For Machines Mfg. Since 8/11 Model SB1001 8K

™

Lathe

-53-

SERVICE

The lathe must be properly prepared if it will be

stored for any period of time. Doing this will help

prevent the development of rust and corrosion.

and ensure the lathe remains in good condition

for later use.

To prepare the lathe for storage:

1. DISCONNECT LATHE FROM POWER!

2. Thoroughly clean all surfaces, then apply a

heavy coat of way oil to unpainted and bare

metal surfaces.

3. Lubricate the machine as outlined in

Lubrication, beginning on Page 51, then

move/rotate the components through the full

range of motion several times to distribute

the lubricant.

4. Cover the lathe and place it in a dry area

that is out of direct sunlight and away from

hazardous fumes, paint, solvents, or gas that

could damage the surfaces of the lathe.

5. Once or twice a month, move the carriage,

tailstock, and other components mounted on

the bedway down the bed to make sure that

rust is not beginning to occur. If it is, remove

it and re-apply a heavy coat of way oil.

6. Every few months, repeat Step 3.

Machine Storage

After a long period of time, you may find that

the leadscrew develops a small amount of end

play. This end play can be removed with an

adjustment of the lock collars on the right end of

the leadscrew.

Tools Needed: Qty

Hex Wrench 2.5mm ..............................................1

To remove leadscrew end play:

1. DISCONNECT LATHE FROM POWER!

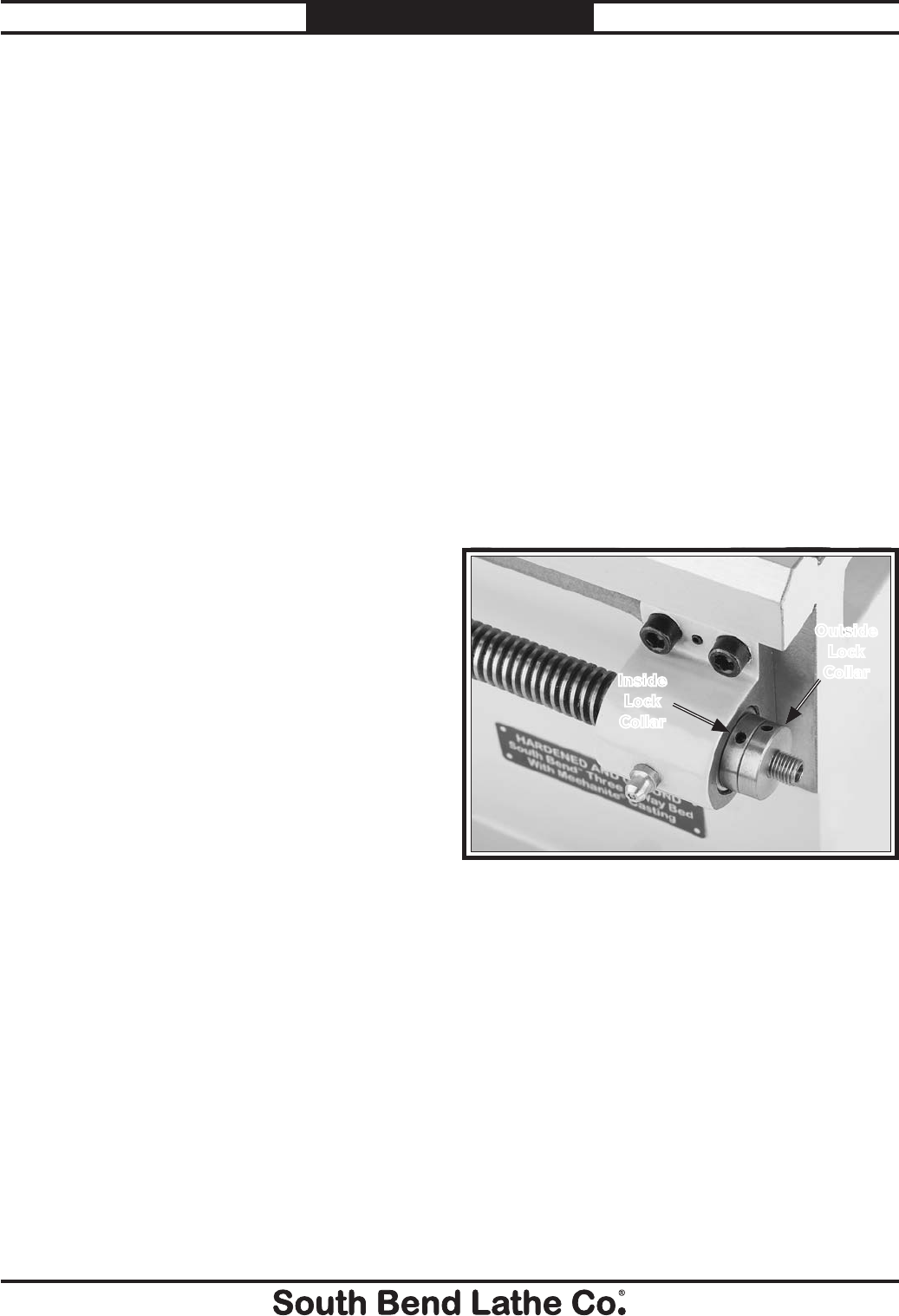

2. Insert the hex wrench or similar tool into a

hole on the rim of the outside leadscrew lock

collar (see Figure 88) to loosen it a couple of

turns.

Leadscrew End Play

Adjustment

Figure 88. Longitudinal leadscrew lock collars.

Outside

Lock

Collar

Inside

Lock

Collar

3. In the same manner, loosen the inside lock

collar a couple of turns.

4. Engage the half nut with the leadscrew,

then use the handwheel to move the carriage

toward the tailstock with slight pressure.

5. Tighten the inside lock collar until it is just

snug, then tighten the outside collar against

it to secure the setting.