-14-

H7761 2" x 27" Belt & 6" Disc Combo Sander

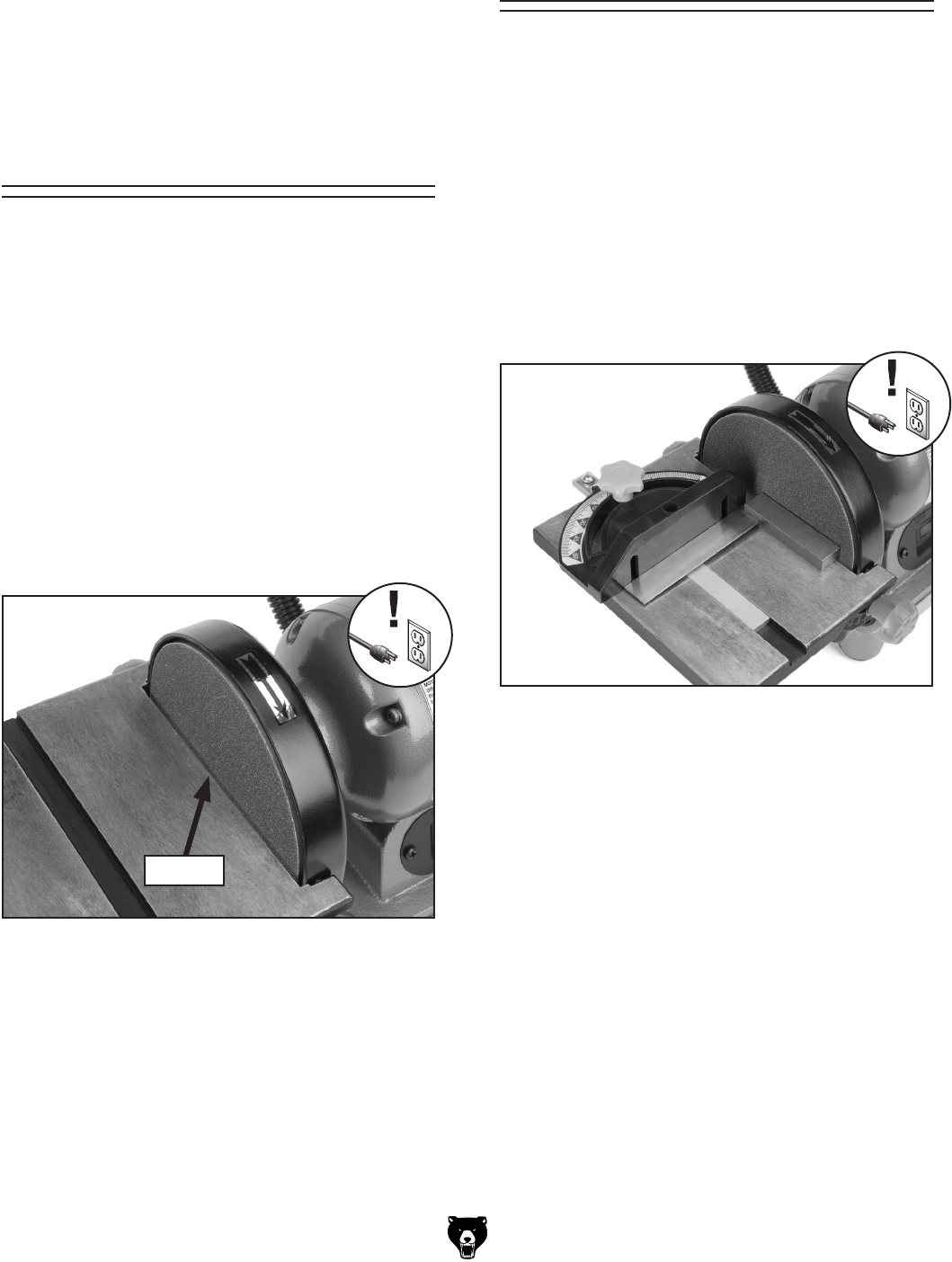

Adjusting Miter Gauge

Figure 7. Squaring the miter gauge.

The miter gauge needs to be adjusted perpendic-

ular to the face of the wheel when it is mounted

in the table slot.

To adjust miter gauge:

1. DISCONNECT THE MACHINE FROM THE

POWER SOURCE!

2. Use a machinist square with one edge

against the face of the miter gauge and

the other against the disc face as shown in

Figure 7.

3. Loosen the lock knob on the miter gauge to

adjust it flush with the edge of the square.

4. Tighten the lock knob and verify the setting.

Note: Sometimes the tightening procedure

can affect the adjustment.

5. Loosen the screw that secures the angle

pointer and adjust the pointer to the 0˚ mark

on the scale.

6. Re-tighten the screw that secures the angle

pointer.

The table must be aligned to the face of the

sanding disc so that the sandpaper does not rub

against the table.

To align the table:

1. DISCONNECT THE MACHINE FROM THE

POWER SOURCE!

2. Loosen the knobs that secure the table to the

sanding unit.

3. Adjust the table so that there is

3

⁄64" or 1 mm

between the table and the sanding disc as

shown in

Figure 6.

4. Tighten the knobs loosened in Step 2.

5. Spin the disc by hand to check if the sandpa-

per is touching the table.

6. Repeat Steps 2-4 if the sandpaper touches

the table at any point in the rotation.

Aligning Table

Figure 6. The gap between the table and the disc.

3

⁄64" Gap

3. Loosen the angle knobs and adjust the table

angle until there is no gap between the disc

face and the square.

4. Tighten the angle knobs while holding the

table perpendicular.