RANGER® 10,000 & RANGER® 10,000 PLUS

TROUBLESHOOTING & REPAIR

F-53 F-53

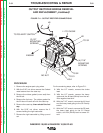

OUTPUT RECTIFIER BRIDGE REMOVAL

AND REPLACEMENT

(continued)

12. With the 1/2” wrench remove the three

mounting nuts. Note the placement of the

nylon insulators.

13. Remove the rectifier assembly by tilting it

up and lifting it toward the side of the

machine.

14. Reassembly: Refer to the Wiring Diagram

for proper connections to the positive and

negative sides of the rectifier assembly.

The two sides of the bridge are marked +

and -, respectively.

NOTE: Use Dow Corning 340 on all aluminum

electrical connection surfaces.

15. With the 1/2” wrench install the three

mounting nuts.

16. With the 7/16” socket wrench, install the

S2 lead and the heavy lead going to the S1

Range switch. Note the order of fasteners:

flat washer at the bottom followed by pig-

tails, heavy leads, flat washer, lock wash-

er, and nut.

17. With the 7/16” socket wrench, install the

W1 lead and the heavy lead going to the

S2 Polarity switch. Note the order of fas-

teners: flat washer at the bottom followed

by pigtails, heavy leads, flat washer, lock

washer, and nut.

18. With the 1/2” socket wrench, install the

heavy cable and the #8 lead (White) to the

rectifier negative heat sink. Note the order

of fasteners.

19. With the 1/2” socket wrench, install the

choke lead and the #10 lead and note the

order of fasteners.

20. Reinstall the case side, fuel cap, lift bail

gasket, case top, and spark plug wire.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC