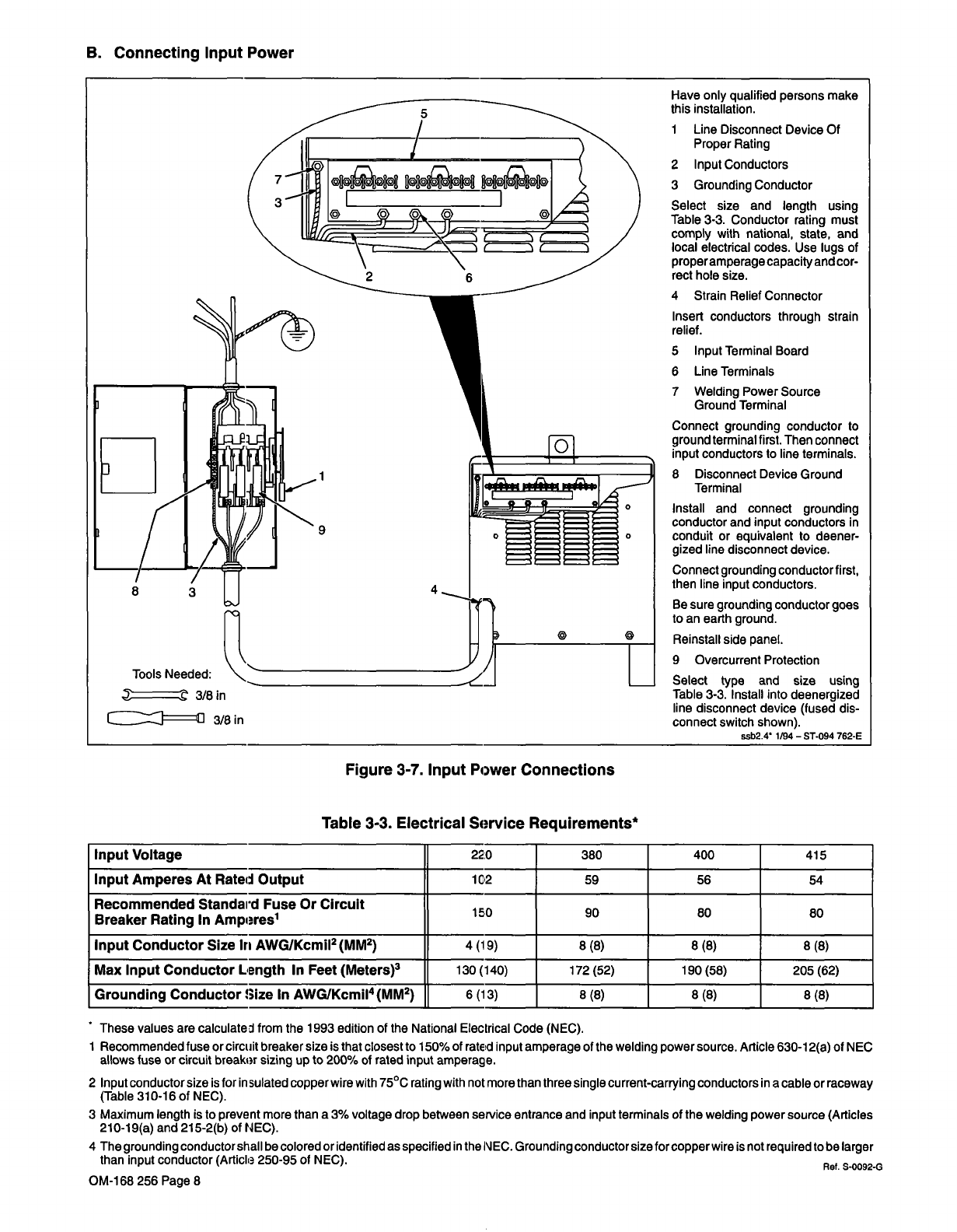

B.

Connecting

Input

Power

Figure

3-7.

Input

Power

Connections

Table

3-3.

Electrical

Service

Requirements*

Input

Voltage

220

380

400

415

Input

Amperes

At

Rated

Output

1C2

59

56

54

Recommended

Standard

Fuse

Or

Circuit

Breaker

Rating

In

Amperes1

lEO

90

80

80

Input

Conductor

Size

In

AWGIKcmII2

(MM2)

4

(19)

8

(8)

8

(8)

8

(8)

Max

Input

Conductor

Length

In

Feet

(Meters)3

130(140)

172

(52)

190(58)

205

(62)

Grounding

Conductor

Size

In

AWGIKcmiI4

(MM2)

6

(13)

8

(8)

8

(8)

8

(8)

These

values

are

calculated

from

the

1993

edition

of

the

National

Electrical

Code

(NEC).

1

Recommended

fuse

or

circuit

breaker

size

is

that

closest

to

150%

of

ratEd

input

amperage

of

the

welding

power

source.

Article

630-12(a)

of

NEC

allows

fuse

or

circuit

breaker

sizing

up

to

200!.

of

rated

input

amperage.

2

Input

conductor

size

is

for

insulated

copper

wire

with

75C

rating

with

not

more

than

three

single

current-carrying

conductors

in

a

cable

or

raceway

(Table

31

0-16

of

NEC).

3

Maximum

length

is

to

prevent

more

than

a

3%

voltage

drop

between

service

entrance

and

input

terminals

of

the

welding

power

source

(Articles

210-19(a)

and

215-2(b)

of

NEC).

4

The

grounding

conductorshall

be

colored

or

identified

as

specified

in

the

NEC.

Grounding

conductor

size

forcopperwire

is

not

required

to

be

larger

than

input

conductor

(Article

250-95

of

NEC).

Ref

S-0092-G

OM-168

256

Page

8

Have

only

qualified

persons

make

this

installation.

1

Line

Disconnect

Device

Of

Proper

Rating

2

Input

Conductors

3

Grounding

Conductor

Select

size

and

length

using

Table

3-3.

Conductor

rating

must

comply

with

national,

state,

and

local

electrical

codes.

Use

Iugs

of

properamperage

capacity

and

cor

rect

hole

size.

4

Strain

Relief

Connector

Insert

conductors

through

strain

relief.

5

Input

Terminal

Board

6

Line

Terminals

7

Welding

Power

Source

Ground

Terminal

Connect

grounding

conductor

to

ground

terminal

first.

Then

connect

input

conductors

to

line

terminals.

8

Disconnect

Device

Ground

Terminal

Install

and

connect

grounding

conductor

and

input

conductors

in

conduit

or

equivalent

to

deener

gized

line

disconnect

device.

Connect

grounding

conductor

first,

then

line

input

conductors.

Be

sure

grounding

conductor

goes

to

an

earth

ground.

Reinstall

side

panel.

9

Overcurrent

Protection

Select

type

and

size

using

Table

3-3.

Install

into

deenergized

line

disconnect

device

(fused

dis

connect

switch

shown).

ssb2.4

1/94

5T-094

762-E

Tools

Needed:

~

3/8

in

3/8

in