17

for these alloys, especially if high

strength weld metal is not required

because the lower strength filler can

stretch on cooling and minimize the

stress on the crack sensitive heat

affected zone of the base metal.

Nickel base and conventional

austenitic stainless steels can also be

used to weld the other precipitation

hardening stainless steels where full

base material strength is not

required.

Coated electrodes can be used for

welding martensitic and

semiaustenitic stainless steels such

as 17-4PH, AM350 and AM355

because these alloys do not contain

titanium or aluminum which would

be lost in the shielded metal arc.

Welds can be made in all positions

with this process. Electrodes must

be dry and stored and handled in

the same manner as used for other

stainless steel and low hydrogen

electrodes as described previously.

Type AMS 5827B (17-4PH)

electrodes can be used to weld 17-7

PH steel, and reasonable heat treat -

ment response can be obtained if

the weld deposit is highly diluted

with base metal.

Welding conditions suitable for

conventional stainless steels are

generally applicable for joining the

PH types. A short arc length should

be used to minimize oxidation, loss of

chromium, and nitrogen pickup.

Lining

Mild steel process and storage

equipment is sometimes lined with

stainless steel for corrosion

resistance. At least three different

methods are used:

1. Large formed stainless steel

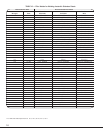

Base Stainless Steel Recommended Filler Metal

Coated Solid, Metal Flux Core

Wrought Cast Electrode Core Wire Wire

405 E410NiMo, E430 ER410NiMo, ER430 E410NiMoTX-X

409 ER409, AM363, EC409 E409TX-X

429 ER409Cb

430 CB-30 E430 ER430 E430TX-X

430F E430 ER430 E430TX-X

430FSe E430 ER430 E430TX-X

434 ER434

442 E442, E446 ER442

444 E316L ER316L

446 CC-50 E446 ER446

26-1 ER26-1

From AWS Filler Metal Specifications: A5.4, A5.9, A5.22

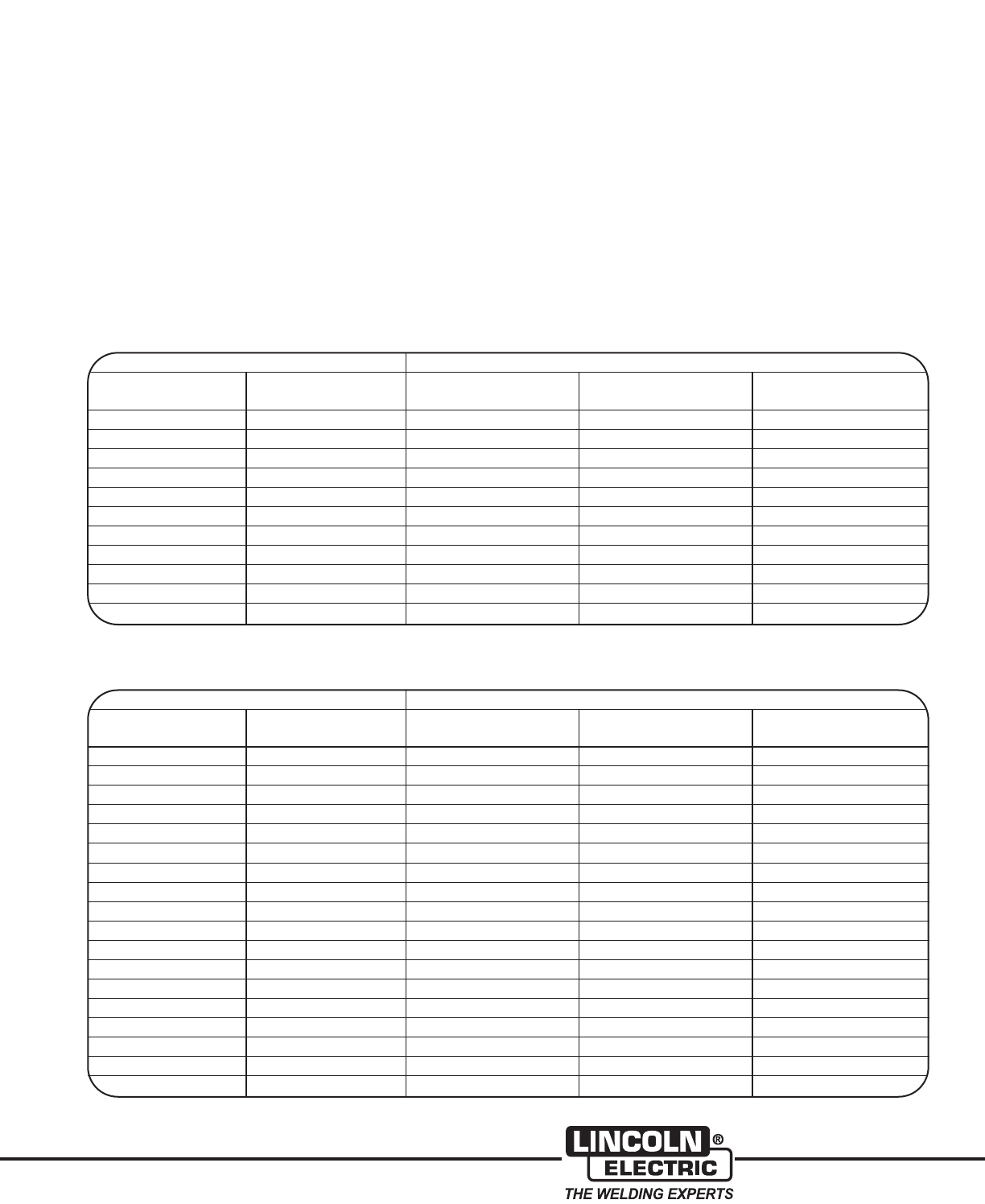

Base Stainless Steel Recommended Filler Metal

Coated Solid, Metal Flux Core

Wrought Cast Electrode Core Wire Wire

403 E410 ER410 E410TX-X

410 CA-15 E410, E410NiMo ER410, ER410NiMo E410T, E410NiMoTX-X

410S E410NiMo ER410NiMo E410NiMoTX-X

414 E410 ER410 E410TX-X

416 E410 ER312, ER410

416Se ER312

416PlusX ER312

420 CA-90 E410, E430 ER420, ER410 E410TX-X

420F ER312

431 CB-30 E410, E430 ER410 E410TX-X

440A a

440B a

440C a

CA-6NM E410NiMo ER410NiMo E410NiMoTX-X

CA-15 E430 ER430 E430TX-X

2205 E2209 ER2209

2304 E2209 ER2209

255 E2553 ER2553

a = Welding not recommended. From AWS Filler Metal Specifications: A5.4, A5.9, A5.22

TABLE XII — Filler Metals for Welding Ferritic Stainless Steels

TABLE XIII — Filler Metals for Welding Martensitic and Duplex Stainless Steels