32

Tilting Table

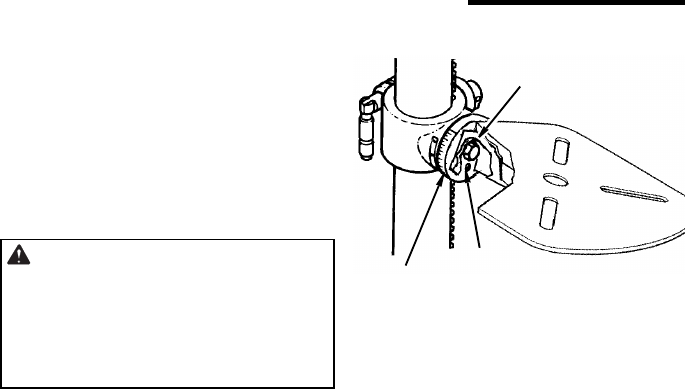

To use the table in a bevel (tilted) position,

loosen the set screw under table bevel

lock with hex “L” wrench. Loosen bevel

lock bolt with the 24mm flat wrench

(included).

Tilt table to desired angle by reading

bevel scale. Retighten bevel lock and set

screw.

WARNING: To reduce the risk of

injury from spinning work or tool

breakage, always clamp workpiece

and backup material securely to

table before operating drill press

with the table tilted.

To return table to original position: Loosen

set screw and bevel lock, tilt table back to

0° on bevel scale and retighten set screw,

then tighten bevel lock.

Hole Location

Make a dent in the workpiece where you

want the hole, using a center punch or a

sharp nail.

Before turning the switch on, bring the drill

down to the workpiece lining it up with the

hole location.

Feeding

Pull down on the feed handles with only

enough effort to allow the drill to cut.

Feeding too slowly might cause the drill to

burn. Feeding too rapidly might stop the

motor, cause the belt or drill to slip, tear

the workpiece loose or break the drill bit.

When drilling metal, it may be necessary

to lubricate the tip of the drill with cutting

oil or motor oil to prevent burning of the

drill tip.

Bevel Lock

Set Screw

Bevel Scale

Basic Drill Press Operation (continued)