18

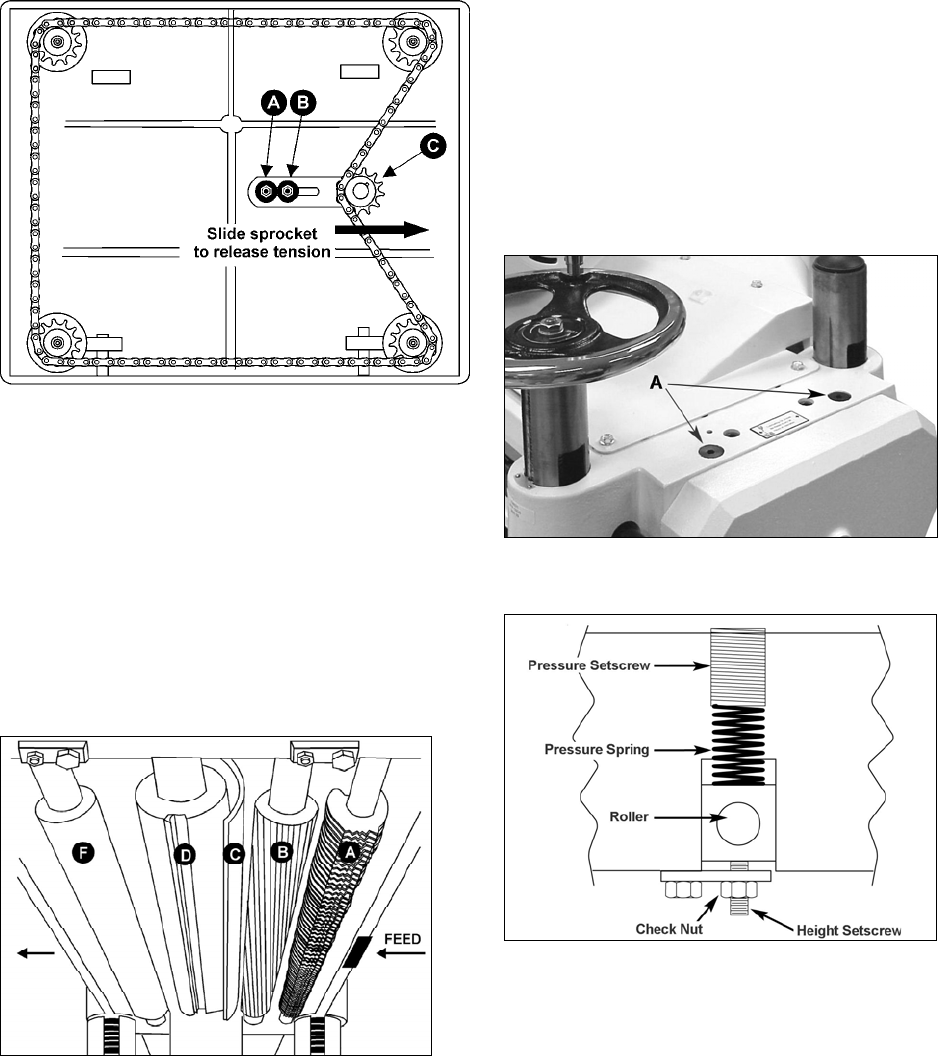

Figure 27

Transmitting Rollers

Figure 28 show the positions of the rollers that

are listed below and described in the following

sections.

A Anti Kickback Fingers

B Infeed Roller

C Chipbreaker

D Cutterhead

F Outfeed Roller

Figure 28

Infeed & Outfeed Roller Spring

Tension Adjustment

The infeed roller (B, Fig. 28) and outfeed roller

(F, Fig. 28) feed the stock while it is being

planed. The infeed and outfeed rollers are under

spring tension and this tension must be sufficient

to feed the stock uniformly through the planer

without slipping but should not be so tight that it

causes damage to the board and/or the rubber

coating on the outfeed roller. The tension should

be equal at both ends of each roller.

To adjust the spring tension of the infeed and

outfeed rollers, turn screws (A, Fig. 29) with a

hex wrench. A clockwise turn increases tension

on the pressure spring (Fig. 30); a

counterclockwise turn decreases tension. Adjust

the screws at the other end of the rollers with the

same number of turns.

Note: The most effective pressure settings are

dependent on the type of lumber being planed.

Experimentation will determine the best settings.

Figure 29

Figure 30

Anti-Kickback

The JWP-16OS Planer provides an anti-

kickback safety feature. The anti-kickback

fingers hang from a rod suspended across the

front of the cutterhead casting (A, Fig. 28) and

help prevent kickback of stock. It is necessary to

inspect them regularly to make sure they hang

freely. Check that they are free of gum and pitch

to insure independent movement and correct

operation.