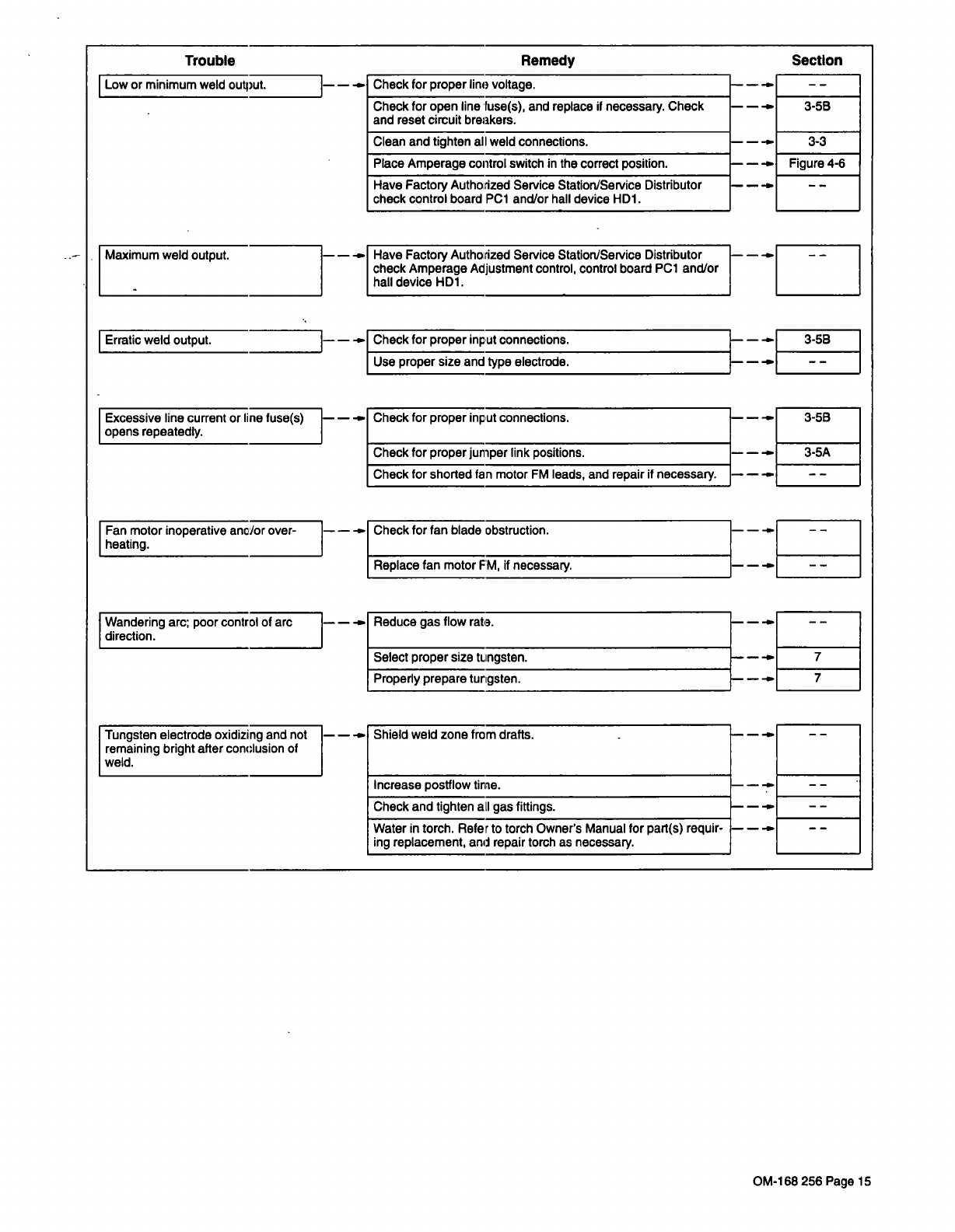

Trouble

Remedy

Section

Low

or

minimum

weld

output.

-~

Check

for

proper

lino

voltage.

-~

Check

for

open

line

ruse(s),

and

replace

if

necessary.

Check

-~

3-58

and

reset

circuit

breakers.

Clean

and

tighten

all

weld

connections.

-~

3-3

Place

Amperage

control

switch

in

the

correct

position.

-~

Figure

4-6

Have

Factory

Authoi~zed

Service

Station/Service

Distributor

-~

check

control

board

PCi

and/or

hall

device

HD1.

Maximum

weld

output.

Have

Factory

Authoi~zed

Service

Station/Service

Distributor

I

-~

check

Amperage

Adjustment

control,

control

board

PCI

and/or

hall

device

HD1.

Erratic

weld

output.

Check

for

proper

input

connections.

H

3-58

Use

proper

size

and

type

electrode.

-~

Excessive

line

current

or

line

fuse(s)

~

-~

Check

for

proper

input

connections.

-~

3-5B

opens

repeatedly.

I

____________________________________________________

_____________

Check

for

proper

juniper

link

positions.

-~

3-5A

Check

for

shorted

fan

motor

FM

leads,

and

repair

if

necessary.

-~

Fan

motor

inoperative

anc/or

over-

Check

for

fan

blade

obstruction.

1

-~

heating.

____________________________________________________

_____________

Replace

fan

motor

FM,

if

necessary.

-~

Wandering

arc;

poor

control

of

arc

Reduce

gas

flow

rate.

-~

direction.

Select

proper

size

tungsten.

-~

7

Properly

prepare

tungsten.

-~

7

i~ngsten

electrode

oxidizing

and

not

-~

Shield

weld

zone

from

drafts.

-~

remaining

bright

after

conclusion

of

weld.

Increase

postflow

time.

-~

Check

and

tighten

all

gas

fittings

-~

Water

in

torch.

Refer

to

torch

Owners

Manual

for

part(s)

requir-

-~

ing

replacement,

and

repair

torch

as

necessary.

OM-168

256

Page

15