16

Assembly (continued)

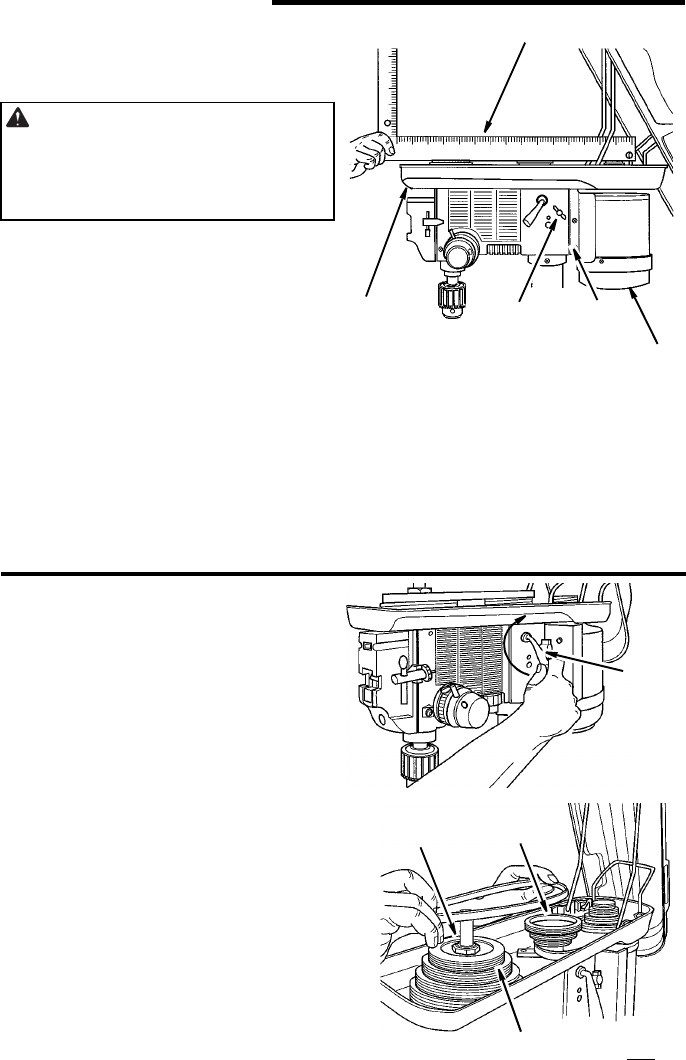

Pulley Alignment and Speed

Adjustment

Checking Pulley(s) Alignment

WARNING: To reduce the risk of

injury due to accidental starting

always turn drill press off and

remove switch key before making

belt adjustments.

Pulley alignment is set at the factory and

should not require further adjustment.

1. Place the idler pulley from loose parts

bag into the head as shown. Place

belts from loose parts bag on pulleys

following speed adjustment instruc-

tions below.

2. Place a straightedge such as a piece of

wood, metal, or framing square across

the top of pulleys.

3. The top of all three pulleys should touch

the straightedge.

4. If not:

Straightedge

Belt

Tension

Lock

Handle

Motor

Mount

Nuts

Motor

Lower

Belt

Guard

• Loosen the motor mount nuts.

• Move the motor until the pulleys are

in line.

• Retighten the motor mount nuts.

NOTE: To avoid rattles or other noise,

motor frame must not touch lower belt

guard.

Speed Adjustment

1. Release belt tension lock handles

located on each side of drill press head

by turning them counterclockwise.

2. Loosen belt tension by turning belt ten-

sion handle clockwise.

3. Use speed chart inside belt guard to

choose speed for drilling operation.

Install belts in correct position for desired

speed. The longer of the two belts is

always positioned between the spin-

dle pulley and idler pulley.

IMPORTANT: Visually check to make sure

the four ribs on the belt are placed into the

four pulley grooves.

Belt

Tension

Handle

Idler

Spindle

Pulley

Pulley

Properly aligned belt should not

touch the stepped surface on

the pulley