. A complete Parts List is available on-line at www.MillerWelds.com

OM-225 311 Page 37

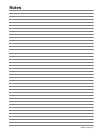

6-4. Changing Drive Roll Or Wire Inlet Guide

1 Inlet Wire Guide

Remove guide by pressing on

barbed area or cutting off one end

near housing and pulling it out of

hole. Push new guide into hole from

rear until it snaps in place.

2 Drive Roll

The drive roll consists of two differ-

ent sized grooves. The stamped

markings on the end surface of the

drive roll refers to the groove on the

opposite side of the drive roll. The

groove closest to the motor shaft is

the proper groove to thread (see

Section 4-11).

3 Retaining Pin

To secure drive roll, locate open slot

and push drive roll completely over

retaining pin, then rotate drive roll

1/4 turn to closed slot.

2

1

3

802 984

.024 Groove.030/.035 Groove

Stamped .024

Stamped .030/.035

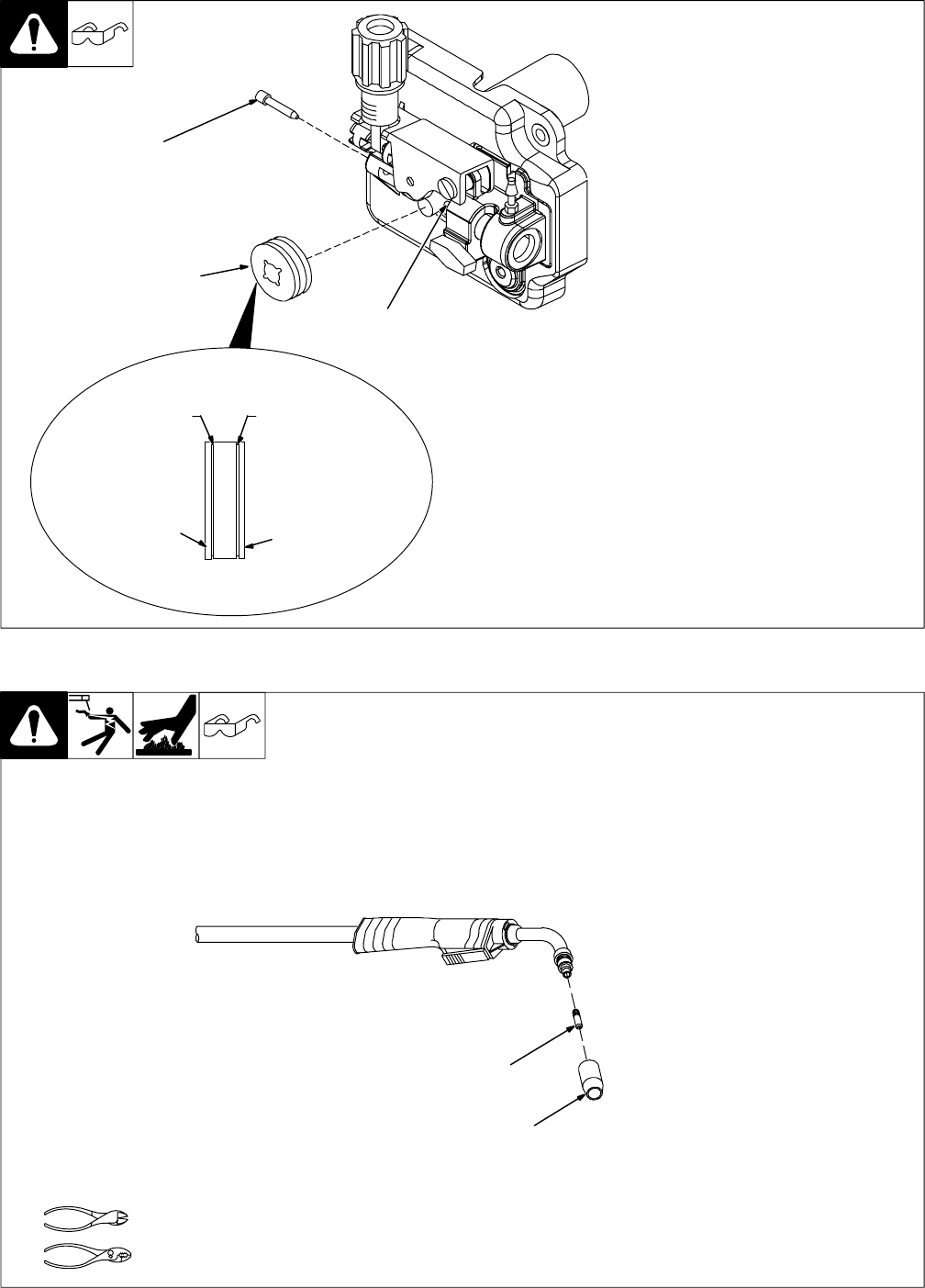

6-5. Replacing Gun Contact Tip

Ref. 802 399-A

Y Turn Off power before

replacing contact tip.

1 Nozzle

2 Contact Tip

Cut off welding wire at contact tip.

Remove nozzle.

Remove contact tip and install new

contact tip. Reinstall nozzle.

Tools Needed:

1

2