-30- G1023S Series Heavy-Duty 10'' Table Saw

Ripping

To make a rip cut:

1. Set the fence to the desired width of cut on

the fence rail scale.

2. Adjust the blade height so the highest saw

tooth protrudes approximately

1

⁄4" above the

workpiece.

3. Joint one long edge of the workpiece on a

jointer.

4. Set up any safety devices such as feather-

boards or other anti-kickback devices.

5. With the saw disconnected from the

power source, rotate the blade to make

sure it does not come into contact with any of

the safety devices.

6. Plug the saw into the power source, and turn

on the saw and allow it to come to full speed.

7. The jointed edge of the workpiece must be

slide against the fence during the cutting

operation.

A rip cut is a cut with the grain direction of the

workpiece. Ripping man-made wood products

like plywood is performed by cutting parallel to

the longest side.

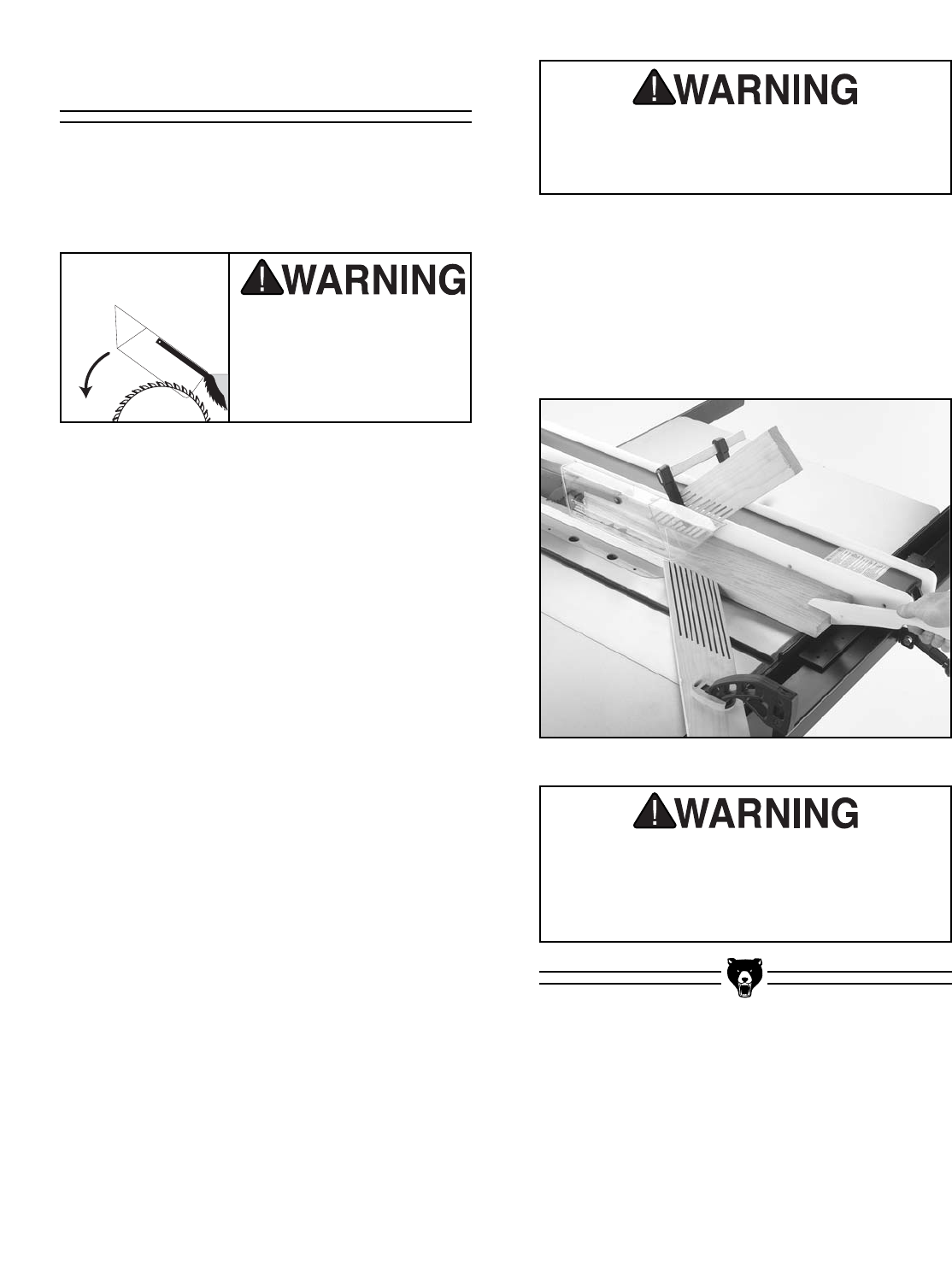

8. Using a push stick, feed the workpiece

through the saw blade as shown in Figure

31, until the workpiece is completely past the

saw blade. When a small width is to be

ripped and a push stick cannot be safely put

between the blade and rip fence, rip a larger

piece to obtain the desired piece.

Stand to the left of the blade line-of-cut

when ripping a board. Serious personal

injury could occur if kickback results.

Keep the blade guard in

the down position at all

times. Failure to do this

could result in serious

personal injury or death.

Figure 31. Typical ripping operation.

Turn off the saw and allow the blade to

come to a complete stop before removing

the cut-off piece. Failure to follow this warn-

ing could result in serious personal injury