5-2.

Overload

Protection

\~

READ

Sectio

SAFETY

n

5

befor

BLOCKS

at

start

of

e

proceeding.

minutes

When

overheated,

thermostat

Let

fan

run

for

Start

welding.

opens,

output

stops,

and

cooling

15

minutes.

fan

keeps

running.

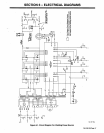

ssblO.1

1194-ST-000

599-H

Figure

5-2.

Overheating

5-3.

Troubleshooting

4~

WARNING

ELECTRIC

SHOCK

can

kill.

MOVING

PARTS

can cause

injury.

Do

not

touch

live

electrical

parts.

Keep

away

from

moving

parts.

Turn

Off

welding

power

source,

and

disconnect

input

power

before

inspecting,

maintaining,

or

servicing.

HOT

PARTS

can

cause

severe

burns.

Allow

cooling

period

before

servicing.

.

Troubleshooting

to

be

performed

only

by

qualified

persons.

swamg.1

2/93

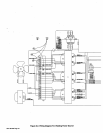

Table

5-1.

Welding

Trouble

-

Trouble

Remedy

Section

No

weld

output;

unit

completely

j.

-~

Place

line

disconnect

switch

in

the

On

position.

inoperative.

-

Check

for

open

line

fuse(s),

and

replace

if

necessary.

Check

and

reset

circuit

breakers.

Check

for

proper

input

connections.

Check

for

proper

jumper

link

positions.

Thermostat

TP1

open.

Allow

a

cooling

period

of

approximately

fifteen

minutes.

Check

push

button

Power

switch

linkage

for

restrictions

or

obstructions.

No

weld

output;

pilot light

PLI

on.

-~

Clean

and

tighten

all

weld

connections.

-~

3-3

Place

Output

(Contactor)

switch

in

the

On

position

or

connect

-~

Figure

4-4

Remote

Contactor

Control

To

RC1.

Check

remote

contactor

control

switch

for

proper

operation

with

-~

an

ohmmeter,

and

replace

if

necessary.

Have

Factory

Authorized

Service

Station/Service

Distributor

-~

check

control

board

PCi.

OM-168

256

Page

14