G0588/G0591 12" Sliding Table Saws

-35-

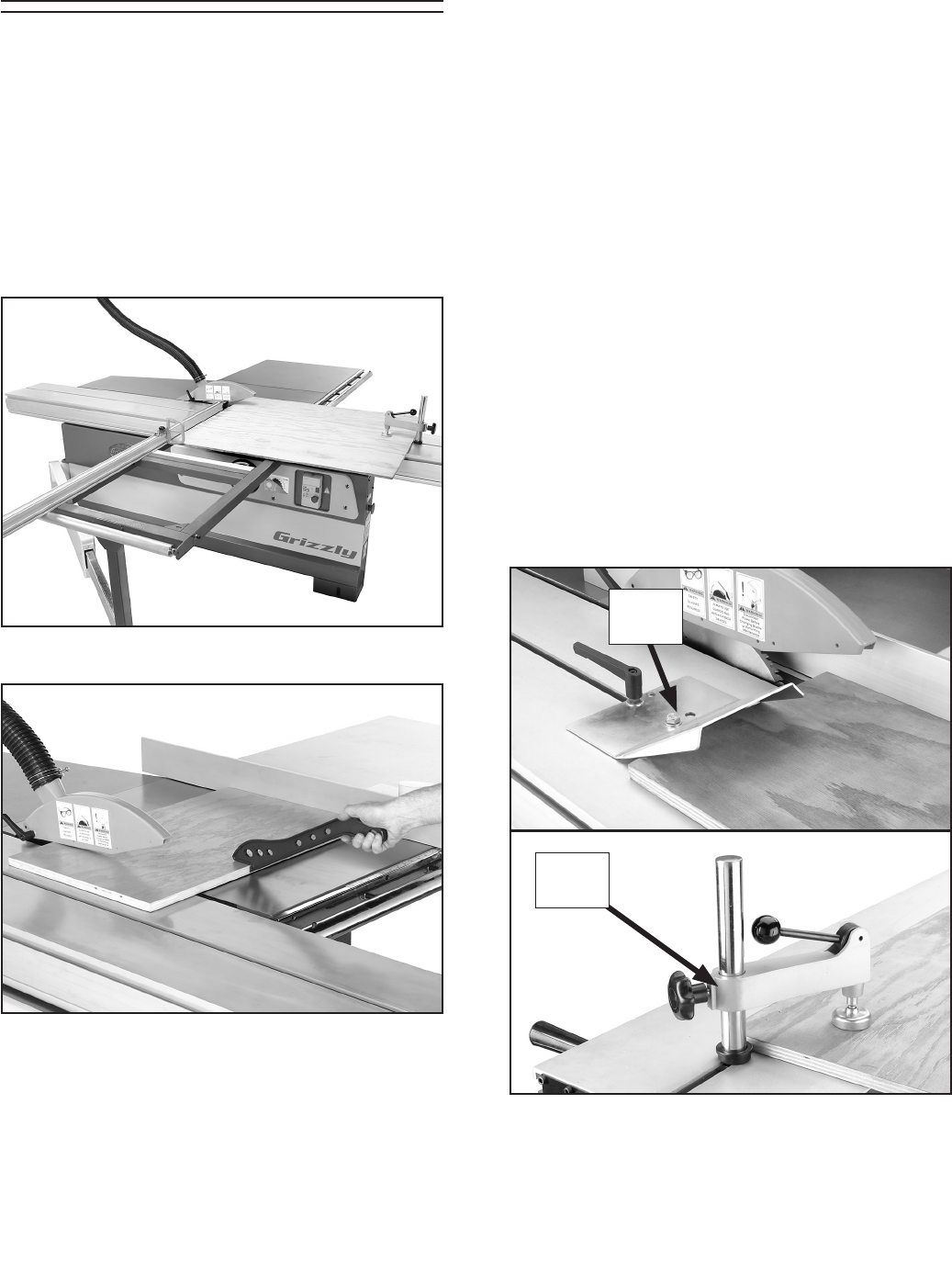

Figure 52. Edge shoe and hold down placement.

Hold

Down

Edge

Shoe

The Model G0588/G0591 easily rips full size

panels (Figure 50). The sliding table removes the

burden of sliding a large and heavy panel over a

stationary table surface.

This saw also can rip cut smaller boards using

the machine as a traditional table saw (Figure

51). Smaller, lighter boards are easier to slide

across the stationary cast iron table surface to

the right of the saw blade.

Rip Cutting

Figure 50. Rip cutting with the sliding table.

Figure 51. Traditional rip cutting.

2. Slide the protection block on the end of the

crosscut fence against the blade teeth to cali

-

brate the scale, then tighten the lock knob.

Note: The scale will not be accurate if the

protection block has been cut.

3. Set a flip stop to the desired width-of-cut.

4. Position the blade guard to the correct height

for your workpiece.

5. Load the workpiece onto the table saw. The

set up should look similar to

Figure 50.

6. When ripping irregular shaped stock, wedge

the leading edge under the edge shoe (

Figure

52), slide the hold down into place as shown

in Figure 52, and clamp the stock firmly.

Note: DO NOT use the edge shoe for rip-

ping warped or twisted boards. The tension

that causes warps and twists can cause the

board to spring free from the edge shoe and

hold down during a cut.

6. Take all the necessary safety precautions,

then perform the cutting operation.

Rip cutting with the sliding table:

1. Install the crosscut fence, align the fence to

90˚, and adjust it as instructed

on Page 48.