(&#) '##("

&*"(P)#(

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

>20; 8=2>;=DC7>A8I4384;3'4AE824028;8CH for technical troubleshooting assistance before you proceed.

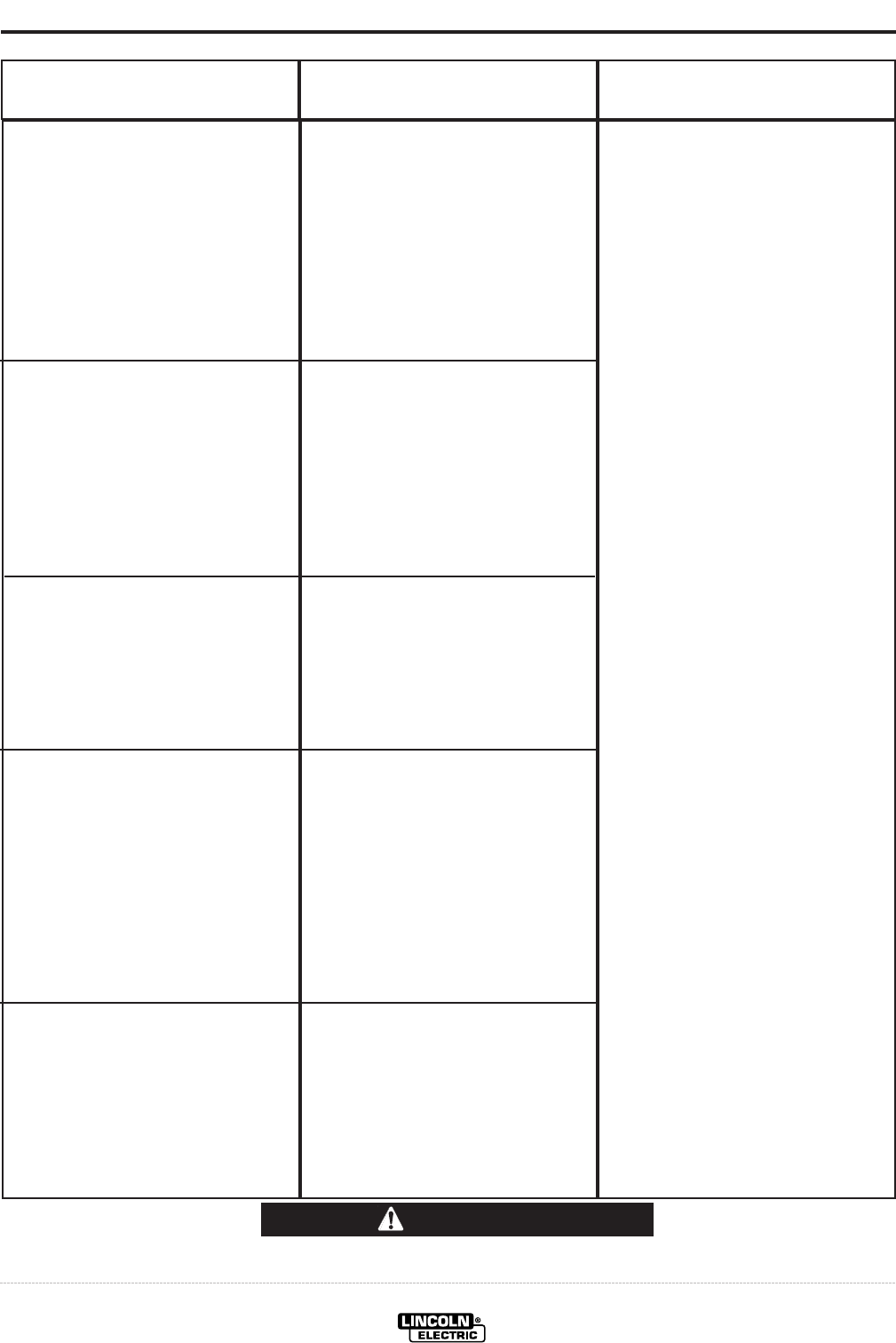

)(#"

$&# !'

'-!$(#!'

$#''

)'

&#!!"

#)&'#(#"

No welding power output.

Welder has output but no control.

Wire feeder does not work when

control cable is connected to 14 pin

connector.

No auxiliary power.

1. Poor work lead connection to

work. Make sure work clamp is

tightly connected to clean base

metal.

2. "Weld Terminals" switch in wrong

position. Place switch in "Weld

Terminals On" position when

welding without control cable.

3. Faulty PC board or welder alterna-

tor.

1. Poor remote/control cable connec-

tion to 6-pin or 14-pin connector.

Check connections.

2. Faulty remote cable or faulty wire

feeder or wire feeder cable.

Replace if necessary.

3. Faulty control potentiometer or PC

board.

1. Wire Feeder Power circuit breaker

open. Check 42V breaker and

reset if tripped.

2. Faulty control cable. Repair or

replace cable.

3. Faulty wire feeder. Replace wire

feeder.

1. Open circuit breakers. Reset

breakers. If breakers keep tripping

reduce power draw.

2. GFCI module may have tripped.

Follow “GFCI Module Testing and

Resetting Procedure” in the MAIN-

TENANCE section of this manual.

3. Faulty connections to auxiliary

receptacles. Check connections.

4. Faulty PC board or welder alterna-

tor.

I

f all recommended possible areas

of misadjustment have been

checked and the problem persists,

>=C02C H>DA ;>20; 8=2>;=

DC7>A8I4384;3'4AE824028;8CH