Page 27For technical questions, please call 1-800-444-3353.SKU 98871

SAFETYSERVICE BASIC WELDINGWELDING TIPS SETUP

TROUBLESHOOTING (continued)

IMPORTANT!

Be CERTAIN to shut off the Welder, disconnect it from power, and discharge the Gun to ground

before adjusting, cleaning, or repairing the unit.

Power switch (7a) lights,

but welder does not function when switched on

POSSIBLE CAUSES AND SOLUTIONS

Tripped thermal protection device: 1.

Shut the welder’s switch to off and allow it to cool for at least 20 minutes.

Reduce duration or frequency of welding periods to help reduce wear on the welder.

Refer to section on page 16.

Faulty or improperly connected Trigger (1c): 2.

Qualiedtechnicianmustcheckandsecure/replaceTrigger(1c).

Internal fuse blown: 3.

Check/replace according to the following directions.

WARNING! Turn the welder OFF and unplug it before proceeding.a.

Press on the Cover Latch (8), then lift the Cover (31) using Handle (30). Remove Left b.

Side Panel (13).

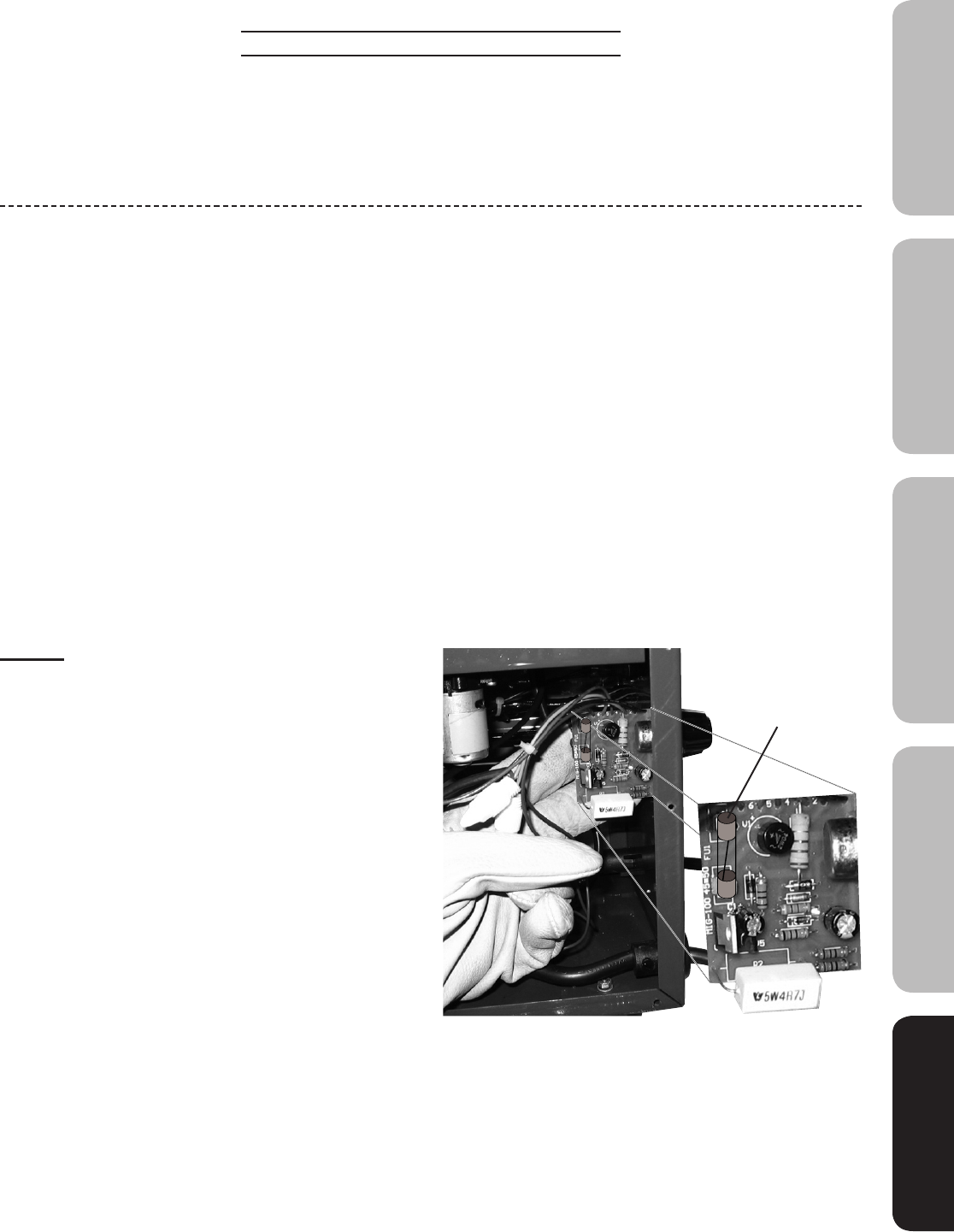

c. Examine fuse on panel to see if metal wire inside is broken or not. See illustration.

NOTE: The circuit board is and

will be damaged if it is not supported

while the fuse is manipulated. If you

are have any doubts about doing this

without damaging the welder, have a

qualied technician replace the fuse.

If the fuse is broken, carefully support the

d.

circuit board with a gloved hand while you

remove the old fuse. Support the circuit

board from behind while you install a new

2 Amp, 250 Volt fuse of the same type.

NEVER use another type or size fuse.

Reinstall the Left Side Panel (13), close

e.

the Cover (31), and test the unit for

proper function before use.

Fuse