58

15 Accessories

BLADE GUARD CONVERSION KITS:

Use the proper size blade guard for the particular diamond

blade size being operated. The following blade guards

are available for these diamond blade sizes:

Guard Blade Sizes

60” (1500mm) 48” - 60” (1200 - 1500mm)

48” (1200mm) 36” - 48” (1000 - 1200mm)

42” (1000mm) 30” - 42” ( 750 - 1000mm)

36” ( 900mm) 24” - 36” ( 600 - 900mm)

30” ( 750mm) 18” - 30” ( 450 - 750mm)

26” ( 600mm) 14” - 26” ( 350 - 650mm)

18” ( 450mm) 14” - 18” ( 350 - 450mm)

See Blade Size Conversion charts for specific

information.

WEIGHT KITS:

Standard as on: 42” (1000mm), 48” (1200mm) &

60” (1500mm).

16 Large Diameter Models

The FS8400 can be congured with a 60” (1500mm)

diameter blade capacity. The 60” drive can be ordered

from the factory or can be recongured by ordering the

conversion kit 542 19 96-25. See the Blade Size Conversion

Chart for specics. Depth of cut of 25” can be achieved.

The large diameter model includes a frame extension,

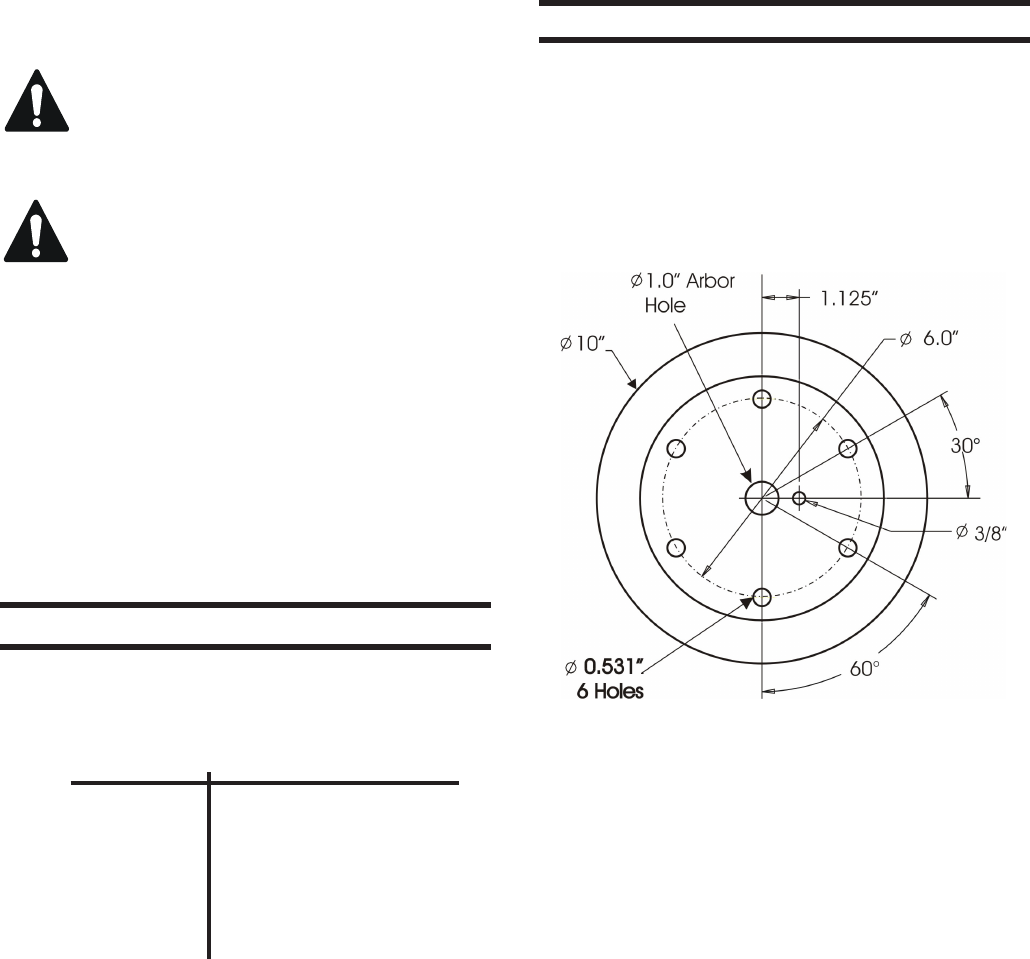

60” blade guard and a blade shaft assembly with 10”

diameter flanges. The Flanges have the following

pattern.

The Blade Hole pattern must match. Six (6), ½-13 x

2.5” long Hex Head Cap Screws pass through the outer

ange through the blade core and thread into the inner

ange supplying the clamping force to hold the blade.

Use ½” lock washers with the clamping bolts. Also use

the 5/8-11 x 4.0” Cap Screw, LH or RH thread through

the center of the ange. Husqvarna will supply blades

with this hole pattern.

The FS8400, when equipped with a 60” drive system is

very heavy and the machine balance is greatly affected

by installing or removing a blade. To counter the large

balance changes, a weight box is mounted on the left or

right rear of the saws. Weights can be easily removed

and added to quickly adjust the machine balance to meet

the operator’s needs.

542 19 61-72 Kit, Rear weights 2 Bars 42”

542 19 80-22 Kit, Rear weights 3 Bars 48”

542 19 97-57 Kit, Rear weights 6 Bars 60”

(includes: Side weights) 5 Bars w/ handles

OPTIONAL KITS:

542 18 11-17* Dual Light Kit

542 19 96-26 Water Pump Kit

c) Change the ENGINE GEARBOX PULLEY from 4.75”

(121mm) diameter to 4.12” (105mm).

d) Shift the GEARBOX SHIFT LEVER (3-2O) from

2 to 1.

e) Verify that machine drive conguration and blade

shaft speed corresponds with 20-36 drive conguration

information in operation manual.

f) Install the 20-36 drive conguration decals (Decals

504 11 98-09, 542 20 65-49 are required). See the “Decals

and Locations” page of this manual for more information.

See Blade Size Conversion charts for specific

information.

WARNING: Serious injury can occur to the

operator or people in the work area if the

rotational speed (n/min) of the DIAMOND

BLADE (2E) exceeds the maximum speed

(n/min) marked on the DIAMOND BLADE (2E).

WARNING: After Shifting Gearbox, lower

GEARBOX DETENT KNOB (3-2P) or three-

speed ENGINE GEARBOX (3-2A) could

be damaged!

If gearbox seems hard to shift, a slight movement of the

blade shaft may ease movement of GEARBOX SHIFT

LEVER (3-2O) into proper gear. Never shift the Gearbox

(3-2A) with engine running!

Two Neutral positions are available in the Three Speed

ENGINE GEARBOX (3-2A). This gearbox can be shifted

into neutral if the blade rotation needs to be eliminated

while the engine is running. If the machine is equipped

with the optional BLADE CLUTCH (1V), the BLADE

CLUTCH SWITCH (1V) can be moved to the “0” (OFF)

position to eliminate blade rotation while the engine

is running.