a

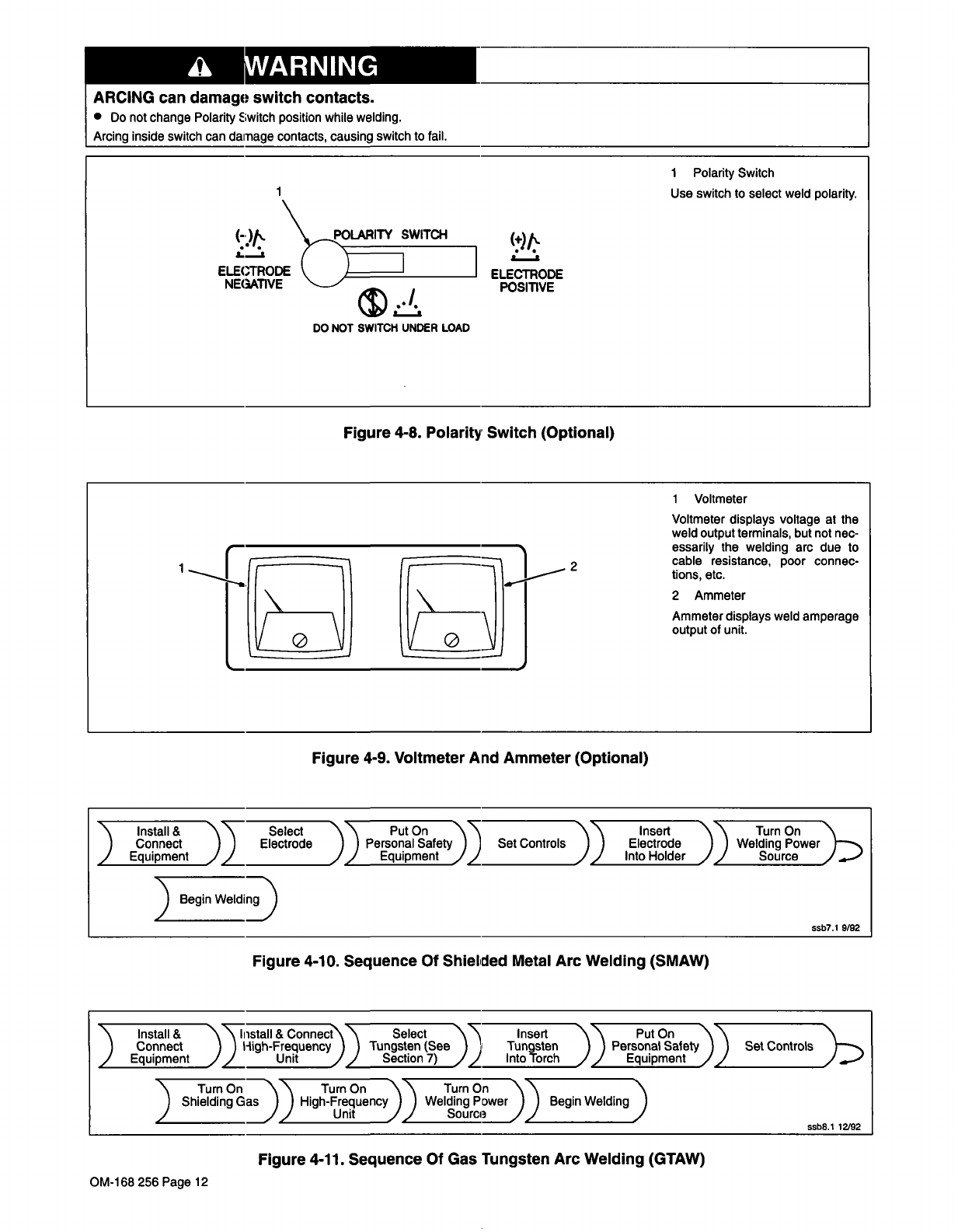

~JVARNING

ARCING

can

damago

switch

contacts.

Do

not

change

Polarity

Switch

position

while

welding.

Arcing

inside

switch

can

damage

contacts,

causing

switch

to

fail.

Li

Figure

4-8.

Polarity

Switch

(Optional)

Figure

4-9.

Voltmeter

And

Ammeter

(Optional)

Figure

4-10.

Sequence

Of

Shielded

Metal

Arc

Welding

(SMAW)

Figure

4-11.

Sequence

Of

Gas

Tungsten

Arc

Welding

(GTAW)

1

Polarity

Switch

1

Use

switch

to

select

weld

polarity.

(-)/%.

~~~OLARITY

SWITCH

(+)/~.

ELECTRODE

_______________

ELECTRODE

NEGATIVE

POSITIVE

DO

NOT

SWITCH

UNDER

LOAD

1

Voltmeter

Voltmeter

displays

voltage

at

the

weld

output

terminals,

but

not

nec

essarily

the

welding

arc

due

to

2

cable

resistance,

poor

connec

tions,

etc.

2

Ammeter

Ammeter

displays

weld

amperage

output

of

unit.

~\\

Insert

\

Install&

Connect

Electrode

Personal

Safety

Set

Controls

)

Electrode

}

Equipment

))I

Equipment

)~

~,J)

Into

Holder

)~we)

Select

))

Put

On

)

Begin

WeldiD

ssb7.1

9/92

Connect

High-Frequency

~

Tungsten

(See

Tungsten

Per

____________

Unit

J)

Section

7)

Into

Torch

))

Equipment

\

Install

&

j)~1stall

&

Connect~~

Select

)~

Insert

Put

On

))I~~~ntrolD.~

sonal

Safety

)

Equipment

____________

________________

______________

________________

On

Turn

On

Turn

O~I~)

Begin

WeIdin~)

)

Shielding

Gas

)

High-Frequen

Welding

Powe

______________

)

Unit

Source

ssb8.1

12/92

OM-168

256

Page

12