27

Arcs and Circles

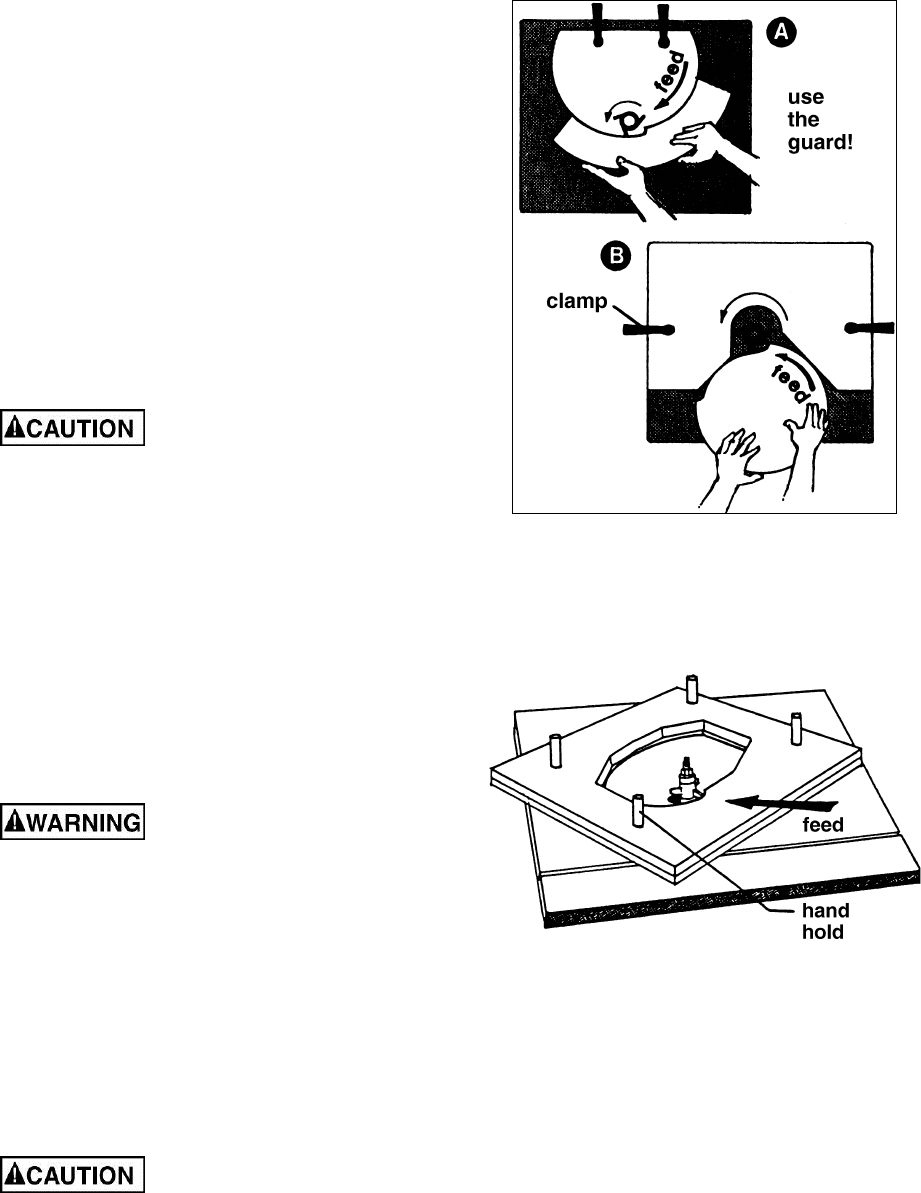

Large circular and arc-shaped stock can be

shaped as described in Contour Edge Shaping on

page 24. However, smaller sized stock requires the

use of special shaping jigs similar to those shown

in Figure 47.

With the entire fence assembly removed, carefully

position the jig for desired depth-of-cut and

securely clamp to the table.

It is important with the arc and circle shapes that

the workpiece, prior to being shaped, must be

roughly cut to the desired size and curve of the

finished piece. Make sure that the jig curve

matches exactly the workpiece curve. At all times

keep the workpiece firmly in contact with the jig

while the cutter is cutting the stock.

Never perform this type

operation without a ring guard, safety collar or

similar safety device over the cutterhead.

Enclosed Edge Shaping

An enclosed workpiece edge is shaped in the

same manner as an outside contoured edge

except that a starting pin is not required as shown

in Figure 48.

Note: If the whole edge is to be shaped, the

operator must use a pattern.

Position the workpiece on the table before starting

the motor. The operator must do the entire shaping

cut by pushing (feeding) the workpiece into the

cutter(s).

Enclosed edge shaping is

extremely dangerous. The operator must be

aware at all times of the direction of feed. Never

perform this type operation without a ring

guard, safety collar or similar safety device

over the cutterhead.

With a firm grip, ease the edge into the cutter(s)

until stopped by the collar as shown in Figure 48.

Continue to push straight in while feeding and

turning the workpiece at the same time until the cut

is finished. Turn off the motor and do not remove

workpiece until the cutters have completely

stopped.

Never perform enclosed edge

shaping if there is less than two inches of

workpiece material all around the opening.

Never perform enclosed edge shaping if the

workpiece opening is smaller, in any direction,

than twice the diameter of the cutter(s).

Figure 47

Figure 48