Maximum

weld

output.

--~__

Erratic

weld

output.

I-..

-.-~

3-5B

-

-

Excessive

line

current

or

line

fuse(s)

-~

opens

repeatedly.

Check

for

shorted

tan

motor

FM

leads,

and

repair

if

necessary.

-~

3-5B

3-5A

-~

--

Fan

motor

inoperative

and/or

over-

-~

heating.

Replace

fan

motor

FM,

if

necessary.

--

--

-~

--

Wandering

arc;

poor

control

of

arc

-~

direction.

Tungsten

electrode

oxidizing

and

not

-~

remaining

bright

after

conr~lusion

of

weld.

Properly

prepare

tungsten.

Low

or

minimum

weld

output.

Trouble

Remedy

1

-~

Check

for

proper

lina

voltage.

Check

for

open

line

fuse(s),

and

replace

if

necessary.

Check

and

reset

circuit

breakers.

Clean

and

tighten

all

weld

connections.

Place

Amperage

control

switch

in

the

correct

position.

Have

Factory

Authorized

Service

Station/Service

Distributor

check

control

board

PCi

and/or

hall

device

HD1.

---

--~

--~

--~

--~

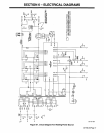

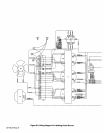

Section

3-5B

3-3

Figure

4-6

Have

Factory

Authorized

Service

Station/Service

Distributor

check

Amperage

Adjustment

control,

control

board

PCi

and/or

hail

device

HD1.

Check

for

proper

input

connections.

Use

proper

size

and

type

electrode.

Check

for

proper

input

connections.

Check

for

proper

jumper

link

positions.

Check

for

fan

blade

obstruction.

Reduce

gas

flow

rata.

Select

proper

size

tungsten.

Shield

weld

zone

from

drafts.

Increase

postf

low

time.

Check

and

tighten

all

gas

fittings.

Water

in

torch.

Refer

to

torch

Owners

Manual

for

part(s)

requir

ing

replacement,

and

repair

torch

as

necessary.

--~

---

--a

OM-168

256

Page

15