G1005Z Mill/Drill

-29-

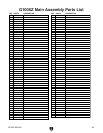

Symptom Possible Cause Possible Solution

Drill bit wobbles,

holes are over

-

sized.

1. Drill bit installed incorrectly.

2. Drill bit is bent.

1. Remove drill bit and reinstall.

2. Replace drill bit.

Tool slips in

collet.

1. Collet is not fully drawn up into spindle taper.

2. Wrong size collet.

3. Debris in collet or in spindle taper.

4.

Taking too big of a cut.

1. Snug up draw bar.

2. Measure tool shank diameter and match with

appropriate diameter collet.

3. Remove all oil and debris from collet and spindle

taper.

4. Lessen depth of cut and allow chips to clear.

Breaking tools or

cutters.

1. RPM and or feed rate is too fast.

2. Cutting tool getting too hot.

3.

Taking too big of a cut.

1. Use tables to set correct RPM and feed rates

.

2. Use cutting fluid or oil for appropriate application.

3.

Lessen depth of cut and allow chips to clear.

Machine is loud

when cutting

,

overheats or

bogs down in the

cut.

1. Excessive depth of cut.

2. Dull cutting tools.

3.

RPM and feed rate too high.

1. Decrease depth of cut.

2. Use sharp cutting tools.

3.

Use appropriate RPM and feed for the job.

Workpiece

vibrates or

chatters during

operation.

1. Table locks not tight.

2. Spindle lock not tight.

3.

Workpiece not securely clamped to table or

into mill/drill vice.

4.

RPM and feed rate too high.

1. Tighten down table locks.

2. Tighten spindle lock.

3.

Check that clamping is tight and sufficient for the

job. Make sure mill/drill vice is tight to the table.

4.

Use appropriate RPM and feed for the job.

Table hard to

move.

1. Table locks are tightened down.

2.

Chips have loaded up on bedways.

3. Bedways are dry and in need of lubrication.

4. Longitudinal stops are interfering.

5.

Gibs are too tight.

1.

Make sure table locks are fully released.

2. Frequently clean away chips that load up during

milling operations.

3. Lubricate bedways and handles.

4.

Check to make sure that stops are loose and not

hitting the center stop.

5.

Loosen gib screw(s).

Bad surface fin

-

ish.

1. Wrong RPM or feed rate.

2. Dull cutting tool or poor cutting tool selection.

3. Wrong rotation of cutting tool.

4. Workpiece not securely clamped.

1. Adjust for appropriate RPM and feed rate.

2. Sharpen cutting tool or select a better cutting tool

for the intended operation.

3. Check for proper cutting rotation for cutting tool.

4. Secure properly.