28

Maintenance

Before doing maintenance

on the machine, disconnect it from the

electrical supply by pulling out the plug or

switching off the main switch! Failure to

comply may cause serious injury.

Clean the band saw regularly to remove any

resinous deposits and sawdust.

Keep the miter slot, and the guide bearings,

clean and free of resin.

Keep the blade clean and sharp. Check it

periodically for cracks or other signs of wear.

The drive belt should be checked periodically. If

it looks worn, frayed, glazed or otherwise

damaged, replace it.

Remove any deposits from the band wheels to

avoid vibration and potential blade breakage.

Vacuum or blow out dust from inside the

cabinet. (Use proper dust mask equipment).

The table surface must be kept clean and free of

rust for best results. If rust appears, you can use

a mixture of household ammonia, good

commercial detergent and #000 steel wool.

Alternatively, commercial rust removers can be

found at many hardware stores.

Apply a light coat of paste wax to the table.

There are also products in aerosol form

available in major hardware stores and supply

catalogs. Whatever method is chosen, the

coating should protect the metal and provide a

smooth surface, without staining workpieces.

If the power cord is worn, cut, or damaged in

any way, have it replaced immediately.

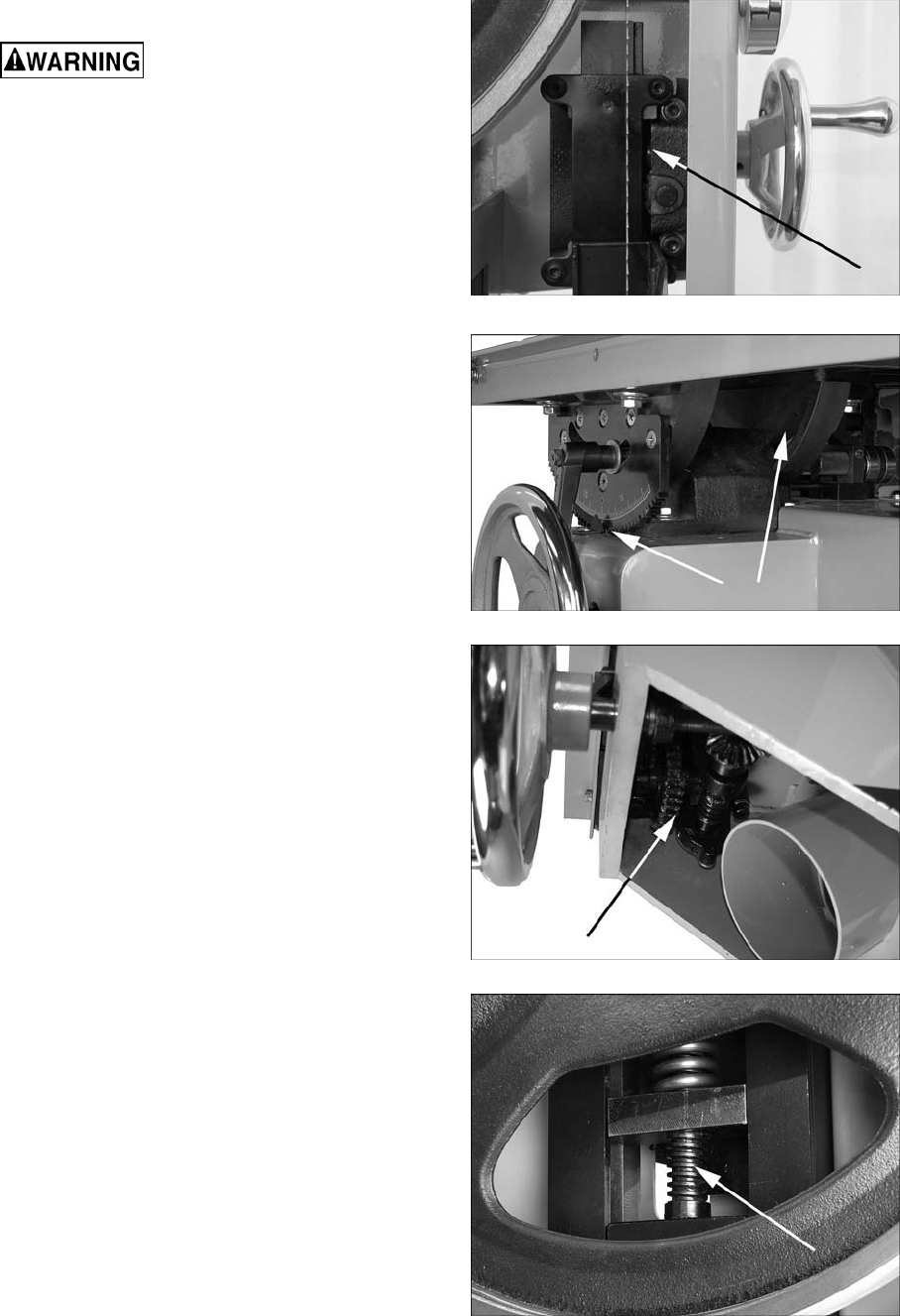

Lubrication Points:

Periodically apply a light, non-hardening grease

to the rack and pinion system of the guide post

(Figure 49).

Grease the sliding surfaces of the table

trunnions (Figure 50). Also grease the contact

area of the trunnion scale and handwheel gear

(Figure 50) and the other gears connected to the

handwheel (Figure 51).

Grease the blade tension screw (Figure 52).

Oil any pins, shafts, and joints. Do not get oil on

the pulleys or belts.

Note: Bearings on the band saw are sealed for

life and do not require lubrication.

Figure 49

Figure 50

Figure 51

Figure 52