-32-

G0456 Variable Speed Wood Lathe

A misaligned headstock will not give you accurate

results and may be dangerous. This procedure

takes approximately 30 minutes to complete and

requires you to remove and discard the sandpa

-

per disc if it is installed. If you need help locat

-

ing any parts of the machine, refer to the parts

breakdown.

Tools Needed Qty

Socket or Wrench 12mm ................................... 1

Socket or Wrench

1

⁄2" ........................................ 1

Hex Wrench 6mm ..............................................

1

Hex Wrench 5mm ..............................................

1

Hex Wrench 4mm ..............................................

1

Phillips Screwdriver ...........................................

1

To check headstock/tailstock alignment:

1. DISCONNECT LATHE FROM POWER!

2. Remove the tool rest from the lathe bed.

3. With the spur center and live center installed,

slide the tailstock up to the headstock so the

tips of the centers are close to each other.

—If the tips of the centers will touch each

other, as illustrated in Figure 45, the head-

stock and tailstock are already aligned and

no further adjustments are needed.

—If the tips of the centers will not touch each

other, then the headstock needs to be

aligned with the tailstock.

Aligning Headstock

Spindle to Tailstock

Figure 45. Center tips touching to ensure

alignment.

To align the headstock with the tailstock

:

1. DISCONNECT LATHE FROM POWER!

2. Remove the table, dust port, and sandpaper

from the sanding disc.

3. Remove the left-handed cap screw in the

center of the sanding disc and slide the sand

-

ing disc off.

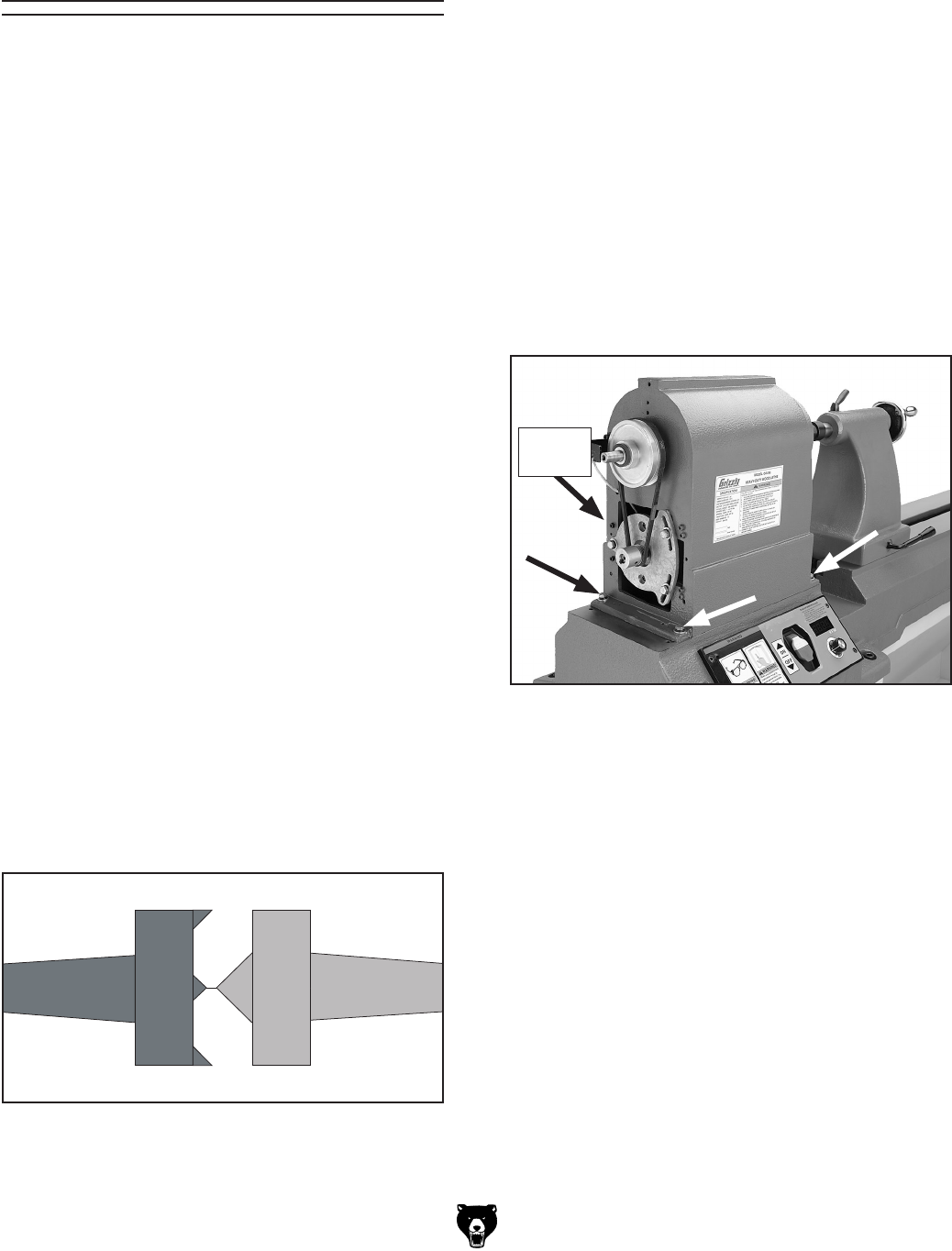

4. Remove the five cap screws (see Figure 47

on Page 33) that secure the disc housing to

the headstock, and remove the disc hous

-

ing.

—You now have access to the headstock

adjustment bolts, shown in

Figure 46.

5. Loosen the four headstock adjustment bolts,

and position the headstock so the tips of the

spur and live centers are as close as possible

to touching.

6. Tighten the headstock adjustment bolts

and reassemble all removed components in

the opposite manner from which they were

removed.

Figure 46. Headstock adjustment bolts.

Not

Shown