TROUBLE PROBABLE CAUSE SOLUTION

When drilling metal, it is a good practice to keep the

workpiece lubricated. This prevents galling and eventual seizing of the drill

bit. Some drill bit models have accessories that automatically lubricate the

metal workpiece. Call Alltrade Customer Service at 1-800-590-3723 to see if

a lubricating accessory is available for this particular drill press.

6. Slowly reverse the feed handles until the drill bit has been cleanly removed from

the workpiece.

7. Turn the drill press ON/OFF switch to the “OFF” and remove the yellow plastic

lock key.

MAINTENANCE AND CLEANING

Turn the drill press “ON/OFF” switch to the “OFF” position and remove the

YELLOW SECURITY KEY before attempting any maintenance on this tool.

Failure to adhere to this Warning could result in damage to the drill press

and severe injury or even death to the operator.

Should the AC power cord become cut or frayed in any manner REPLACE IT

IMMEDIATELY. Any fraying is a POTENTIAL FIRE HAZARD as well as source

for severe electrical shock. Should the AC power cord be damaged near the

motor and need to be replaced, contact Alltrade Customer Service at 1-800-

423-3598 (toll free). DO NOT ATTEMPT to rewire the motor.

Your KAWASAKI™ Drill Press is virtually maintenance free. The drill press should be

cleaned after every usage preventing unwanted debris from interfering new work

pieces. On a regular basis, perform the following:

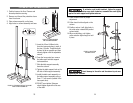

1. Use an air hose and blow any dust that may accumulate in the motor. This is

very important if you use the drill press on metal work pieces.

2. Brush all dust and debris away from the worktable.

3. Apply a coat of furniture-type paste wax to the worktable surface and the col-

umn. This will allow the components to function better and lessen the chance of

rust forming on the metal parts.

LUBRICATION

The ball bearings in the motor are packed in grease at the factory and should require

no further lubrication.

1. Apply a thin coating of lithium grease on the table rack. The aerosol type will

work fine. This keeps the rack and the table-crank gears from binding.

Periodically, remove the grease with a solvent, such as acetone, and re-apply it.

2. Apply a thin coating of lithium grease to the surfaces of the spindle and arbor.

Noisy operation

1. Incorrect belt tension

2. Dry spindle

3. Loose spindle pulley

4. Loose motor pulley

1. Adjust Tension. See Section

Installing the Drive Belts.

2. Lubricate Spindle.

3. Check retaining nut on center

pulley. Tighten if necessary.

4. Check setscrews on motor

pulley. Tighten if necessary.

Drill bit burns

1. Incorrect speed

2. Chips not coming out of

hole

3. Drill bit dull

4. Feeding too slow

5. Not lubricated

1. Change speed.

2. Retract drill bit frequently to

clear chips.

3. Change drill bits.

4. Increase feeding.

5. Lubricate drill bit.

Drill bit leads -

holes not round

1. Hard grain in wood

2. Defective drill bit

1. Replace drill bit.

2. Replace drill bit.

Wood splinters on

underside

1. No “back-up” material

under workpiece

1. Clamp workpiece under work-

piece.

Workpiece is torn

from hands

1. Workpiece not supported

or clamped properly

1. Clamp workpiece to work

table.

Drill bit binds in

workpiece

1. Workpiece pinching drill bit

2. Excessive feed pressure

3. Improper belt tension

1. Clamp workpiece.

2. Slow feeding speed.

3. Adjust Tension. See Section

Installing the Drive Belts.

Excessive drill bit

run-out or wobble

1. Bent drill bit

2. Worn spindle bearings

3. Drill bit not properly

locked in drill chuck

4. Drill chuck not properly

installed

1. Replace drill bit.

2. Contact Alltrade Customer

Service.

3. Re-set drill bit.

4. Reinstall drill chuck. See

Installing the Drill Chuck.

Quill returns too

slow or too fast

1. Improper spring tension 1. Adjust return spring.

Drill chuck fails to

remain on arbor

spindle.

1. Dirt, grease, or oil on

inside surface of drill

chuck mounting hole or

on outside surface of

arbor spindle

1. Clean drill chuck and arbor

spindle. See Installing the Drill

Chuck.

31