OM-216 244 Page 31

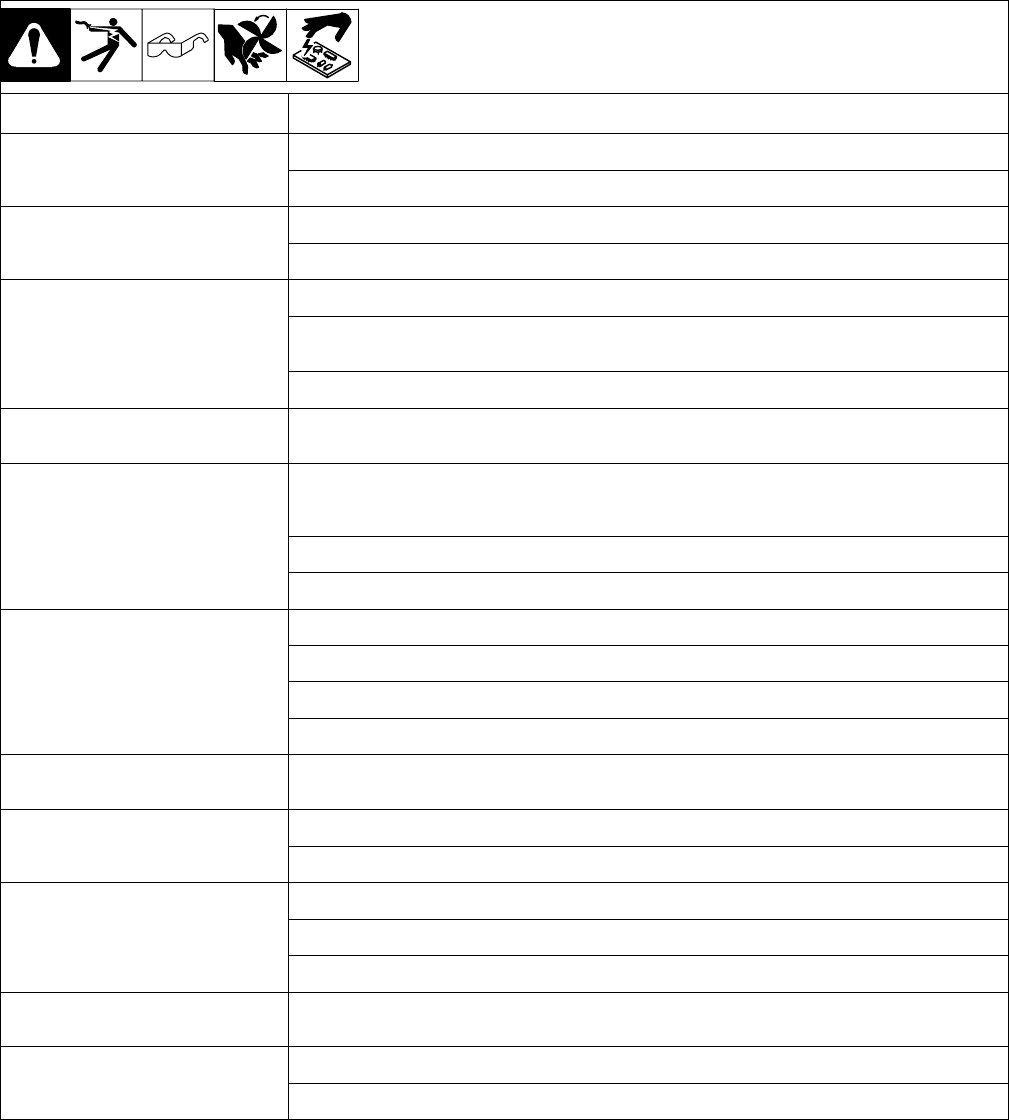

8-6. Troubleshooting - Stud Gun

Trouble Remedy

Hang up - Stud looks like it’s sitting on

a pedestal with an hour glass shape

Check alignment of the foot.

a

pe

d

es

t

a

l

w

ith

an

h

our

g

l

ass

s

h

ape

Service the gun to ensure lift/release actions are functioning properly.

Undercutting or lack of fillet

Too little plunge. Increase amount of stud extending past end of ferrule or spark shield.

Too little weld time or current. Check Section 7 for base line power recommendations.

Splatter or BB’S emitting from the weld

zone

Too much plunge. Decrease amount of stud extending past end of ferrule or spark shield.

zone.

Dampener Required. If you have a dampener the dampener may have worn out and need replace-

ment. See optional equipment in Section 12.

Too much Current or Time. Check Section 7 for base line power recommendations.

Stud breaks off and weld zone looks

”crystalized”

Not enough weld current or time. Check Section 7 for base line power recommendations.

Bubbles in weld fillet

If you are attempting short arc you may not be able to eliminate this condition. To improve this situa-

tion shorten time and increase current. If the results continue to be unsatisfactory then you may need

to add a shielding gas.

Check gas flow/type of shielding gas.

If using flux loaded studs, check to make sure there is a flux load present in the end of the stud.

No lift

Check gun coil connections.

Check for gun coil short or open. There should be 19 ohms of resistance in the gun coil.

Check adjustable core and make sure it is not bottomed out (turned into far clockwise).

Check trigger circuit for opens and shorts.

Short stud and cant get enough to ex-

tend past the ferrule

Adjust the internal stop in the chuck.

Arc Extinguishes, or just get a tiny arc-

but no weld

Too much lift. Review set up procedures in Section 5.

b

u

t

no

we

ld

Check ground path from the power source. All joints must be very tight.

No weld

Broken weld cable.

Broken or bad ground cable/connection.

Check gun lift.

Gun shaft does not move freely when

compressed by hand

Dirt is binding the mechanism. Service gun

Gun spindle is sloppy and has allot of

free play

Front bearing may be worn out or missing. Replace bearing.

f

ree

p

l

ay

Front cover may be loose. Tighten nuts.