21

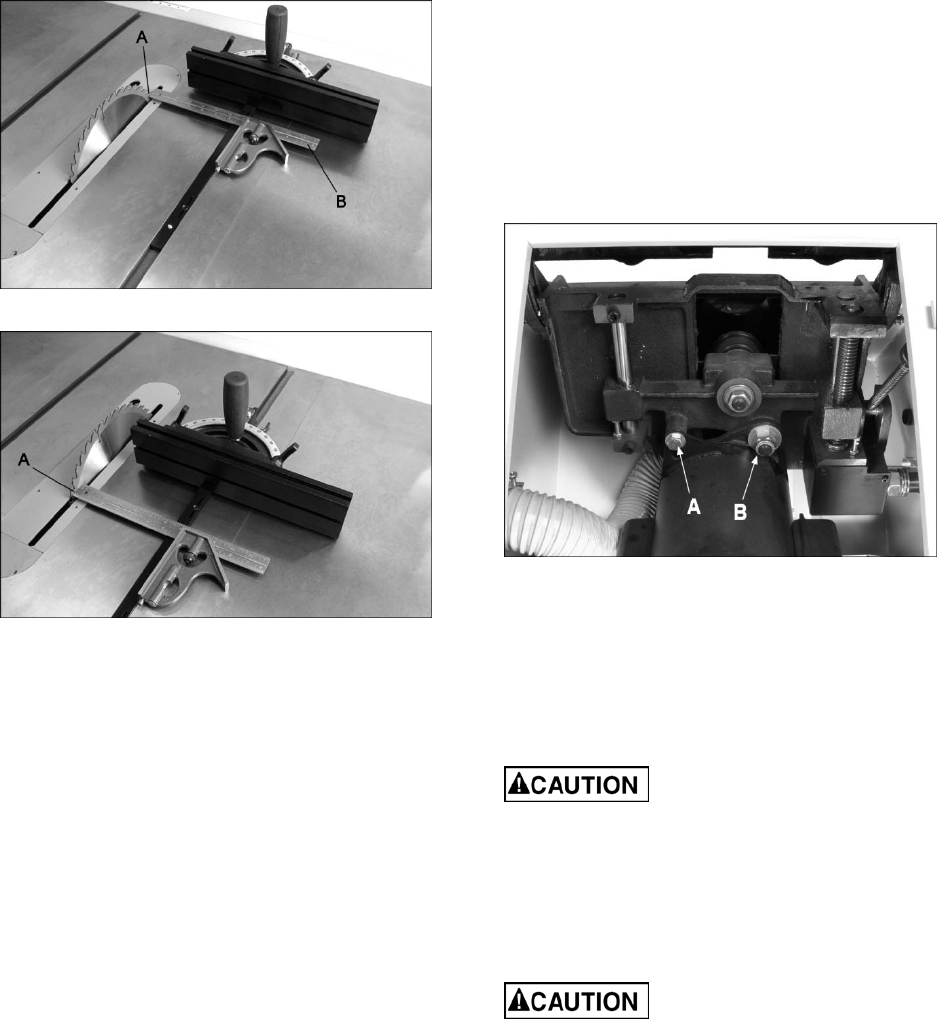

Figure 29

Figure 30

5. Rotate marked tooth (A) so that it is slightly

above table top at the rear and, using the

square as before, verify that the distance to

the blade is the same. See Figure 30. If the

distances are not the same, make a careful

note of the difference.

6. Loosen table screws (item #30, section

16.1.1), and nudge table according to the

distance you noted.

7. Retighten screws firmly.

8. Verify the alignment, angle pointer setting,

fence setting, etc. Make any needed

adjustments.

10.9 Belt tension and replacement

Tension of the drive belt should be inspected after

the first few days of operation, as it may stretch

slightly during initial use; also inspect it periodically

thereafter.

To tighten belt:

1. Disconnect machine from power source.

2. Loosen screw (A, Figure 31) and hex nut (B,

Figure 31).

3. Press down on motor while retightening screw

(A) and hex nut (B).

If belt shows signs of wear, fraying, cracks, etc. it

should be replaced:

1. Loosen screw (A) and hex nut (B) and pivot

motor upward to release tension on belt. If

greater movement is needed, remove screw

(A) and pivot motor further.

2. Replace belt.

3. Reinstall screw (A) and push down on motor to

tension new belt.

4. Tighten screw (A) and hex nut (B).

Figure 31

11.0 Operations

NOTE: If the saw is to be used without the metal

stand provided, care must be taken to provide a

hole in the stand or bench used by the operator to

facilitate removal of sawdust.

If there is any tendency to

slide, walk, or tip over during operation, the

stand or bench MUST be secured to the floor.

Familiarize yourself with the location and operation

of all controls and adjustments and the use of

accessories such as miter gauge and rip fence.

11.1 Start/stop switch

This table saw has a manual

switch. If the power goes out during operation,

push the STOP button. Otherwise, the saw will

start up when power is restored.

11.2 Kickback prevention

Serious injury can result from kickbacks which

occur when a workpiece binds on the saw blade or

binds between the blade and rip fence or other

fixed object. This binding can cause the workpiece

to lift up and be thrown toward the operator.

Listed below are conditions which can cause

kickbacks:

Confining the cutoff piece when

crosscutting or ripping.