-56-

For Machines Mfg. Since 8/11

Model SB1001 8K

™

Lathe

SERVICE

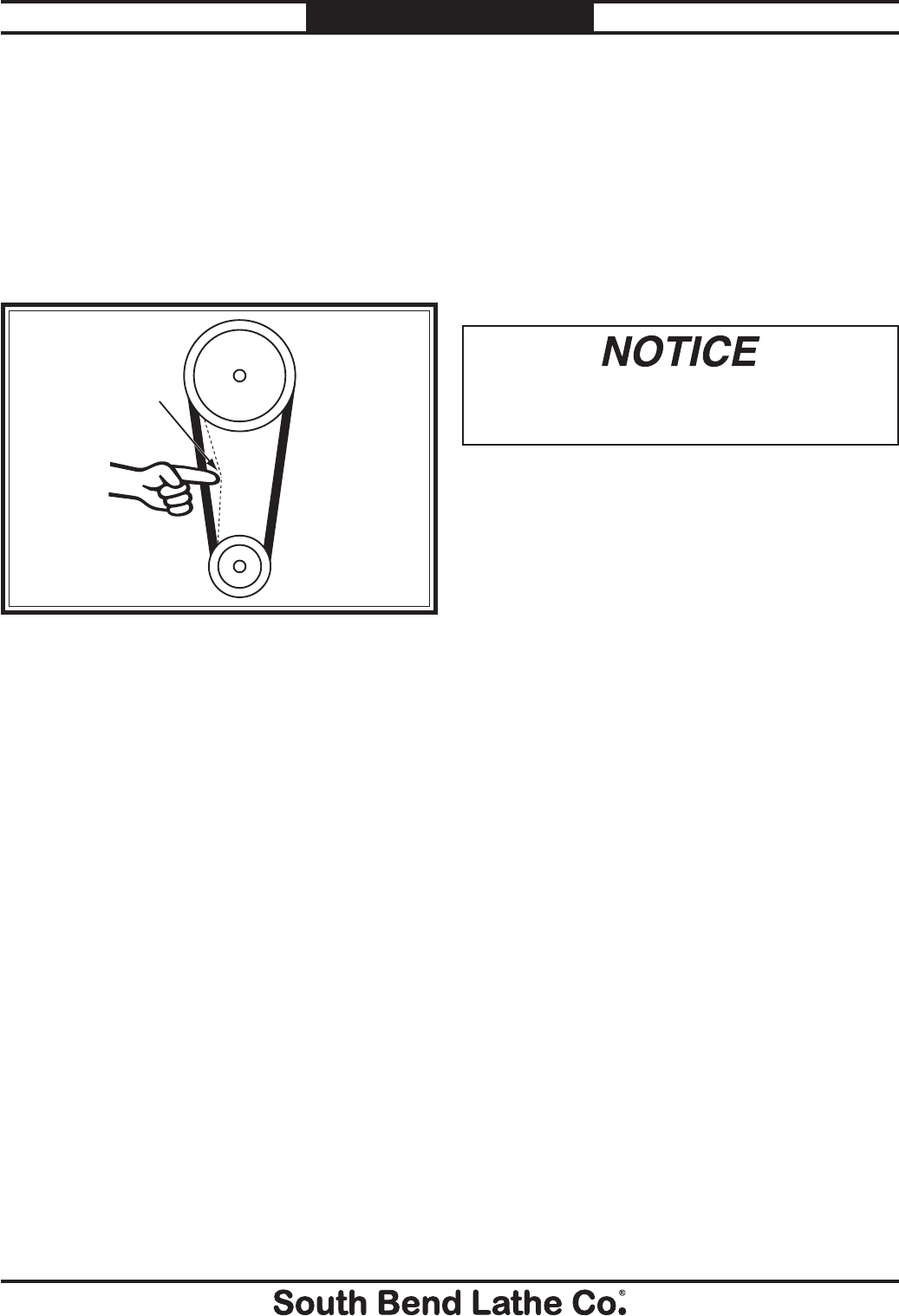

3. Apply moderate pressure on the idler

pulley (see Figure 92) toward the front of

the lathe while turning the tensioning bolt

counterclockwise to lower the idler pulley

and increase belt tension.

The correct amount of belt tension is when

there is approximately

1

⁄4"–

3

⁄8" deflection

with moderate pressure applied to the belt

between the pulleys (see Figure 93).

Figure 93. Testing for correct drive belt tension.

Pulley

Deflection

Pulley

4. When the belt tension is correct, continue

applying pressure on the idler pulley as you

re-tighten the pivot block hex nut to secure

the tension setting.

5. Re-check the tension on both belts, and if

necessary, repeat this procedure until the

correct belt tension is attained.

6. Close the end cover before re-connecting the

lathe to power.

DO NOT overtighten belt tension. This could

cause the machine to run hot and cause

damage to the motor and bearings.