-14-

For Machines Mfg. Since 8/09

Model SB1019

PREPARATION

Lifting & Moving

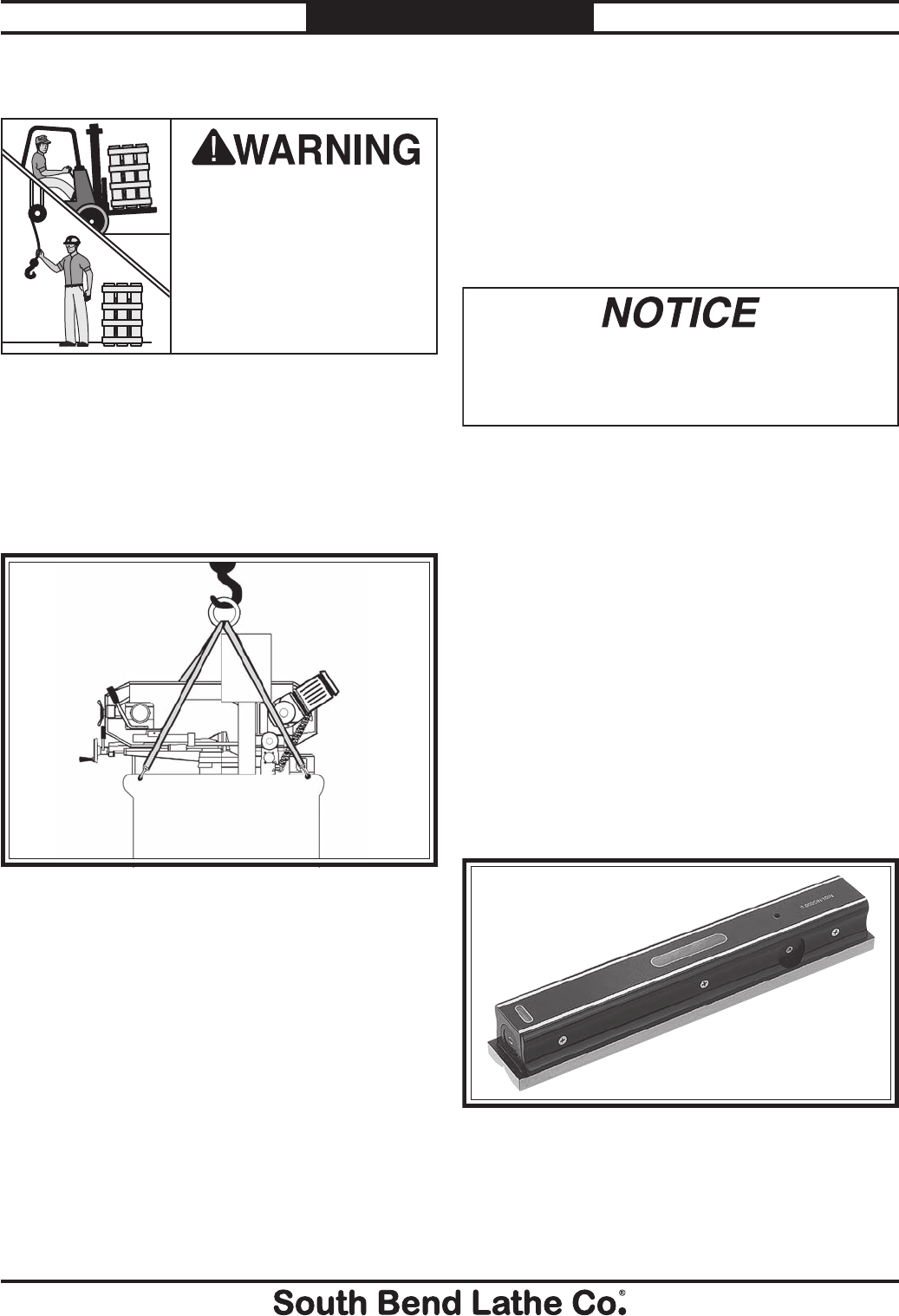

Unbolt the machine from its pallet, then insert

two round steel bars through the lifting holes

in the machine base. Attach lifting straps

with hooks to the bars, as shown in Figure 6.

Lift the machine just high enough to clear the

pallet, then move it to its final location. Have an

assistant stabilize the machine while moving.

Figure 6. Lifting locations.

This machine and its

parts are heavy! Serious

personal injury may occur

if safe moving methods are

not used. To reduce the

risk of a lifting or dropping

injury, ask others for help

and use power equipment.

Leveling & Mounting

Leveling

Figure 7. Example of a precision level.

Leveling machinery helps precision components,

such as bed ways, remain straight and flat

during the lifespan of the machine. Components

on an unleveled machine may slowly twist due to

the dynamic loads placed on the machine during

operation.

For best results, use a precision level that

is at least 12" long and sensitive enough to

show a distinct movement when a 0.003" shim

(approximately the thickness of one sheet of

standard newspaper) is placed under one end of

the level.

See the figure below for an example of a high

precision level.

We strongly recommend securing your

machine to the floor if it is hardwired to the

power source. Consult with your electrician to

ensure compliance with local codes.

Generally, you can either bolt your machine

to the floor or mount it on machine mounts.

Although not required, we recommend that you

secure the machine to the floor and level it while

doing so. Because this is an optional step and

floor materials may vary, hardware for securing

the machine to the floor is not included.