33

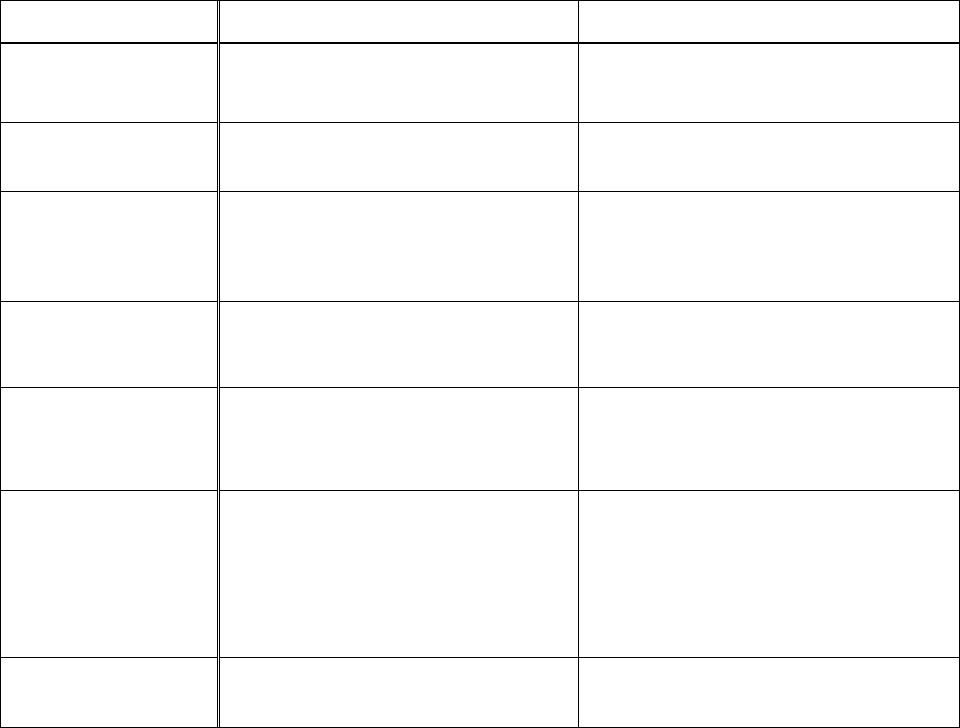

Trouble Possible Cause Remedy

Raised areas on

shaped edge.

1. Variation of pressure holding work

against cutter.

1. Hold work firmly against table and

fence. Use hold-downs and push

sticks.

Work pulled from

hand.

1. Feeding in wrong direction. 1. Always feed work against the

rotation of the cutterhead.

Depth of cut not

uniform.

1. Fence misalignment.

2. Side pressure not uniform.

1. Align outfeed fence.

2. Use hold-downs; keep constant

pressure against fence and use

push sticks.

Work burns.

1. Cutting too deep on one pass.

2. Forcing work.

1. On hardwoods take light cuts; attain

full depth with several passes.

2. Feed work slowly and steadily.

Cut height not

uniform.

1. Variation in pressure holding work

to table.

1. Keep pressure uniform throughout

pass. Use hold-downs. Make pass

slowly and steadily. Keep work

under cutter whenever possible.

Cuts not smooth.

1. Wrong R.P.M.

2. Feed too fast.

3. Working against the grain.

4. Cutting too deep on one pass.

1. Use faster speed.

2. Slow feed speed.

3. Work with the grain whenever

possible.

4. Take several passes on very deep

cuts.

Spindle does not

raise freely.

1. Shaper dust and dirt in raising

mechanism.

1. Brush or blow out loose dust and

dirt.

Optional Accessories

1791205 1" Spindle

1791207 1/4" Collet

1791208 1/2" Collet