. A complete Parts List is available on-line at www.MillerWelds.com

OM-225 311 Page 13

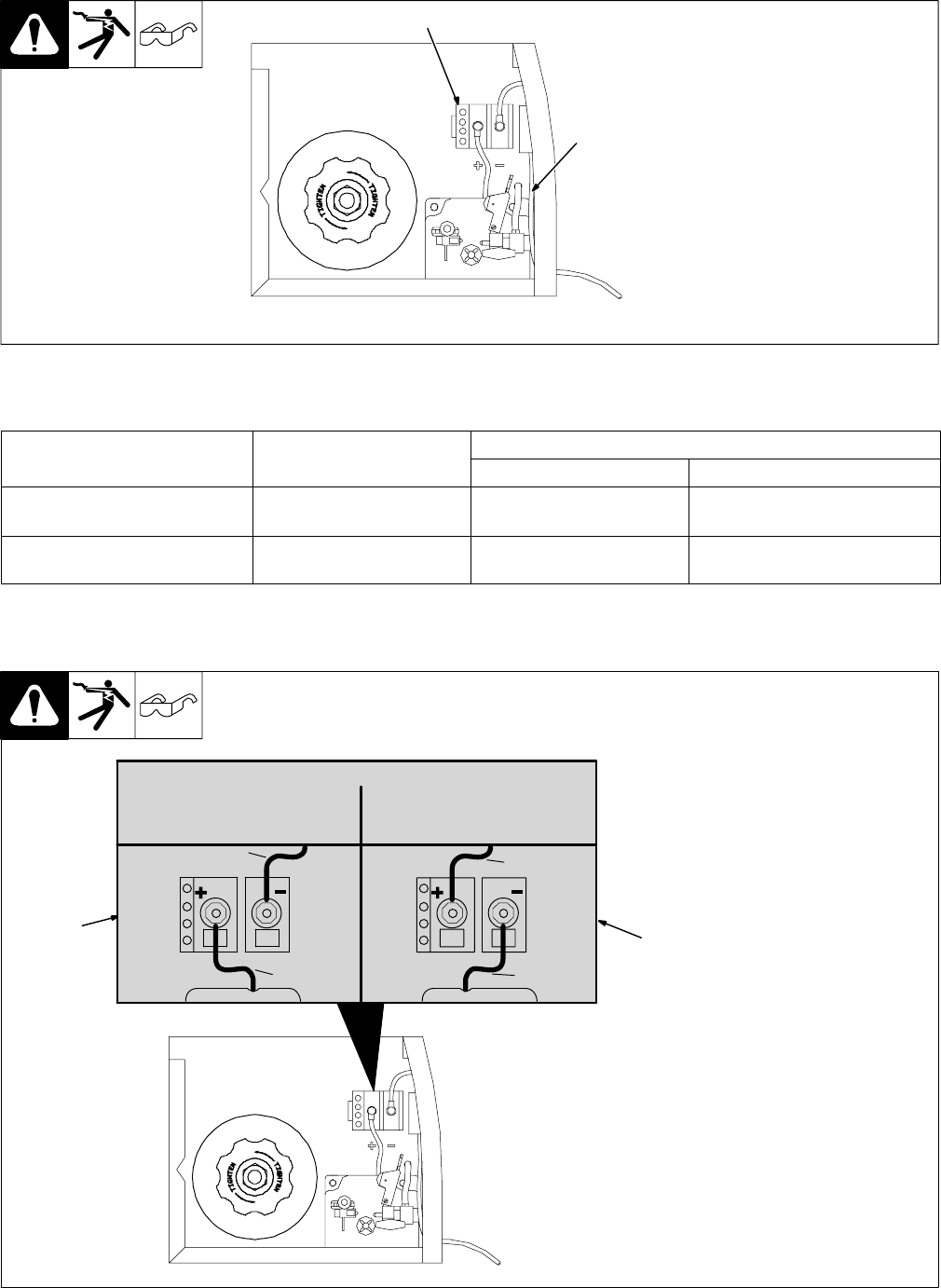

4-3. Work Cable Routing Inside Unit

Ref. 802 982-A

1 Work Cable

2 Output Terminal Block

Insert work cable through opening

in front panel and route along back

of front panel to output terminal

block.

Close door.

2

1

4-4. Process/Polarity Table

Process

Polarity

Cable Connections

Process

Polarity

Cable To Gun Cable To Work

GMAW − Solid wire with shield-

ing gas

DCEP − Reverse polarity Connect to positive (+) out-

put terminal

Connect to negative (−) output

terminal

FCAW − Self-shielding wire −

no shielding gas

DCEN − Straight Polarity Connect to negative (−)

output terminal

Connect to positive (+) output

terminal

4-5. Changing Polarity

1 Lead Connections For Direct

Current Electrode Positive

(DCEP)

2 Lead Connections For Direct

Current Electrode Negative

(DCEN)

Always read and follow wire

manufacturer’s recommended

polarity, and see Section 4-4.

Close door.

1

Ref. 203 501 / Ref. 802 982-

2

CHANGING POLARITY

DCEP

Electrode POSITIVE

FOR SOLID WIRE

DCEN

Electrode Negative

Flux Core Wire

WorkClamp

Lead

WireDrive

Lead

WorkClamp

Lead

WireDrive

Lead

CHANGING POLARITY

DCEP

Electrode Positive

FOR SOLID WIRE

DCEN

Electrode Negative

Flux Core Wire

WorkClamp

Lead

WireDrive

Lead

WorkClamp

Lead

WireDrive

Lead

. Connection hardware must be tightened with proper tools. Do not

just hand tighten hardware. A loose electrical connection will cause

poor weld performance and excessive heating at the terminal block.