22

Resaw Pin

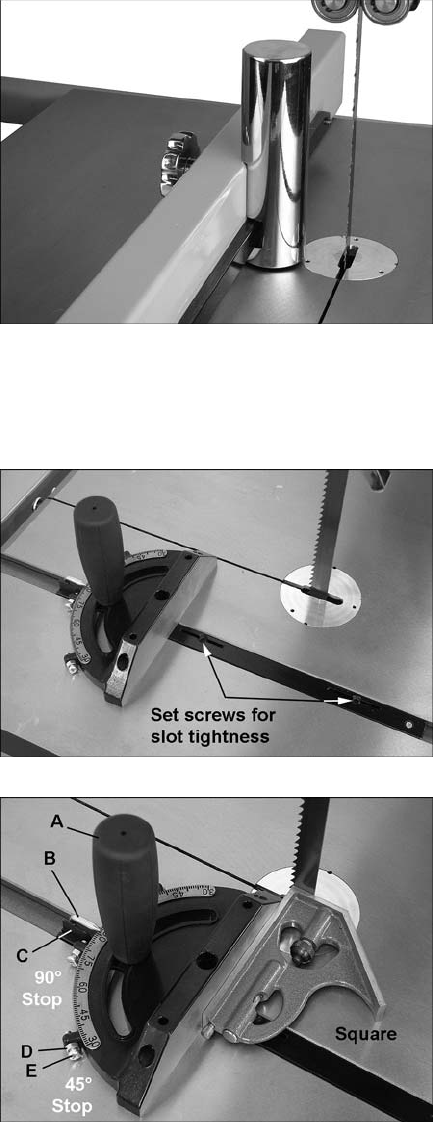

Refer to Figure 35.

A resaw pin is provided with the band saw. It

provides a single contact point while ripping a

workpiece into thinner boards.

Remove the aluminum resaw fence and mount

the resaw pin to the slot in the fence body,

securing it with the knob, as shown. The resaw

pin is usually positioned so that its center is

approximately even with the front edge of the

blade.

See under “Operation” for further information on

using the resaw pin.

Miter Gauge

Refer to Figures 36 and 37.

A miter gauge is provided for crosscutting

operations. Install the miter gauge by sliding the

end of the miter gauge bar into the table’s T-slot.

The miter gauge should fit snugly within the

miter slot while still sliding easily. The bar of the

miter gauge has two slots, each with a set screw

(Figure 36). Rotate one or both of these set

screws with a 5/32” (4mm) hex wrench as

needed to eliminate any play between the miter

gauge bar and miter slot.

If the table/miter slot is square to the blade (see

“Setting Table Parallel to Blade”), the miter

gauge will also be square to the blade. Before

operating, however, the 90° setting of the miter

gauge should be checked in relation to the

blade, as follows.

1. Place a square against the miter gauge

face, and against the flat of the blade, as

shown. (Place the square against the flat of

the blade, not the teeth which are set wider

than the blade body). A wide blade is

preferred for this procedure.

2. Flip the 90° stop plate (C) out of the way,

and loosen the handle (A). Shift the miter

gauge body until it is flush with the square,

then re-tighten the handle (A).

3. Flip the stop plate (C) back down, and

loosen the 90° stop hex nut and adjust the

screw until it contacts the 90° stop plate.

4. Re-tighten hex nut.

5. Loosen the set screw at the base of the

pointer, and shift the pointer so that it lines

up with the 90° mark on the scale.

6. Re-tighten set screw.

Figure 35

Figure 36

Figure 37