-18-

G1006/7 Heavy Duty Mill/Drill

Power Feed

(G1007 Only)

NOTICE

Use care when aligning the table leadscrew

gears with the gearing on the power feed.

The fit is correct when you can just slightly

wiggle one gear without engaging the other.

If there is too much space between the

gears, teeth can be stripped under heavy

loads. If the teeth mesh too tightly, the sup-

porting bearings in the power feeder will

wear out quickly.

Figure 11. Clamping bracket assembly.

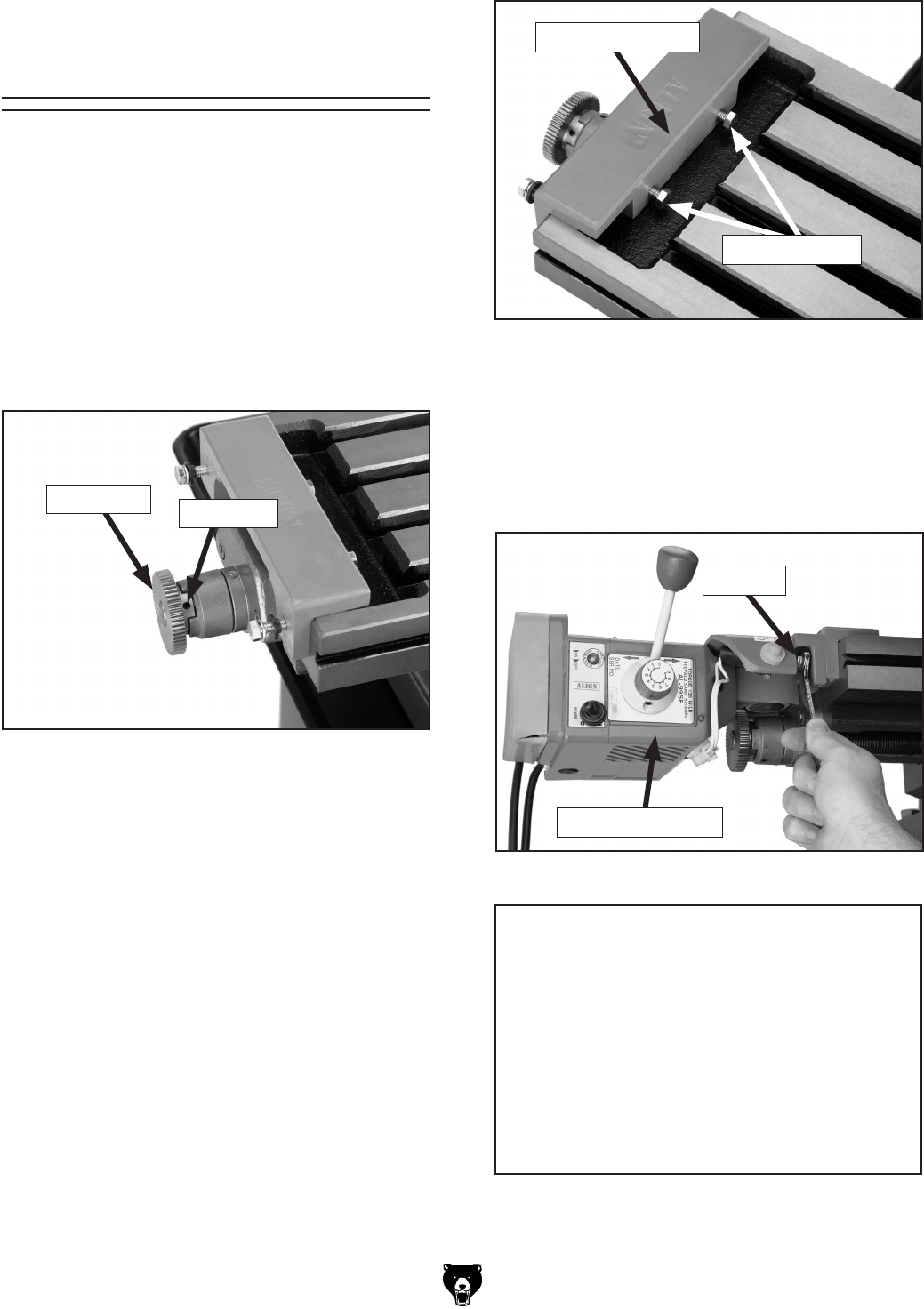

3. Attach the power feed body to the clamping

bracket assembly with the hex bolts. Before

tightening completely, position the power feed

body so the gears mesh perfectly. Tighten the

hex bolts when the gears are in mesh (Figure

12).

Figure 12. Attaching power feed body.

The Model G1007 features a 110V auto-feed

mechanism which allows hands-free, side-to-side

passes while milling. Variable-speed feed control

makes flat surface milling more consistent.

To install the power feed:

1. Attach the 2

1

/4" diameter drive gear to the left

end of the longitudinal table leadscrew. The

gear couplers on the drive gear and table

leadscrew will lock together (Figure 10).

Figure 10. Attaching drive gear.

2. Set the clamping bracket assembly on the left

end of the table. Mark the points on the table

trough where the mounting bolts contact the

table. Remove the clamping bracket assem-

bly and spot drill to give the mounting bolts

a small lip to “bite” without slipping on the

rough cast surface. Set the clamping bracket

assembly back on the end of the table and

tighten down the mounting bolts (Figure 11).

Drive Gear

Set Screw

Clamping Bracket

Mounting Bolts

Power Feed Body

Hex Bolt