9

less than 0.07% carbon, the marten-

site is not very hard and the main

hardening is obtained from the aging

(precipitation) reaction. Examples of

this group are 17-4PH, 15-5PH and

PH13-8Mo. Nominal compositions

of precipitation hardening stainless

steels are listed in Table IV.

The semiaustenitic stainless steels

will not transform to martensite when

cooled from the austenitizing temper-

ature because the martensite

transformation temperature is below

room temperature. These steels

must be given a conditioning

treatment which consists of heating

in the range of 1350 to 1750°F (732

to 954°C) to precipitate carbon

and/or alloy elements as carbides or

intermetallic compounds. This

removes alloy elements from solution,

thereby destabilizing the austenite,

which raises the martensite

transformation temperature so that a

martensite structure will be obtained

on cooling to room temperature.

Aging the steel between 850 and

1100°F (454 to 593°C) will stress

relieve and temper the martensite to

increase toughness, ductility, hard-

ness and corrosion resistance.

Examples of this group are 17-7PH,

PH 15-7 Mo and AM 350.

The austenitic precipitation hardening

stainless steels remain austenitic after

quenching from the solutioning

temperature even after substantial

amounts of cold work. They are

hardened only by the aging reaction.

This would include solution treating

between 1800 and 2050°F (982 to

1121°C), oil or water quenching and

aging at 1300 to 1350°F (704 to

732°C) for up to 24 hours.

Examples of these steels include

A286 and 17-10P.

If maximum strength is required in

martensitic and semiaustenitic pre-

cipitation hardening stainless steels,

matching or nearly matching filler

metal should be used and the com-

ponent, before welding, should be in

the annealed or solution annealed

condition. Often, Type 630 filler

metal, which is nearly identical with

17-4PH base metal, is used for

martensitic and semiaustenitic PH

stainlesses. After welding, a

complete solution heat treatment

plus an aging treatment is preferred.

If the post weld solution treatment is

not feasible, the components should

be solution treated before welding

then aged after welding. Thick

sections of highly restrained parts

are sometimes welded in the

overaged condition. These would

require a full heat treatment after

welding to attain maximum strength.

The austenitic precipitation hardening

stainless steels are the most difficult

to weld because of hot cracking.

Welding should preferably be done

with the parts in the solution treated

condition, under minimum restraint

and with minimum heat input. Nickel

base alloy filler metals of the NiCrFe

type or conventional austenitic stain-

less steel type are often preferred.

3.5

DUPLEX

STAINLESS STEELS

Duplex Ferritic – Austenitic

Stainless Steels

Duplex stainless steels solidify as

100% ferrite, but about half of the

ferrite transforms to austenite during

cooling through temperatures above

approx. 1900°F (1040°C). This

behavior is accomplished by

increasing Cr and decreasing Ni as

compared to austenitic grades.

Nitrogen is deliberately added to

speed up the rate of austenite

formation during cooling. Duplex

stainless steels are ferromagnetic.

They combine higher strength than

austenitic stainless steels with

fabrication properties similar to

austenitics, and with resistance to

chloride stress corrosion cracking of

ferritic stainless steels. The most

common grade is 2205 (UNS

S32205), consisting of 22%Cr, 5%Ni,

3%Mo and 0.15%N.

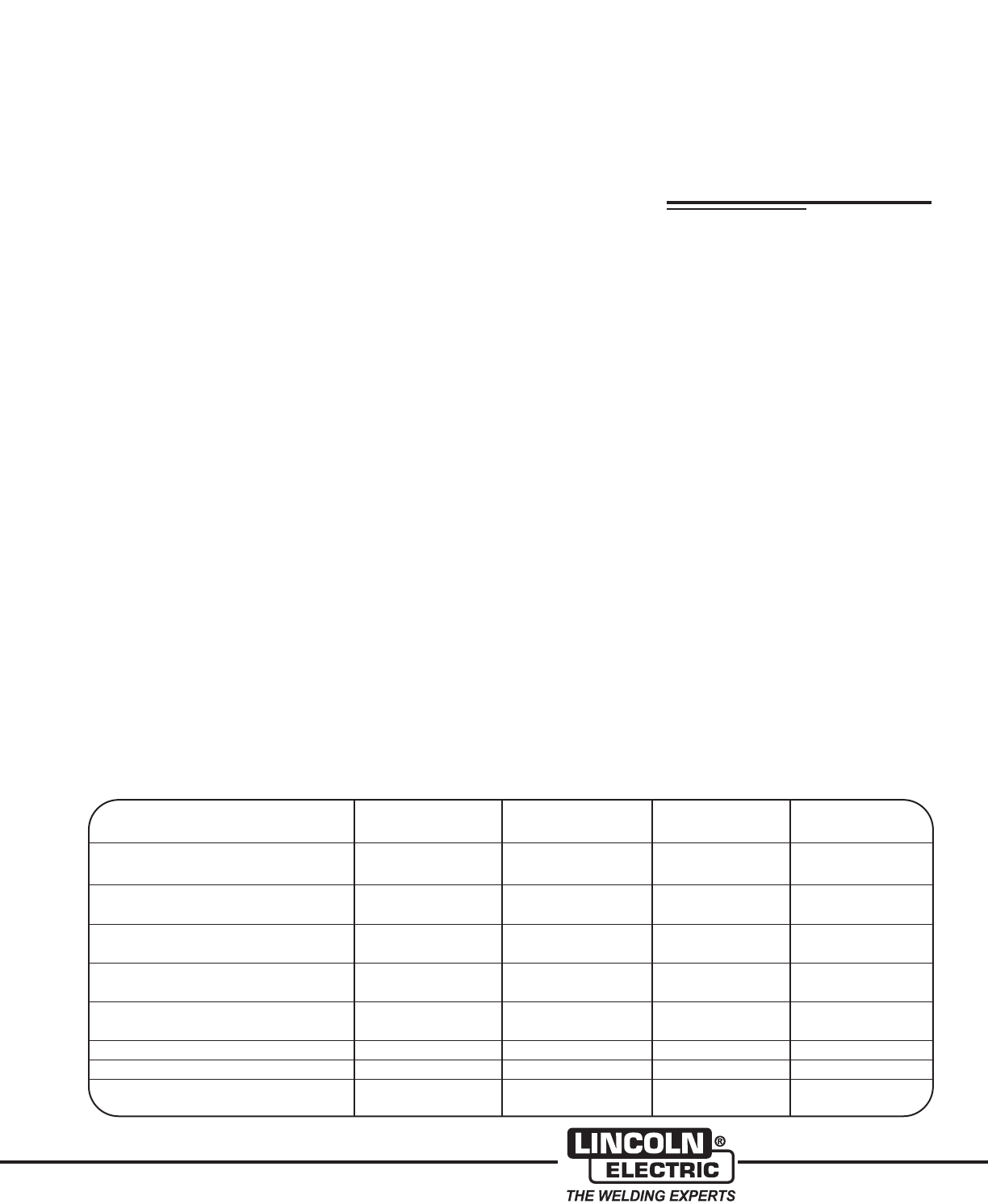

Austenitic Ferritic Martensitic Precipitation

Property Types Types Types Hardening Types

Elastic Modulus; 10

6

psi 28.3 29.0 29.0 29.0

GPa 195 200 200 200

Density; lb./in.

3

0.29 0.28 0.28 0.28

g/cm

3

8.0 7.8 7.8 7.8

Coeff. of Therm. Expansion: µin./in. °F 9.2 5.8 5.7 6.0

µm/m °C 16.6 10.4 10.3 10.8

Thermal. Conduct.; Btu/hrft. °F 9.1 14.5 14.0 12.9

w/mk 15.7 25.1 24.2 22.3

Specific Heat; Btu/lb. °F 0.12 0.11 0.11 0.11

J/k °K 500 460 460 460

Electrical Resistivity, µΩcm 74 61 61 80

Magnetic Permeability 1.02 600-1,100 700-1000 95

Melting Range °F 2,500-2,650 2,600-2,790 2,600-2,790 2,560-2,625

°C 1,375-1,450 1,425-1,530 1,425-1,530 1,400-1,440

TABLE V — Physical Properties of Groups of Stainless Steels