-30-

G0456 Variable Speed Wood Lathe

Review the troubleshooting and procedures in this section to fix your machine if a problem develops. If you

need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support

at (570) 546-9663.

SECTION 7: SERVICE

Troubleshooting

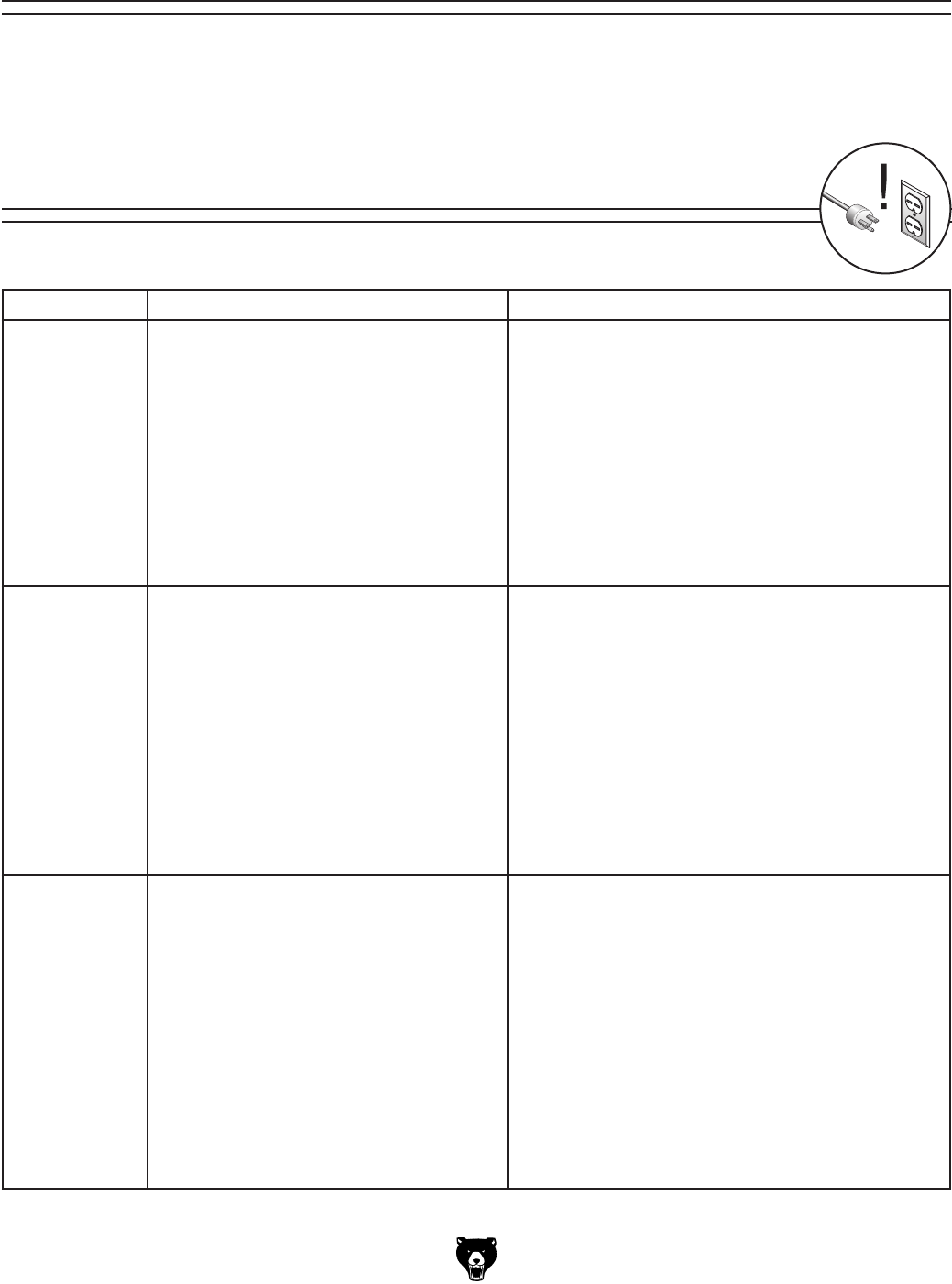

Motor & Electrical

Symptom Possible Cause Possible Solution

Machine does not

start or a breaker

trips.

1. Emergency lockout enabled.

2. Power supply is at fault/switched OFF.

3. Speed dial/rheostat is at fault.

4. Computer board is at fault.

5. Lockout key is at fault.

6. Motor brushes are at fault.

7. ON/OFF switch is at fault.

8. Wiring is open/has high resistance.

9. Motor is at fault.

1. Turn both paddle switch and speed dial

OFF. Turn

paddle switch

ON first, then turn speed dial.

2. Ensure hot lines have correct voltage on all legs and

main power supply is switched ON.

3. Test/replace if faulty.

4. Inspect computer board; replace if faulty.

5. Install/replace lockout key; replace switch.

6. Remove and replace brushes (refer to

Page 34).

7. Replace faulty ON button or ON/OFF switch.

8. Repair wiring as necessary.

9. Test/repair/replace.

Machine stalls or

is underpowered.

1. Feed rate/cutting speed too fast for task.

2. Low power supply voltage.

3. Computer board is at fault.

4. Motor speed dial/rheostat is at fault.

5. Belt(s) slipping.

6. Plug/receptacle is at fault.

7. Motor brushes are at fault.

8. Motor bearings are at fault.

9. Machine is undersized for the task.

10. Motor is at fault.

1. Decrease feed rate/cutting speed.

2. Ensure hot lines have correct voltage on all legs.

3. Inspect and replace if faulty.

4. Test and replace if faulty.

5. Replace bad belt(s), align pulleys, and re-tension.

6. Test for good contacts; correct the wiring.

7. Remove and replace brushes (refer to

Page 34).

8. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

9. Use sharp lathe bits and chisels; reduce the feed rate/

depth of cut.

10. Test/repair/replace.

Machine has

vibration or noisy

operation.

1. Motor or component is loose.

2. V-belt(s) worn or loose.

3. Sandpaper damaged, off center, or rub

-

bing.

4. Pulley is loose.

5. Machine is uneven on floor/poor mounting.

6. Workpiece or chuck (if installed) is at fault.

7. Motor bearings are at fault.

8. Spindle bearings at fault.

1. Inspect/replace stripped or damaged bolts/nuts, and

re-tighten with thread locking fluid.

2. Inspect/replace belts (refer to

Page 33).

3. Replace sandpaper evenly; adjust table-to-disc dis

-

tance.

4. Realign/replace shaft, pulley, setscrew, and key.

5. Tighten floor mounting; relocate/shim machine.

6. Center workpiece in chuck or face plate; reduce RPM;

replace defective chuck.

7. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

8. Test by rotating spindle; rotational grinding/loose shaft

requires bearing replacement.