P 5/10

[3] DISASSEMBLY/ASSEMBLY

Repair

[3] -3. Motor Section

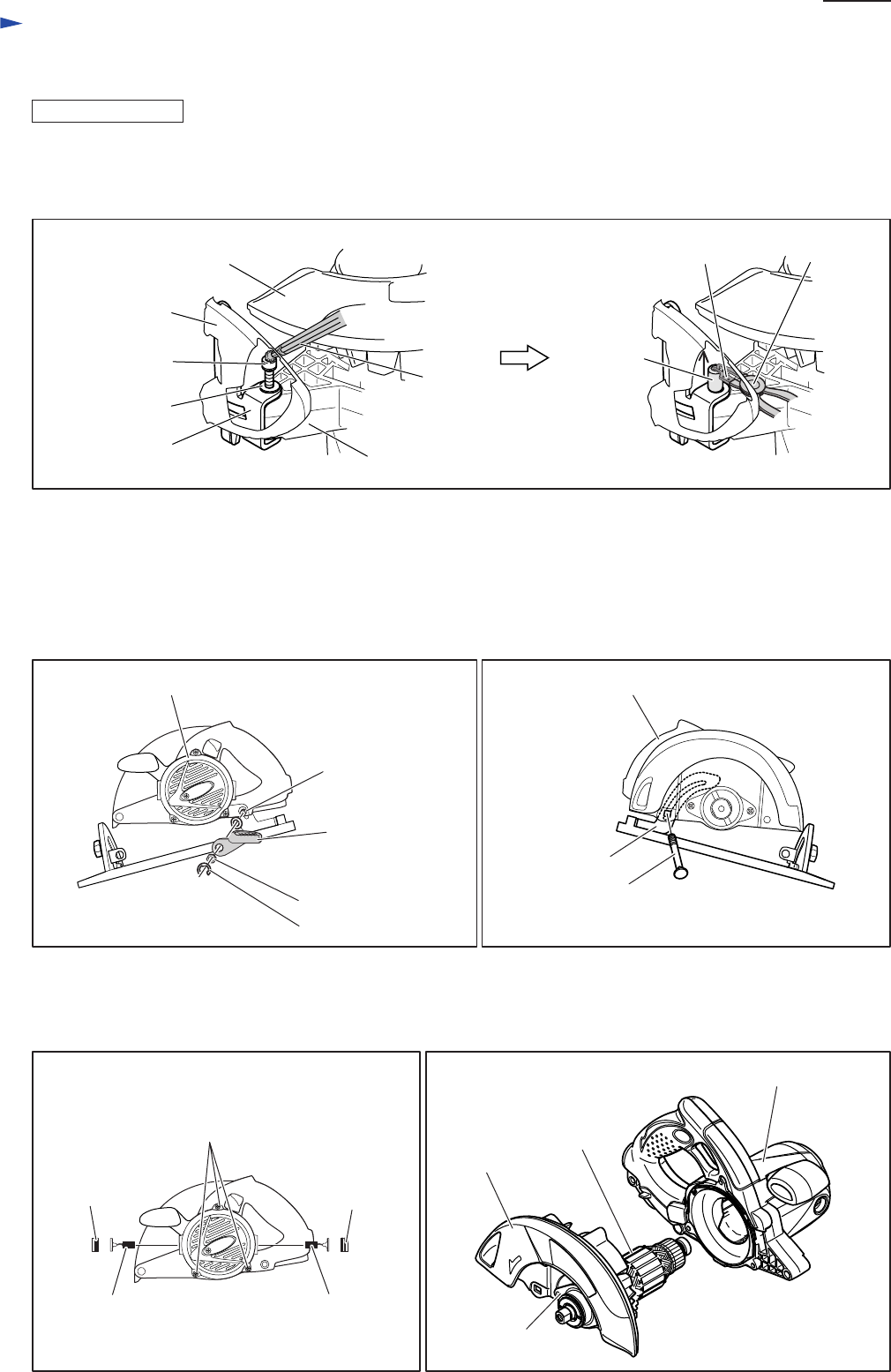

After removing Safety cover, disassemble Motor section as described below;

1) Remove Hex socket head bolt M5x40 using 1R229, then remove Flat washer 5 from Angular guide. (left in Fig. 11)

2) Remove Sleeve 6 using 1R004 and 1R008. (right in Fig. 11)

DISASSEMBLING

Lever 56

(the one used for

cut depth setting)

Bow stop ring E-12

Hex nut M8-13

Cap square neck

bolt M8x90

Depth guide

3) Loosen Hex nut M8x13 halfway with Lever 56; leave the nut on the threads of Cap square neck bolt M8x90

in this step. (Fig. 12)

4) Remove Bow stop ring E-12 with slotted screwdriver. (Refer to Fig. 6 on page 3.)

5) Remove Lever 56 (the one used for cut depth setting), Hex nut M8-13 and Flat washer 8 from Cap square neck bolt

M8x90. (Fig. 12)

6) Pull off cap square neck bolt M8x90. Motor section can be separated from Depth guide and Base complete. (Fig. 13)

7) Remove Brush holder caps and Carbon brushes, then remove three M5x45 Pan head screws. (Fig. 14)

8) Motor housing section can now be separated from Blade case, and electrical parts in Motor housing section can be

replaced. (Fig. 15)

Motor section viewed from Rear cover side

1R008

Sleeve 6

1R004

Cap square neck

bolt M8x90

Armature

Blade case

Motor housing section

Pan head screw M5x45 (3 pcs)

Motor section viewed from Blade case side

Fig. 11

Fig. 12 Fig. 13

Fig. 14 Fig. 15

Carbon brush Carbon brush

Brush

holder cap

Brush

holder cap

Bearing box

Flat washer 5

Hex socket head

bolt M5x40

Angular guide

1R229

Angular plate

of Base complete

Motor housing

Blade case