For Machines Mfg. Since 8/11 Model SB1001 8K

™

Lathe

-57-

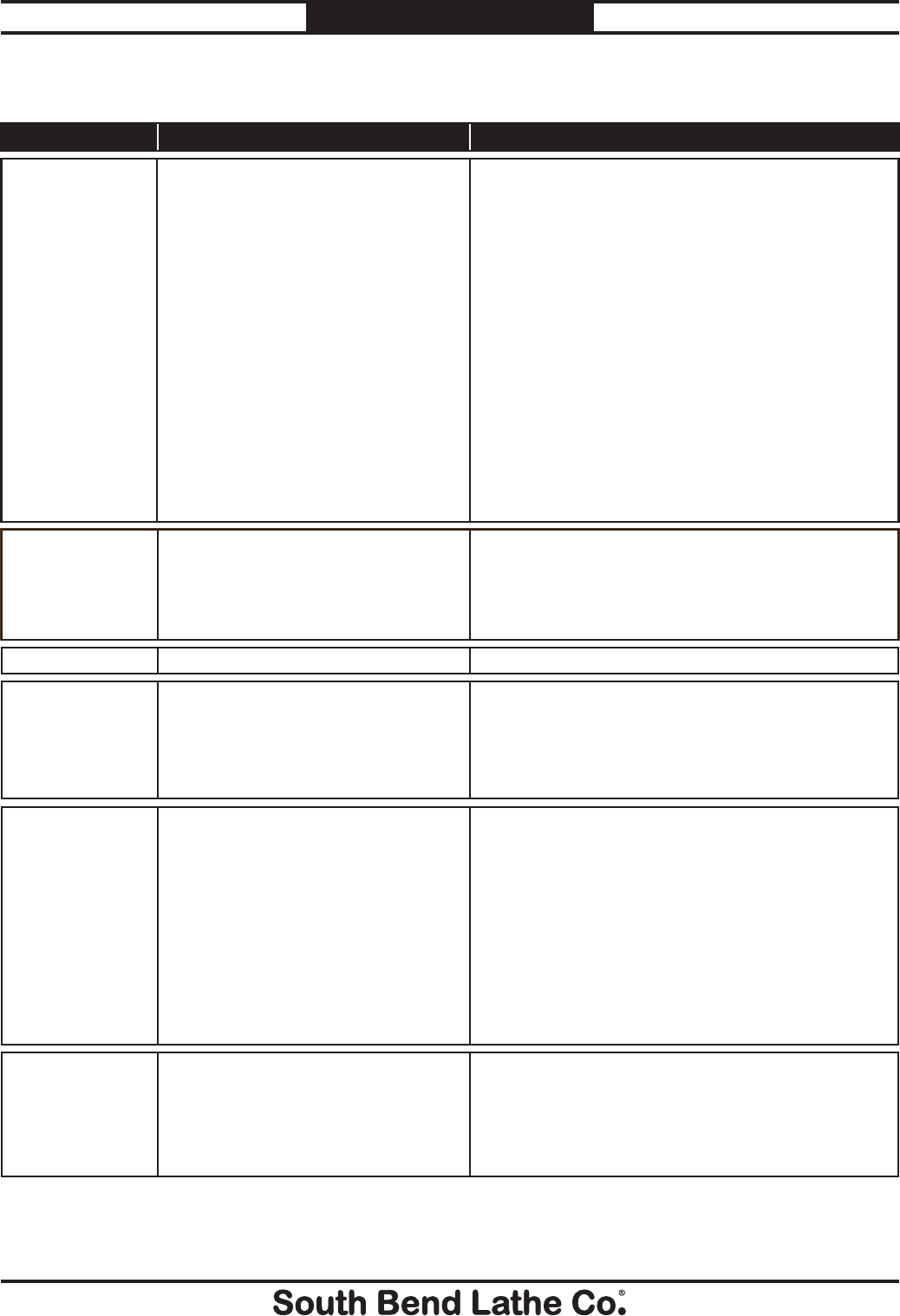

TROUBLESHOOTING

If you need replacement parts, or if you are unsure how to do any of the solutions given here, feel free

to call us at (360) 734-1540.

Symptom Possible Cause Possible Solution

Machine does not

start or a circuit

breaker trips.

1.

STOP button is engaged or at fault.

1.

Rotate STOP button clockwise until it pops out

to reset it for operation; replace if not working

properly.

2. Power supply is switched OFF at

master power switch or breaker.

2.

Make sure master power switch and circuit breaker

are turned ON.

3.

Wall fuse/circuit breaker is blown/

tripped; short in electrical system;

start-up load too high for circuit.

3.

Verify circuit is rated for machine amp load;

troubleshoot and repair cause of overload; replace

weak breaker; find/repair electrical short.

4.

Fuse has blown on circuit board

inside electrical cabinet.

4.

Replace fuse; determine if overload is due to heavy

operation; ensure power source has high enough

voltage and power cord is correctly sized.

5.

Wiring is open/has high resistance.

5.

Check for broken wires or disconnected/corroded

connections, and repair/replace as necessary.

6.

Spindle switch is at fault.

6.

Replace spindle switch.

7.

Spindle speed dial is at fault.

7.

Replace spindle speed dial.

8.

Motor is at fault.

8.

Test/repair/replace.

Loud, repetitious

noise coming from

inside end cover.

1.

Drive or timing belts are loose and

slipping.

1. Re-tension drive belts (see Page 55); re-position

timing-belt pulleys so that the timing belts have

only slight deflection between pulleys.

2.

Timing-belt pulleys are loose or

missing shaft keys.

2.

Re-tighten pulleys and pulley shafts; check/replace

missing shaft keys.

Motor overheats.

1.

Motor overloaded.

1.

Reduce load on motor.

Motor is loud when

cutting, or bogs

down under load.

1.

Excessive depth of cut or feed rate.

1.

Decrease depth of cut or feed rate.

2.

Spindle speed or feed rate wrong for

cutting operation.

2.

Refer to the feeds and speeds charts in

Machinery's Handbook or a speeds and feeds

calculator on the internet.

3.

Cutting tool is dull.

3.

Sharpen or replace the cutting tool.

Entire machine

vibrates upon

startup and while

running.

1.

Workpiece is unbalanced.

1.

Re-install workpiece centered with the spindle bore.

2.

Workpiece is hitting stationary

object.

2.

Stop lathe immediately and correct interference

problem.

3.

Loose or damaged drive belt(s).

3.

Re-tension/replace the drive belt(s) as necessary

(see Page 55).

4.

Drive belt pulleys are not properly

aligned.

4.

Align the drive belt pulleys.

5.

Chuck or faceplate is unbalanced.

5.

Re-balance chuck or faceplate; contact a local

machine shop for help.

6.

Spindle bearings at fault.

6.

Replace worn spindle bearings.

Bad surface finish.

1.

Wrong spindle speed or feed rate.

1.

Adjust for appropriate spindle speed and feed rate.

2.

Cutting tool is dull or incorrect for

operation.

2.

Sharpen or replace the cutting tool; use correct tool

for operation.

3.

Tool height incorrect.

3. Adjust tool height to centerline (see Page 37).

4.

Too much play in gibs.

4. Tighten gibs (see Page 54).