-26-

For Machines Mfg. Since 8/11

Model SB1001 8K

™

Lathe

OPERATION

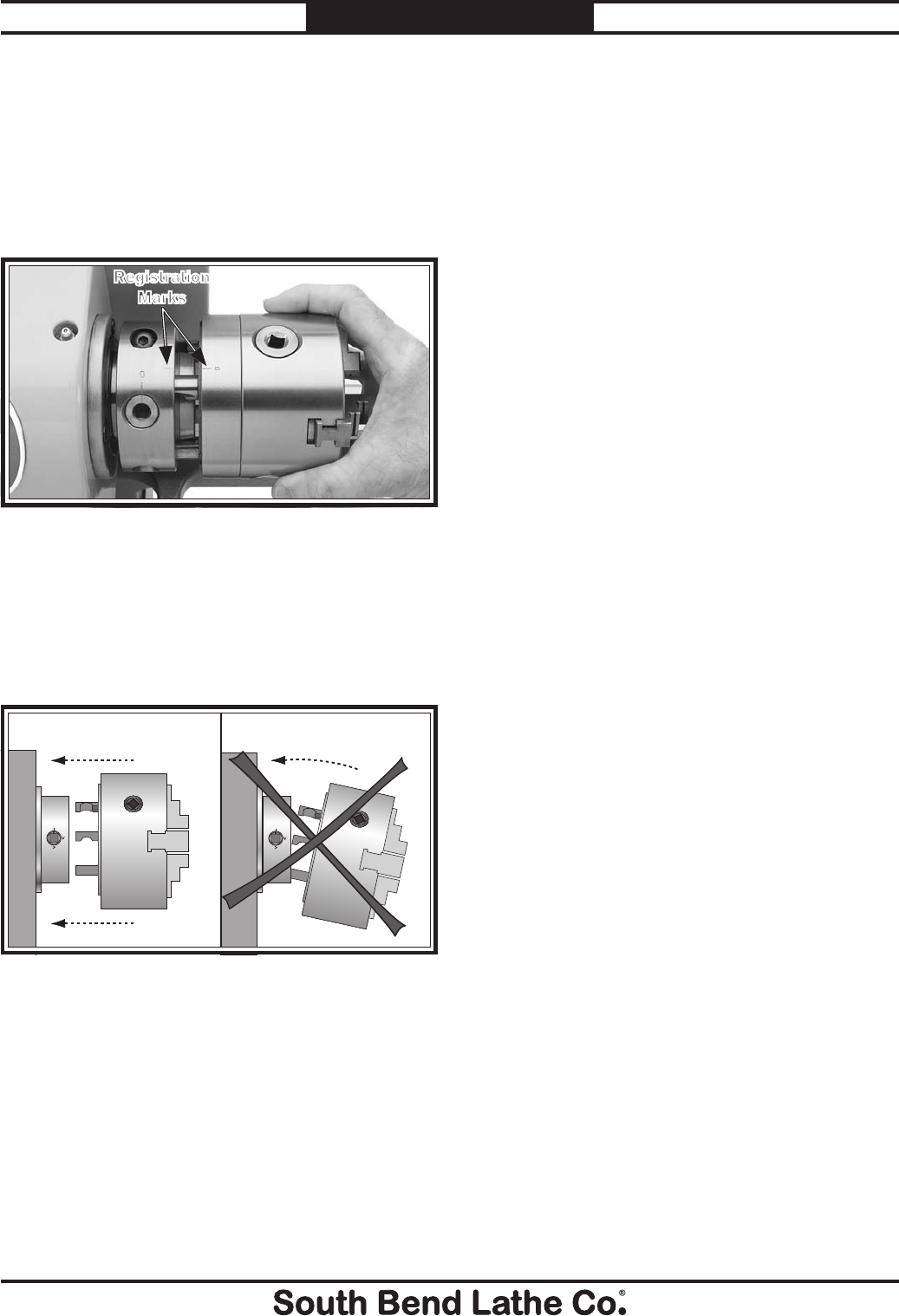

4. Align the registration mark on the chuck

(see Figure 19) with the one on the spindle.

Note: The camlock studs were adjusted at the

factory to correctly fit the corresponding

spindle cam hole, then the registration

marks were made so that the chuck can be

mounted with the same alignment each time.

Figure 20. Inserting camlock studs into spindle cam

holes.

INCORRECTCORRECT

5. Install the chuck by inserting the camlock

studs straight into the spindle cam holes.

Important: Avoid inserting the studs at an

angle—this can damage studs or spindle cam

holes.

6. Incrementally tighten the camlocks in a

criss-cross or star pattern to ensure that the

chuck seats evenly against the spindle.

7. When the chuck is fully seated and all the

camlocks are tight, verify that the chuck fits

the spindle properly by checking for any gaps

between the mating surfaces.

— If there are no gaps, proceed to Step 8.

— If there is a gap, remove the chuck, re-

clean the mating surfaces carefully, and

re-install. If the problem persists, contact

our Tech Support.

8. Verify that the chuck/spindle tapers are

seated firmly together by removing the

chuck, per the Chuck Removal instructions

on the next page, and pay close attention to

how easily the tapers release.

— If it was necessary to bump the chuck or

use a mallet to release the tapers, then

they are seating together properly.

— If the tapers released easily with little

intervention, they are not seated together

firmly as required. Remove the chuck, re-

clean the mating surfaces carefully, and

re-install. If the problem persists, contact

our Tech Support.

Figure 19. Chuck and spindle registration marks.

Registration

Marks