-40-

For Machines Mfg. Since 8/09

Model SB1019

SERVICE

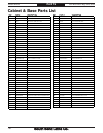

The swivel base is equipped with three angle

stops to provide quick adjustments to 45°L, 0°,

and 45°R (Figure 42). If cuts made using these

stops are not sufficiently accurate, the stops will

need to be adjusted.

Adjusting Angle Stops

Figure 42. Angle stops.

45°L Angle

Stop

45°R Angle

Stop

0° Angle

Stop

Jam Nut

Stop Bolt

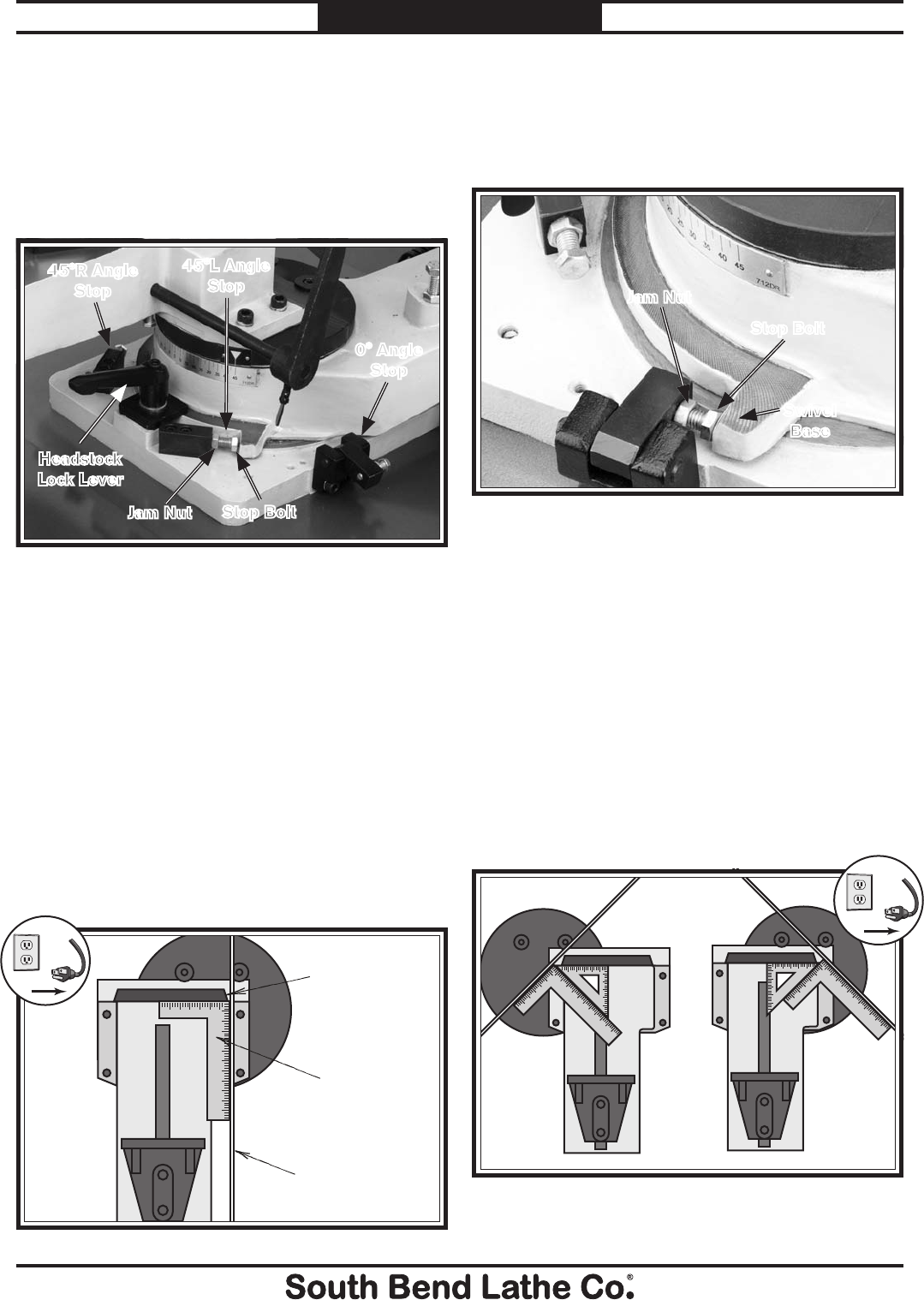

Figure 44. Stop adjustment.

Jam Nut

Stop Bolt

To adjust the angle stops:

1. DISCONNECT BANDSAW FROM POWER!

2. Rotate the headstock to the right

approximately 10°, engage the 0° angle

stop by flipping it towards the vise, then

rotate the headstock to the left until it stops

against the 0° stop. Tighten the headstock

lock lever.

3. Lower the headstock, then place a square

flat on the table and against both the

stationary jaw and the blade, as shown in

Figure 43.

4. If the square does not fit snugly against both

the stationary jaw and the blade, loosen the

jam nut shown in Figure 44 several turns,

then thread the stop bolt inward several

turns.

Figure 43. Testing vise/blade squareness.

Stationary Jaw

Square

Blade

45°R

45°L

Headstock

Lock Lever

5. Loosen the headstock lock lever, rotate the

headstock so that the blade is square to

the vise, then re-tighten the headstock lock

lever.

6. Adjust the stop bolt as needed until it just

touches the cast iron swivel base, as shown

in Figure 44, then snug the jam nut against

the stop block without turning the stop bolt.

7. Repeat this procedure for the 45°R and 45°L

stops using a square and a 45° triangle (or

an adjustable square), as shown in Figure

45.

Swivel

Base

Figure 45. 45°L and 45°R stop adjustment.

Stationary Jaw

Square

Blade

45°R

45°L

!

!