ELECTRICAL DIAGRAMS

G-7 G-7

SCHEMATIC - ENTIRE MACHINE - CODES 10957 - 11311 PG 3 OF 3 (G4421)

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

POWER WAVE 455M/MSTT

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

EN-170

S

O

L

ID

E

D

G

E

G4421

ENGINEERING CONTROLLED

MANUFACTURER:

No

CONTROL BOARD, CHANGED 2J4 TO 3J4

G4421

INVERTER WELDERS

455M MACHINE SCHEMATIC

NONE

G4050

F.Valencic

S.Poole

.

DRAWN BY:

DESIGN INFORMATION

ENGINEER:

APPROVED:

REFERENCE:

EQUIPMENT TYPE:

SUBJECT:

SCALE:

2/1/2007

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

UF

CRM22115-GC

PAGE ___ OF ___

3

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

PROPRIETARY & CONFIDENTIAL:

F

THE INFORMATION ON THIS

PRINT IS FOR REFERENCE

ONLY. COMPONENTS AND

CIRCUITRY MAY BE

DIFFERENT

FROM AN ACTUAL MACHINE.

CHANGE DETAIL:

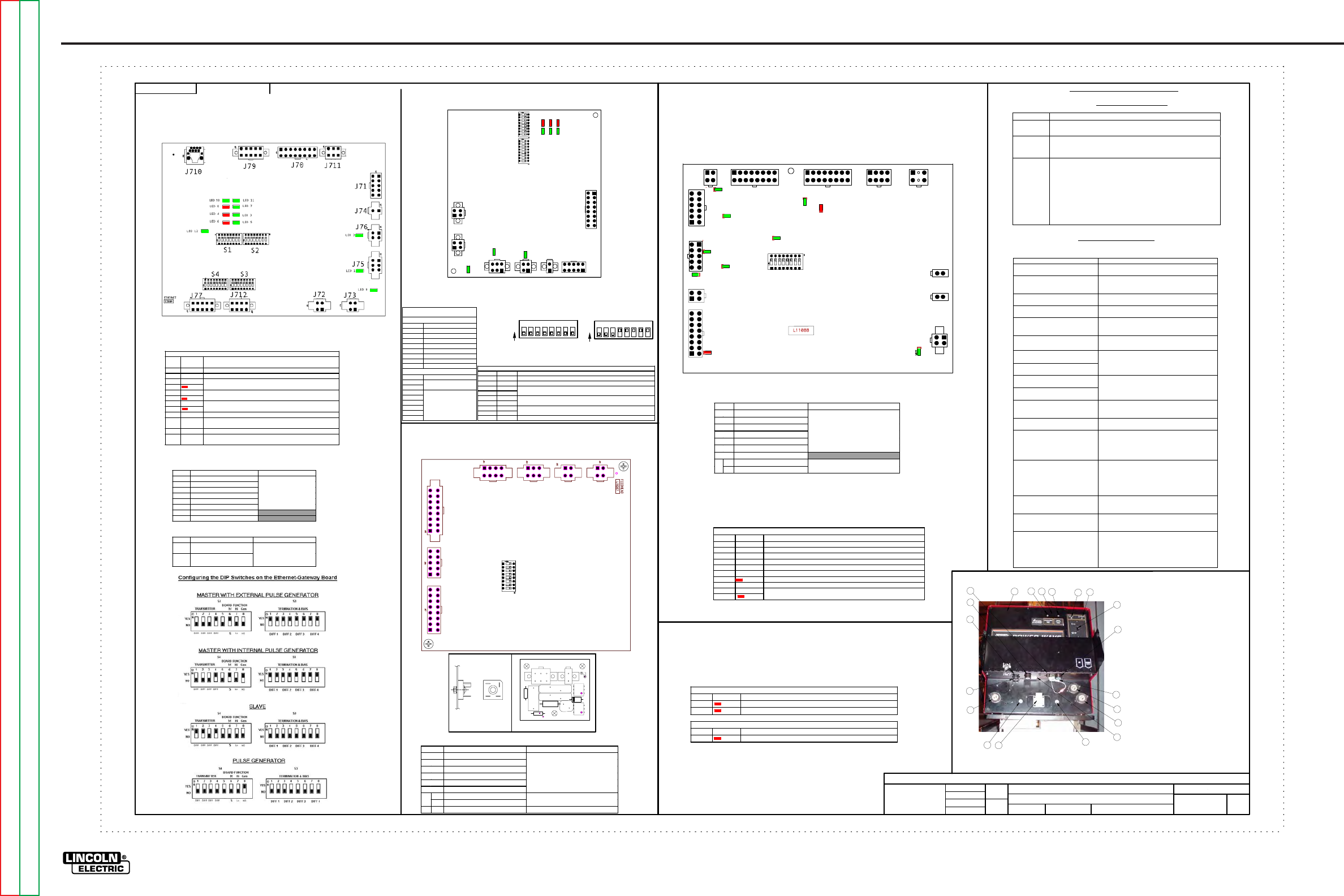

1. Power Switch

2. Status Light

3. High Temperature Light

4. 10 Amp Wire Feeder Circuit Breaker

5. Auxiliary Power Circuit Breaker

6. Work Sense Lead Connector

7. Arclink Receptacle

8. DeviceNET Connector (not shown)*

9. I/O Connector*

10. RS232 Connector

11. Work Stud

12. STT Stud

13. Electrode Stud

14. Robotic Interface Connector*

15. Auxiliary Output (110V or 220V)

16. Ethernet Connector*

17. Wire Drive Interface Module (not shown)*

18. Wire Drive Status LED*

19. Communication Interface Module (not shown)*

20. Communication Status LED*

* Not Standard in Base Model

ETHERNET MODULE

CONTROL BOARD

3

Description of LED functions on the Power Wave 455M

For reference only

L11088 Digital Control PC Board

LED # COLOR

FUNCTION

1 Green Indicates +15VDC from power supply board is present

2 Green Indicates –15VDC from power supply board is present

3 Green Indicates +5VDC for +5SPI from power supply board is present

4 Green Indicates +15VDC for +15SPI from power supply board is present

5 Green Indicates +5VDC for +5V from power supply board is present

6 Green Indicates +5VDC for +5VRS232 from power supply board is present

7 Red FAULT Signal (See software group for coding)

8 Green Indicates +5VDC for +5CAN from power supply board is present

9 Green

10 Red

ArcLink Status Indicators (Main System Master ArcLink Connection) Solid

Green only when functional (See software for error codes)

Description of LED functions on the Power Wave 455M

For reference only

G3632 Digital Power Supply Board

LED # COLOR FUNCTION

1 Red Indicates +5VDC SPI supply is present

2 Red Indicates +5VDC control supply is present

L11078 +40 Volt DC Bus Board

LED # COLOR FUNCTION

1 Red Indicates +40 VDC supply is present

Control Board DIP Switch:

stnemmoCnoitpircseDhctiwS

1

Object Instance LSB

2

Object Instance MSB

3

Equipment Group 1 Select

4

Equipment Group 2 Select

5

Equipment Group 3 Select

6

Equipment Group 4 Select

Used for Arclink configuration

7

Reserved for future use

off

work sense lead not connected

8

on

work sense lead connected

Used for configuring work sense lead

Feed Head Board DIP Switch:

stnemmoCnoitpircseDhctiwS

1 Object Instance LSB

2 Object Instance MSB

3 Equipment Group 1 Select

4 Equipment Group 2 Select

5 Equipment Group 3 Select

6 Equipment Group 4 Select

Used for Arclink Configuration

off Electrode polarity positive (default)

7

on Electrode polarity negative

Used for configuring electrode polarity

8

off Low speed gear (default) Used for confi

g

urin

g

wirefeeder

gear ratio

Ethernet Board DIP Switch :

Bank S1

Switch Description Comments

1 Object Instance LSB

2 Object Instance MSB

3 Equipment Group 1 Select

4 Equipment Group 2 Select

5 Equipment Group 3 Select

6 Equipment Group 4 Select

Used for Arclink

Configuration

7 Reserved for future use

8 Reserved for future use

Table 15

Bank S2

Switch Description Comments

1 - 2 Devicenet Baud Rate

3 - 4

Devicenet Mac ID

Used for DeviceNet

configuration

J75

J76

J74

J71

J73

J72

J70

GATEWAY

L11046

DEVICENET MODULE

J72

J73

J75

J76

J74

J71

J70

(OPTIONAL K2206)

S1

S2

LED6

LED4

LED8

LED5

LED3

LED7

LED2

LED1

LED9

Case Front Detail

1

2

3

18

17

20

8

7

6

16

11

4

15

5

12

13

10

9

14

Power Wave 455M/STT CE

(shown with Wire Drive Interface Module

& Ethernet communication Module)

Description of LED functions on the Power Wave 455M

For reference only

G3894 Ethernet Gateway PC Board

LED

#

COLOR FUNCTION

1 Green Indicates Isolated Module Section Supply is ON

2 Green Indicates DeviceNet Supply is ON

3 Green

4 Red

ArcLink Status Indicators (Main System

Slave

ArcLink Connection)

Solid Green only when functional (See software for error codes)

5 Green

6 Red

Reserved For Future Use

7 Green

8 Red

DeviceNet Status Indicators (See software group for coding)

9 Green Indicates Isolated ArcLink Section Supply is ON

10 Green 10Base-T Link Status ON indicates functional ethernet link has been

established

11 Green Receiver Polarity ON indicates proper ethernet signal polarity

12 Green Indicates I/O+5V Supply is ON This is used by differential I/O pair 4

circuitry, J712 pins 1 and 2.

Voltage Sense Board

M19540

J1

99/08/04@11:34:37

J2

99/08/04@11:28:10

VOLTAGE SENSE SELECT

R1

R

3

OCI1 OCI2

R2

C1

D1

L1

TP1

TP2

WIRE DRIVE MODULE

(OPTIONAL K2205)

S1

J87

J86

J85

J84

J83

J82 J81

NO P.C. BOARD MOUNTED LED's

Diode Detail

LED 9

LED 10

LED 5

LED 1

LED 2

LED 3

LED 4

LED6

LED7

LED 8

S1

J11

J10A

J10B

POWER BOARDS

(OPTIONAL K2207)

Description of LED functions on Power-Wave type systems

L11046 DeviceNet Gateway PC Board

LED # COLOR FUNCTION

1 Green Indicates Isolated Module Section Supply is ON

2 Green Indicates DeviceNet Supply is ON

3 Green

4 Red

ArcLink Status Indicators (Main System Slave ArcLink Connection) Solid

Green only when functional (See software for error codes)

5 Green

6 Red

Module Status Indicators (See software group)

7 Green

8 Red

DeviceNet Status Indicators (See software group for coding)

9 Green Indicates Isolated ArcLink Section Supply is ON

19

1

2 3

4

5 6

7

8

O

N

1

2 3

4

5 6

7

8

O

N

'Bank S2 Default'

'Bank S1 Default'

Con

f

iguring the DIP swi

t

ches

on the Devicenet Board

Switch Description

1 Object Instance LSB (see Table 1)

2 Object Instance MSB (see Table 1)

3 Equipment Group 1 Select

4 Equipment Group 2 Select

5 Equipment Group 3 Select

6 Equipment Group 4 Select

7 Reserved for future use

8 Reserved for future use

Switch Description

1

2

3

4

5 DeviceNet Mac ID

6 Default ID=62

7

8

Bank (S1)

Devicenet Board DIP Switch

Bank (S1)

DeviceNet Baud Rate

J5

J6

J7

J8

J9

J4

J3

J2

J1

Troubleshooting the PowerWave

Using the Status LED

GNINAEM

Steady Green

System OK. Power source communicating normally with wire feeder and its

components.

Blinking Green

Occurs during a reset, and indicates the Power Wave is mapping (identifying)

each component in the system. Normal for first 1-10 seconds after power is

turned on, or if the system configuration is changed during operation

Alternating

Green and Red

Non-recoverable system fault. If the PS Status light is flashing any combination

of red and green, errors are present in the Power Wave. Read the error code

before the machine is turned off.

Error Code interpretation through the Status light is detailed in the Service

Manual. Individual code digits are flashed in red with a long pause between

digits. If more than one code is present, the codes will be separated by a green

light.

To clear the error, turn power source off, and back on to reset.

Error codes for the PowerWave

The following is a list of possible error codes that the Power Wave can output via the status light

noitacidnI # edoC rorrE

11 CAN communication bus off.

Probably due to excessive number of communication

errors.

12 User Interface time out error.

UI is no longer responding to the Power Source. The

most likely cause is a fault/bad connection in the

communication leads or control cable.

21 Unprogrammed Weld Mode.

Contact the Service Department for instructions on

reloading the Welding Software.

22 Empty Weld Table.

Contact the Service Department for instructions on

reloading the Welding Software.

23 Weld Table checksum error.

Contact the Service Department for instructions on

reloading the Welding Software.

31 Primary overcurrent error.

Excessive Primary current present. May be related to a

switch board or output rectifier failure.

32 Capacitor “A” under voltage

(Left side facing machine)

33 Capacitor “B” under voltage

(Right side facing machine)

Low voltage on the main capacitors. May be caused by

improper input configuration, or an open/short circuit

in the primary side of the machine.

34 Capacitor “A” over voltage

(Left side facing machine)

35 Capacitor “B” over voltage

(Right side facing machine)

Excess voltage on the main capacitors. May be caused

by improper input configuration, or an open/short

circuit in the primary side of the machine.

36 Thermal error

Indicates over temperature. Usually accompanied by

Thermal LED. Check fan operation. Be sure process

does not exceed duty cycle limit of the machine.

37 Softstart error

Capacitor precharge failed. Usually accompanied by

codes 32-35.

41 Secondary overcurrent error

The secondary (weld) current limit has been exceeded.

When this occurs the machine output will phase back

to 100 amps, typically resulting in a condition refered

to as “noodle welding”

42 Ground lead Current Shutdown

(On K2202-4 machines only)

The K2202-4 has a special circuit installed that

monitors current flowing on the input ground lead.

When current is sensed, the machine will turn the

welding output off. The machine will need to be turned

off for several seconds and then back on to clear this

error.

43 Capacitor delta error

The maximum voltage difference between the main

capacitors has been exceeded. May be accompanied by

errors 32-35.

49 Single phase error

Indicates machine is running on single phase input

power. Usually caused by the loss of the middle leg

(L2).

Other

Error codes that contain three or four digits are defined

as fatal errors. These codes generally indicate internal

errors on the PS Control Board. If cycling the input

power on the machine does not clear the error, try

reloading the operating system. If this fails, replace the

control board.