14

Chisel Parallel to Workpiece

For accurate mortise cuts, the chisel must be

parallel to the workpiece. The workpiece should

be cut square for this adjustment to be accurate.

Check and adjust this parallelism as follows:

1. Move the head forward far enough that the

workpiece can be inserted between fence

and chisel.

2. Slightly loosen the set screw to allow the

chisel to be rotated.

3. Move the head back carefully until the face

of the chisel rests against the workpiece, but

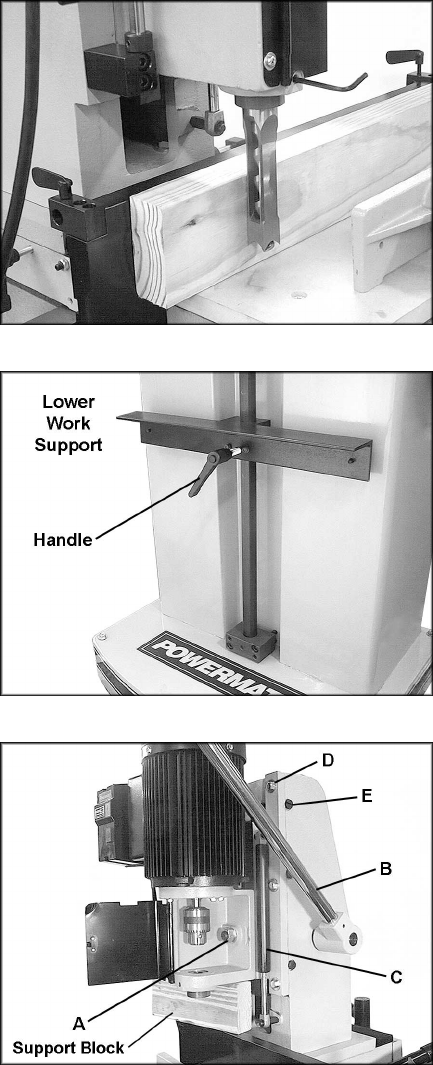

do not force. See Figure 15.

4. If needed, further adjust the chisel by hand.

5. Tighten set screw, making sure the chisel

maintains contact with the bushing.

Lower Work Support

To use the lower work support, remove the table

(see “Table Removal and Storage”). Loosen the

locking handle (Figure 16) and slide the lower

work support into position. Re-tighten the handle

securely.

Re-setting the Head

The head can be adjusted in order to achieve

the maximum workpiece height.

1. Place a block of wood for support between

the head and fence (Figure 17). Lower the

head until it rests upon the block.

2. Loosen only slightly the hex nut (A, Figure

17).

3. Pull down the handle (B, Figure 17) until the

cylinder (C, Figure 17) bottoms out.

4. Tighten the hex nut (A, Figure 17).

Gib Adjustment

The tightness of the gibs has been set at the

factory and should not require adjustment. As

parts wear through long-term use, or “play”

develops in the gib, adjustments can be made

as follows. NOTE: Gib tightness should be just

enough to allow smooth movement without

binding.

Gib for Vertical Movement

1. Slightly loosen the three hex cap screws (D,

Figure 17) which hold the gib.

2. Turn the gib screws (E, Figure 17) until any

play is removed.

3. Re-tighten the hex cap screws (D, Figure

17) securely.

Figure 15

Figure 16

Figure 17