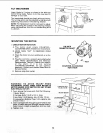

5. Fromamongthelooseparts,find thefollowing

hardware:

4 CarriageBolts,5/16- 18×3/4in,long

4 Flatwashers17/64x 3/4x 1/16

4 Hex.Nuts,5/16- 18(approx,dia.of ho_e5/16

in.)

4 Lockwashers.5/16in. ExternalType

(approx.alia.of hole5/t6 n.)

6. #lacemotoronMOTORMOUNT... insertbolts

throughholesinMOUNTthenthroughthemotor.

Install Iockwashers.and hex. nuts. Do not

tighten.

7. PositionMOTORBASEon MOTORMOUNTso

theedgesofthe MOTORBASEandtheMOTOR

MOUNTare even. Tighten all 4 Hex. nuts

securely.

THESE TWO EDGES_EVEN __

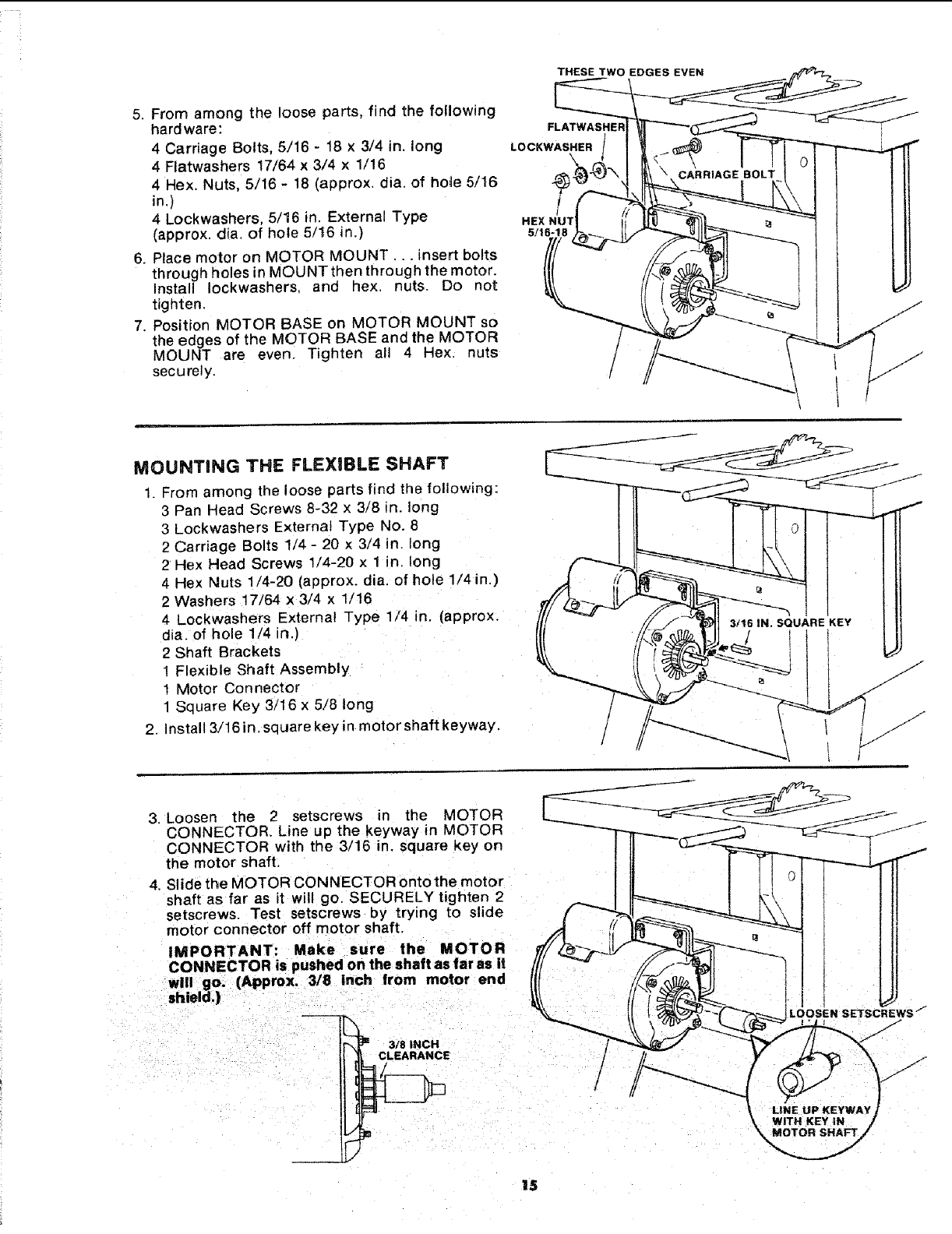

MOUNTING THE FLEXIBLE SHAFT

1. From among the loose parts find the following:

3 Pan Head Screws 8-32 x 3/8 in. long

3 Lockwashers Externat Type No. 8

2 Carriage Bolts 1/4 - 20 x 3/4 in. long

2 Hex Head Screws 1/4-20 × 1 in. long

4 Hex Nuts 1/4-20 (approx. dia. of hole 1/4 in.)

2 Washers 17/64 x 3/4 x 1/16

4 Lockwashers External Type 1/4 in. (approx.

alia. of hole 1/4 in.)

2 Shaft Brackets

1 Flexible Shaft Assembly

1 Motor Connector

1 Square Key 3/16 x 5/8 long

2. Install 3/16 in. square key in motor shaft keyway.

Loose.t.o2setscrews.he.OTO.

3. CONNECTOR. Line up the keyway in MOTOR _-_-_-nr_.___ j i_f

CONNECTOR with the 3/16 in. square key on i tl £z"'I--"_---_----_ i J

t.e o,or Ill

4. SlidetheMOTOROONNECTORontothemotor II! I t! °l ! I1t

shaft as far as it will go. SECURELY tighten 2 __ I I_-------_ I k-\ I { I It

setscrews. Test setscrews by trying to slide f _'_l..=..__----------_t \\ I I I II

motor connector off motor shaft. /_ _/ _-"_ _ t !li

CONNIECTOR is puslted on the shaft as far as it /1/ ""_,_¢ _ _f-_! --71i I!l

_._,,So.€,pp,o=_8,.o,,,oretoo,o,..,

IL_ = 3/8 INCH

_5