26

12.0 Safety devices

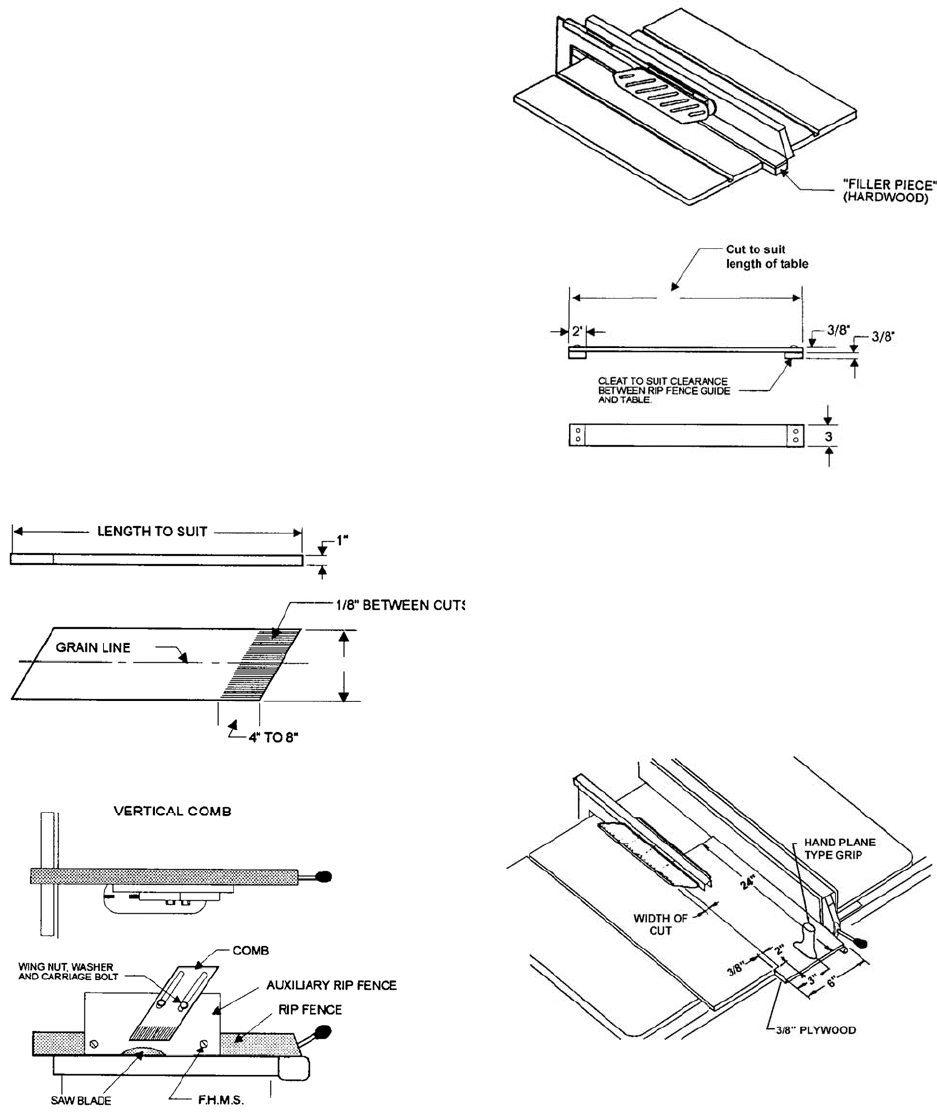

Feather board

Feather boards can be purchased at most tool

stores, or made by the operator to suit particular

applications. The feather board (Figure 44) should

be made of straight grain hardwood approximately

1" thick and 4" to 8" wide depending on the size of

the machine. The length is developed in

accordance with intended use.

Feather boards can be fastened to the table or rip

fence by use of C-clamps. Alternatively, drilled and

tapped holes in the table top allow the use of wing

nuts and washers as a method of clamping. If this

method of fastening is used, provide slots in the

feather board for adjustment. (The illustration

shows a method of attaching and use of the

feather board as a vertical comb. The horizontal

application is essentially the same except that the

attachment is to the table top.)

Figure 44

Filler piece

A filler piece (Figure 45) is necessary for narrow

ripping and permits the blade guard to remain on

the machine. It also provides space for the safe

use of a push stick.

Figure 45 – Filler Piece

Push stick and push block

The use of a push block or push stick provides an

added level of safety for the operator. A push stick

is included with your table saw, but you may wish

to make others personalized for different cutting

procedures. The templates in Figures 46 and 47

offer construction details.

Figure 46 – Push Block Template