19

protective paper, soap used for leak

testing, etc.

3. Stainless steels cannot be flame

cut with a torch. Acceptable results

are achieved with an arc plasma

cutter.

4. Be particularly careful to avoid zinc

contamination. Do not use brushes

or tools previously used on

galvanized steel.

5. Use only stainless steel wire

brushes, and use these brushes only

on stainless steel.

The decision on the form of filler

metal to be used will depend upon

several factors. These include the

available forms of the filler material

needed, the available welding

equipment, the dimensions of the

weldment and number of pieces to

be welded.

9.1

SHIELDED METAL

ARC WELDING

Coated electrodes are available in

most stainless compositions in a

range of sizes and these can be

used to weld joints in thicknesses

from 0.05 inch to several inches.

Slag from each pass must be

completely removed before

depositing the next pass to avoid

porosity and slag entrapment.

Welding equipment for stick

electrode welding is the lowest cost

but deposition rates are lowest of all

the consumable electrode

processes.

If it has been decided to perform the

welding with stick electrodes, a

further decision must be made

regarding the electrode coating.

When lime (-15), titania (-16), and

silica-titania (-17) type coatings are

available for a particular type

electrode, the decision will be based

mainly on the position of welding.

Lime-coated electrodes operate on

DC only. They are recommended

for:

1. Vertical and overhead welding and

all position applications such as

pipe. The light slag wets rapidly

for good wash-in and no

undercutting.

2. Root passes on heavy plate. The

full throat section of the slightly

con vex beads help prevent

cracking.

3. Fully austenitic stainless steels

such as types 330, 320.

Titania-coated electrodes operate on

AC or DC, but always use DC when

available. They are recommended

for:

1. All applications when most of the

welding is in the flat position.

2. Vertical up and overhead welding

when lime-coated electrodes are

not available.

Silica-titania coated electrodes

operate also on AC or DC, but DC is

usually preferred. They are

recommended for:

1. Flat and horizontal position

welding when minimum cleanup

is desired.

2. Vertical up welding when a wide

weave can be used.

3. Overhead welding.

Coated electrodes should be treated

and stored as low hydrogen

electrodes. They should not be

exposed to damp air, and once a

sealed container is opened, the

electrodes should be used or stored

in a holding oven at between 200

and 300°F (93 and 149°C). If the

electrodes are exposed to moist air,

they can be dried by baking as

recommended by the manufacturer.

This baking tem perature usually is

between 500 and 600°F (260 and

316°C), but can be as high as 800°F

(427°C). The electrode manufacturer

should be consulted for specific

recommendations.

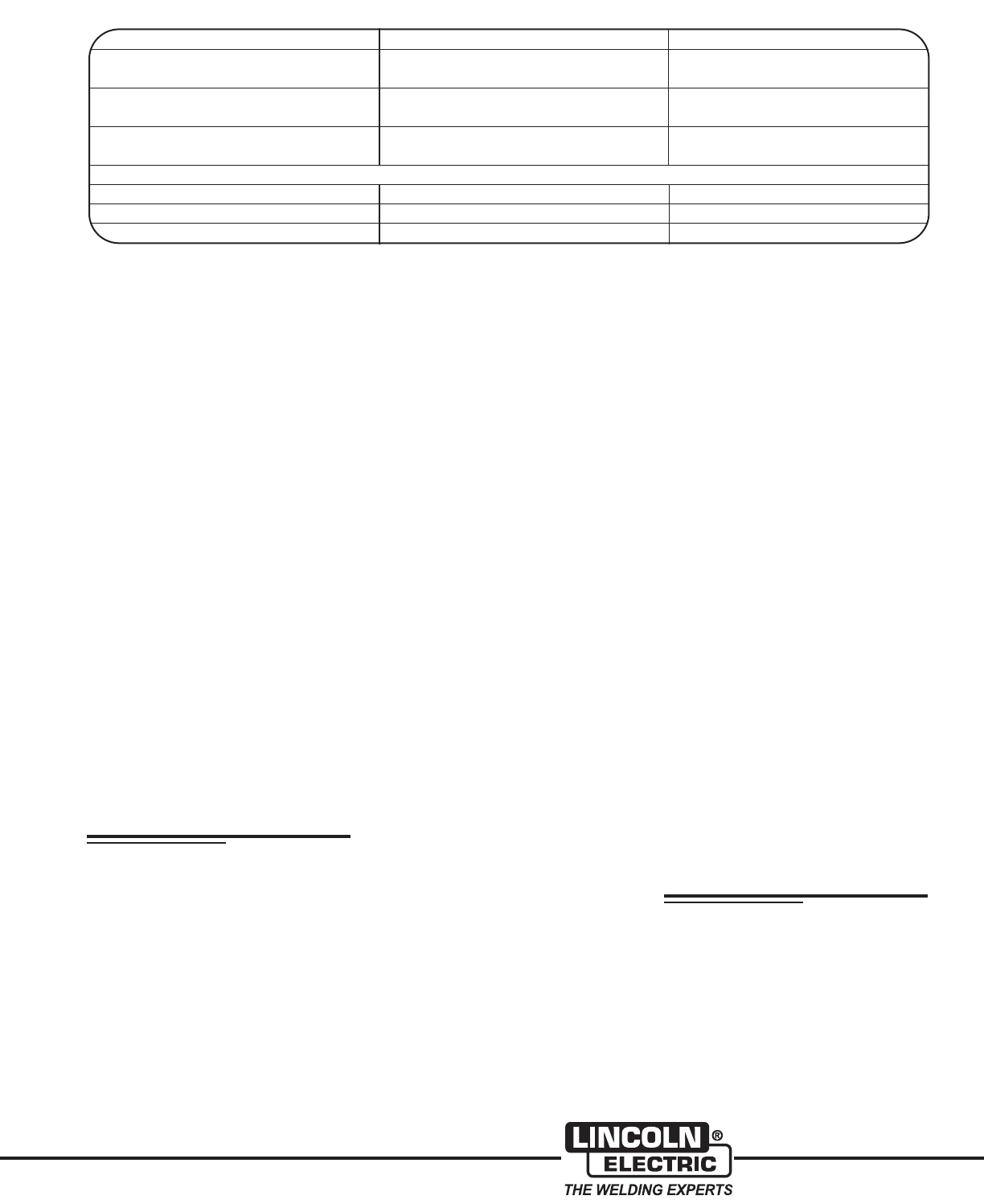

The sizes and forms of coated

electrodes and also solid and cored

wire, which are normally available for

welding stainless steels, are listed in

Table XV

..

9.2

SUBMERGED

ARC WELDING

Submerged arc welding (SAW) can

be employed to join thick sections,

usually greater than 0.5 inch, of most

of the austenitic stainless steels. For

austenitic stainlesses in which ferrite

is not possible in the weld metal

(types 310 or 330, for example),

submerged arc welding is usually

best avoided due to hot cracking

Form Diameter, in. Diameter, mm,

Electrode in coils, with or 0.045, 1/16, 5/64, 3/32, 7/64 1.2, 1.6, 2.0, 2.4, 2.8

without support 1/8, 5/32, 3/16, 1/4 3.2, 4.0, 4.8, 6.4

Electrode wound on standard 0.030, 0.035, 0.045, 1/16 0.8, 0.9, 1.2, 1.6

12-in. O.D. spools 5/64, 3/32, 7/64 2.0, 2.4, 2.8

Electrodes wound on lightweight 0.020, 0.025, 0.030 0.5, 0.6, 0.8

1-1/2 and 2-1/2 lb., 4-in O.D. spools 0.035, 0.045 0.9, 1.2

Coated Electrodes

9 in. length (230 mm) 1/16, 5/64, 3/32 1.6, 2.0, 2.4

12 in. length (305 mm) 3/32 2.4

14 in. length (350 mm) 1/8, 5/32, 3/16, 1/4 3.2, 4.0, 4.8, 6.4

TABLE XV — Standard Sizes for Stainless Electrodes