7-2.

Preparing

TLungsten

1

Tungsten

Electrode

1

2

Balled

End

Ball

end

of

tungsten

before

welding

by

applying

either

an

ac

amperage

slightly

higher

than

what

is

recom

mended

for

a

given

electrode

diam

eter

(see

NO

TAG),

or

a

dc

elec

trode

positive

amperage.

2

Ret.

S.0161

Figure

7-1.

Preparing

Tungsten

For

AC

Oir

DC

Electrode

Positive

(DCEP)

Welding

~AUTION

4

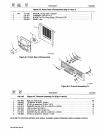

Figure

7-2.

Preparing

Tungsten

For

DC

Electrode

Negative

(DCEN)

Welding

F

LYING

SPARKS

AND

HOT

METAL

can

cause

injury

and

start

fires.

Shapetur~gsten

electrode

only

on

grinderwith

proper

guards

in

a

safe

location

wearing

properface,

hand,

and

body

protection.

Keep

f(ammables

away.

wam2.1

9/91

1

Tungsten

Electrode

2

Tapered

End

Grind

end

of

tungsten

on

fine

grit,

12

hard

abrasive

wheel

before

weld

ing.

Do

not

use

wheel

tor

other

jobs

or

tungsten

can

become

contami

kT-~

nated

causing

lower

weld

quality.

2-1/2

Times

Electrode

Diameter

Ref.

S.0161

1

1

Stable

Arc

i~:::::/~~

2

Flat

Ideal

Tungsten

Preparation

Stable

Arc

Ref.

S.0162

1

1

Arc

Wander

~

2

Point

~

3

Grinding

Wheel

~__,_~

4

Radial

Ground

4

Wrong

Tungsten

Preparation

Wandering

Arc

Ret.

S-0162

Diameter

of

this

flat

detormines

amperage

capacity.

3

Grinding

Wheel

4

Straight

Ground

OM-168

256

Page

21