OPERATION

PLACE THE MODE SWITCH (on units so equipped) in the “MAN.” position and energize

the xenon power supply. The lamphouse blower will start and actuate the blower interlock switch to permit bulb

ignition. This lamp blower will operate continuously until the xenon power supply is de-energized.

PLACE THE LAMP SWITCH in the ON position and the xenon bulb will ignite. Allow a few

minutes for the current to stabilize, and read the lamphouse ammeter. The 700 watt xenon bulb must be

operated within the current range specified by the bulb manufacturer, normally 36 amperes nominal; maximum

current 40 amperes. Refer to the manufacturer’s documents shipped with the bulb for the exact figures.

ADJUST THE POWER SUPPLY as instructed in the power supply manual for the correct

operating current. New 700 watt bulbs are normally first operated at their nominal current level (36 A.). The

current setting must be increased in time to compensate for bulb aging, but do not, at any time, exceed the

maximum current rating (40 A.).

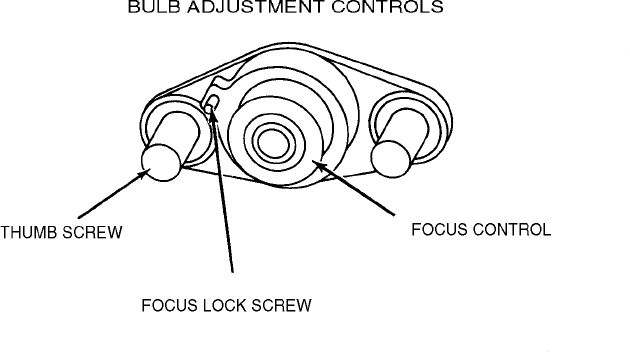

REMOVE THE REAR COVER PANEL (two pull type knobs) located below the instrument

panel. This will expose the bulb position adjustment controls.

THE CENTER SECTION of the control is a threaded member that focuses the bulb in relation

to the reflector. Turning this adjustment moves the bulb on the horizontal plane, into or out of the reflector.

Rotating this section clockwise moves the bulb away from the reflector. The small knurled screw to the left of

this section can be tightened to lock the focusing mechanism in place after the bulb alignment procedure has

been completed.

THE THUMB SCREWS to the left and right of the focusing control lock the horizontal and

vertical position of the bulb. These thumb screws are spring-loaded to apply a degree of friction against the

lamphouse back casting.

TWO METHODS are recommended to align the bulb in order to project the best light to the stage: