18

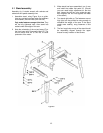

9.4 Switch lockout

The table saw is equipped with a push-button

switch that will accept a safety padlock, as shown

in Figure 20. To safeguard your machine from

unauthorized operation and accidental starting by

young children, the use of a padlock (not included)

is highly recommended. Place the key in a location

that is inaccessible to children and others not

qualified to use the tool.

Figure 20: Switch Lock Out

10.0 Adjustments

10.1 Fence alignment

Before using the Accu-Fence

®

, verify that it is

properly aligned with the blade. Consult the

manual, no. M-2195075Z, that accompanied the

fence.

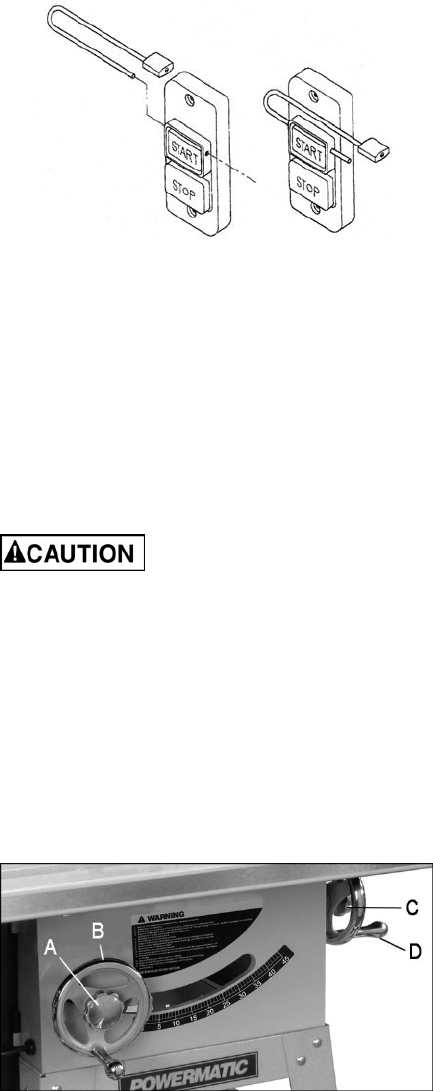

10.2 Blade raising/tilt mechanism

Do not try to force tilting

mechanism past the 45º or 90º stops. This may

cause blade to go out of alignment.

Refer to Figure 21:

To raise or lower blade, loosen lock knob (A) and

turn handwheel (B) on front of saw until desired

height is reached. Tighten lock knob. The blade

should be adjusted about 1/8" above top surface of

material being cut.

To tilt blade, turn lock knob (C) counter-clockwise

to loosen, turn handwheel (D) until desired angle is

obtained, and retighten lock knob (C).

Figure 21

10.3 Miter gauge

Refer to Figure 22.

10.3.1 Setting miter angle

The precision miter gauge has a rack and pinion

adjustment for setting the angle. To operate:

1. Slide miter gauge into one of the slots on table

top.

2. Loosen lock handle (A, Figure 22) by turning

counterclockwise.

3. Pull out spring-loaded knob (C) and rotate

knob until body (B) of miter gauge is at the

desired angle as indicated on the scale.

4. Tighten lock handle (A).

10.3.2 Indent settings

There are indents at the 0º, 30º and 45º right and

left positions. At these settings, release knob (C) to

engage stop rod. Then tighten lock handle (A).

Note: Do not rely solely on the indents for an

accurate setting. After the stop rod engages at the

0º, 30º and 45º positions, make a fine adjustment

with the knob (C) if necessary, setting it against the

scale indicator (G).

10.3.3 Extension plate

The extension plate (D, Figure 22) can be adjusted

by sliding to the right or left or removed entirely.

To adjust, loosen two lock handles (E), position the

extension plate and retighten lock handles. Make

sure end of extension plate is not in the blade’s

path.

NOTE: The lock handles (E) are adjustable. Pull

out on a handle, rotate it to different position, then

release, making sure it seats itself upon the pin.

To remove extension plate, slide it completely off

and remove lock handles (E) and mounting

hardware.

10.3.4 Calibration

1. Place miter gauge in one of the slots on the

table top.

2. Set miter gauge at 90º to blade (0º setting on

the scale) by loosening lock handle (A), then

pulling out spring-loaded knob (C) and turning

the body (B) until 0º is indicated on scale.

3. Measure the accuracy of the gauge against

the slot with a combination square.

If adjustment is necessary:

4. Adjust body (B) until it is perfectly square (90º)

to miter slot.

5. Tighten lock handle (A).

6. Verify that scale indicator (G) reads 0º. If

further adjustment is needed: