece until

the live center touches the workpiece center

-

point, then lock the tailstock in this position.

8. Use the tailstock adjustment knob to push the

live center into the workpiece at least a

1

⁄4".

Do not press the workpiece too firmly with

the tailstock or the bearings will bind and

overheat. Likewise, do not adjust too loose

-

ly or the workpiece will spin off the lathe.

Use good judgement. Serious personal

injury could result if care is not taken.