43

Lubrication

Ball Bearings

All the motor bearings in this tool are lubri-

cated with a sufficient amount of high

grade lubricant for the life of the unit,

therefore, no further lubrication is

required.

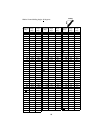

Infrequent Lubrication as Required

1. Apply automotive type oil directly on

slide tubes. It will be picked up and dis-

persed by built in felt wicks.

2.Apply a light oil or a pressurized light

spray oil to the arm pivot shaft.

3. Apply a light oil or a pressurized light

spray oil to the torsion spring as

shown.

4. Apply a light oil or a pressurized light

spray oil to the lower guard spacer,

roller and cover plate as shown.

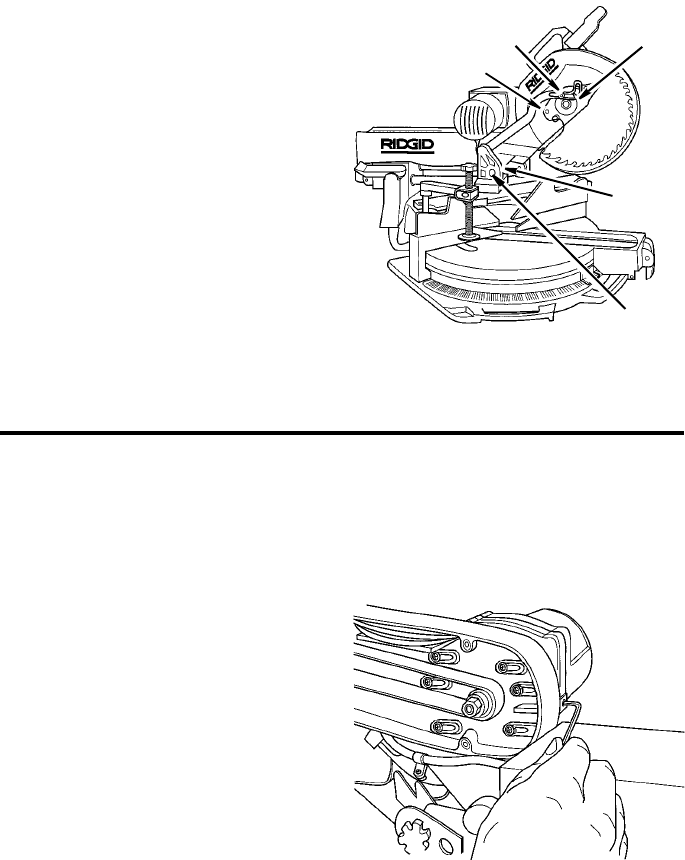

Motor Belt Tension

The motor belt tension was properly

adjusted at the factory. However, to check

the belt tension:

1. Use a Phillips screwdriver to remove

the five screws holding the belt cover

and remove the cover.

2. To check the belt tension squeeze the

belt. Using light pressure the belt

should deflect approximately 1/4".

3. To adjust the tension:

a. Use a Phillips screwdriver to loosen

(but do not remove) the six motor

mount screws.

b. To increase the belt tension turn the

adjusting socket head set screw

clockwise. To decrease the tension

turn the adjusting set screw counter-

clockwise.

NOTE: Excessive belt tension will

cause the motor to fail prematurely.

c. Securely tighten the six motor mount

screws.

4. Replace the belt cover.

Roller

Spacer

Cover

Torsion

Spring

(Inside)

Arm

Pivot Shaft

Plate